Method for measuring position and speed of rotor of electrically excited synchronous motor and control device

A technology of synchronous motor and rotor position, which is applied to devices using electric/magnetic methods, single motor speed/torque control, and wound-type excitation motor control. It can solve the problems of complex hardware structure of the speed closed-loop control system. Achieve the effects of improving reliability and speed control accuracy, simplifying system structure, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: The measurement method for measuring the rotor position and speed of an electrically excited synchronous motor is:

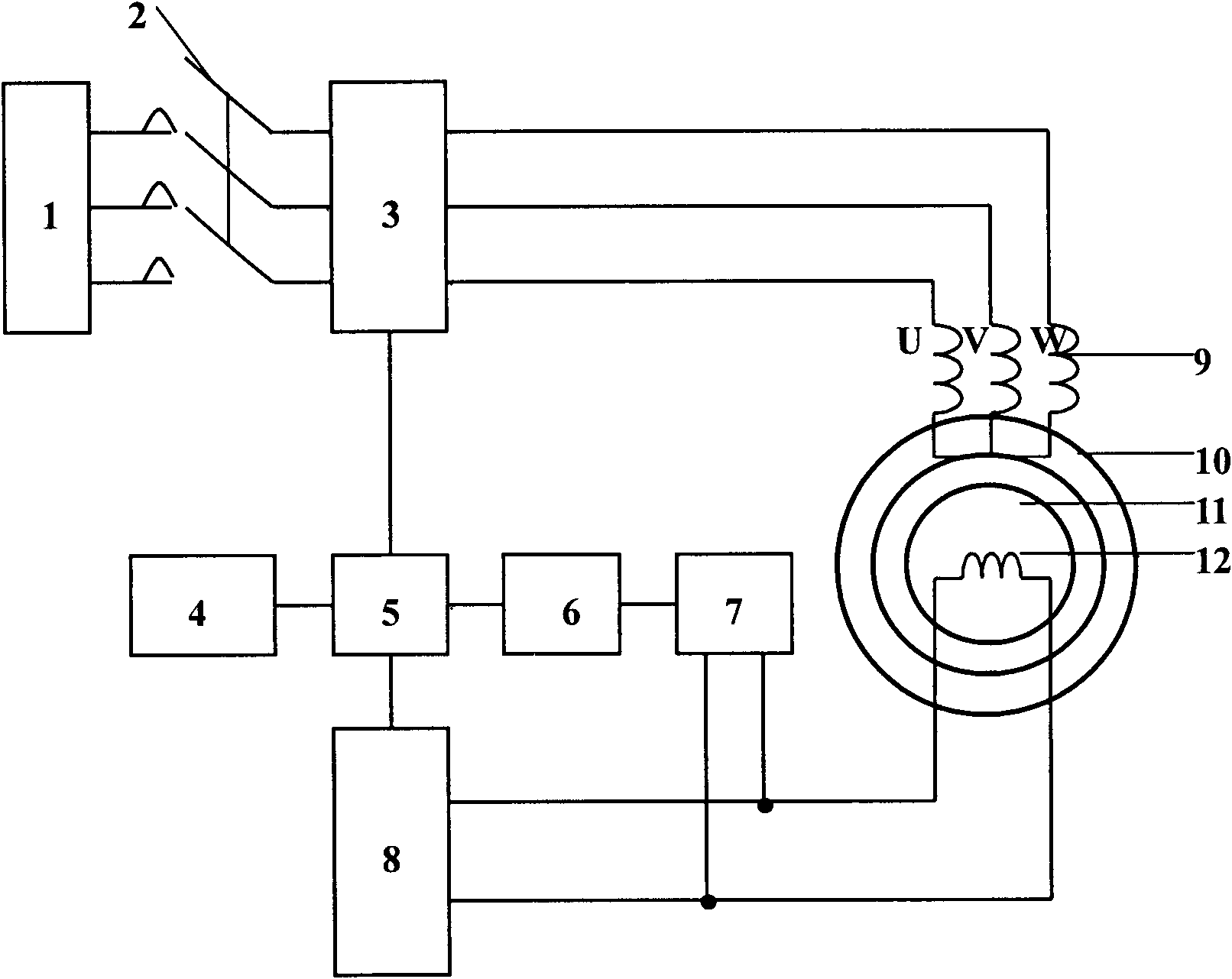

[0022] a. The system controller 5 controls the stator power converter 3. On the one hand, the stator power converter 3 outputs a three-phase AC voltage to supply power to the stator winding 9 of the synchronous motor; H high-frequency voltage signal;

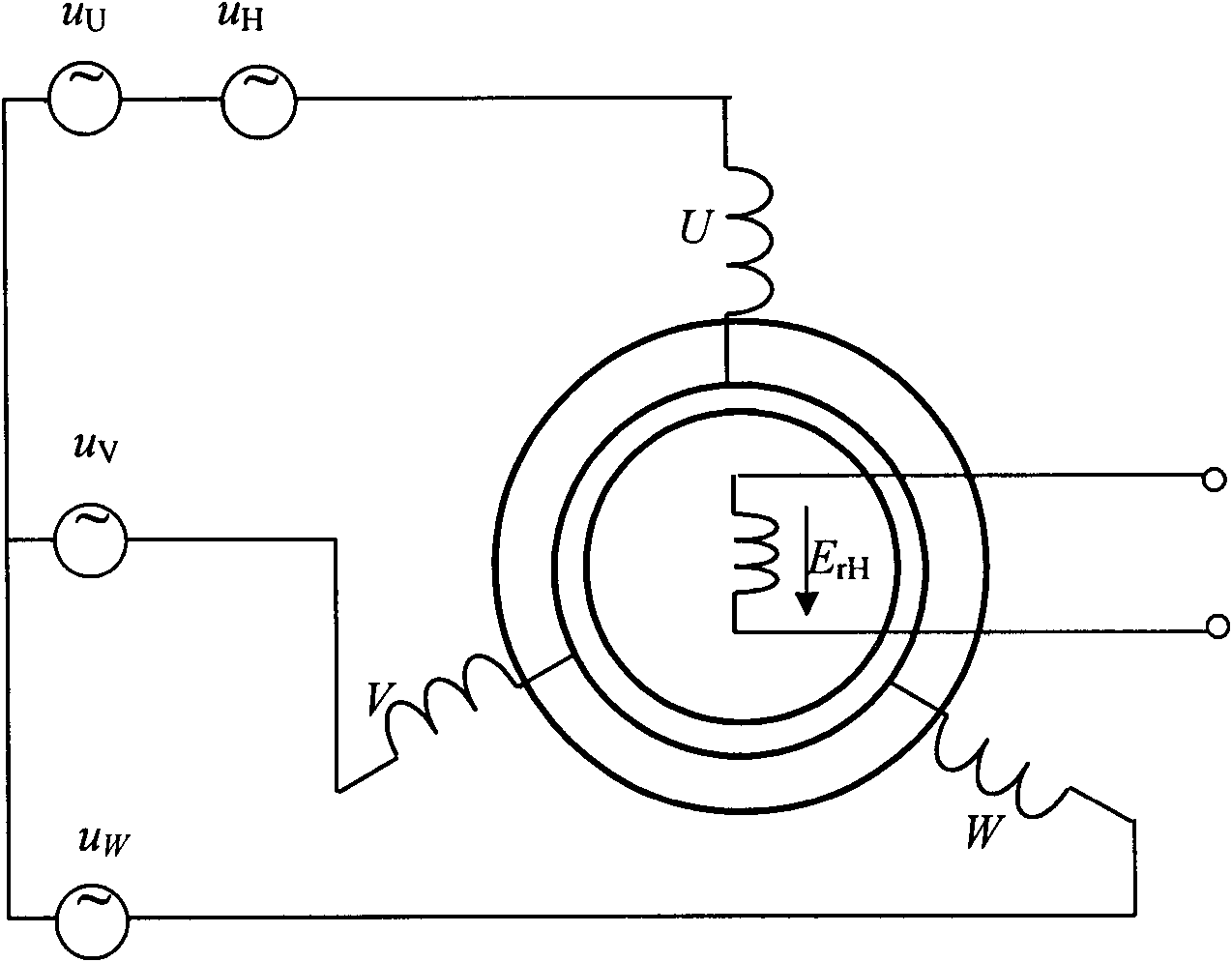

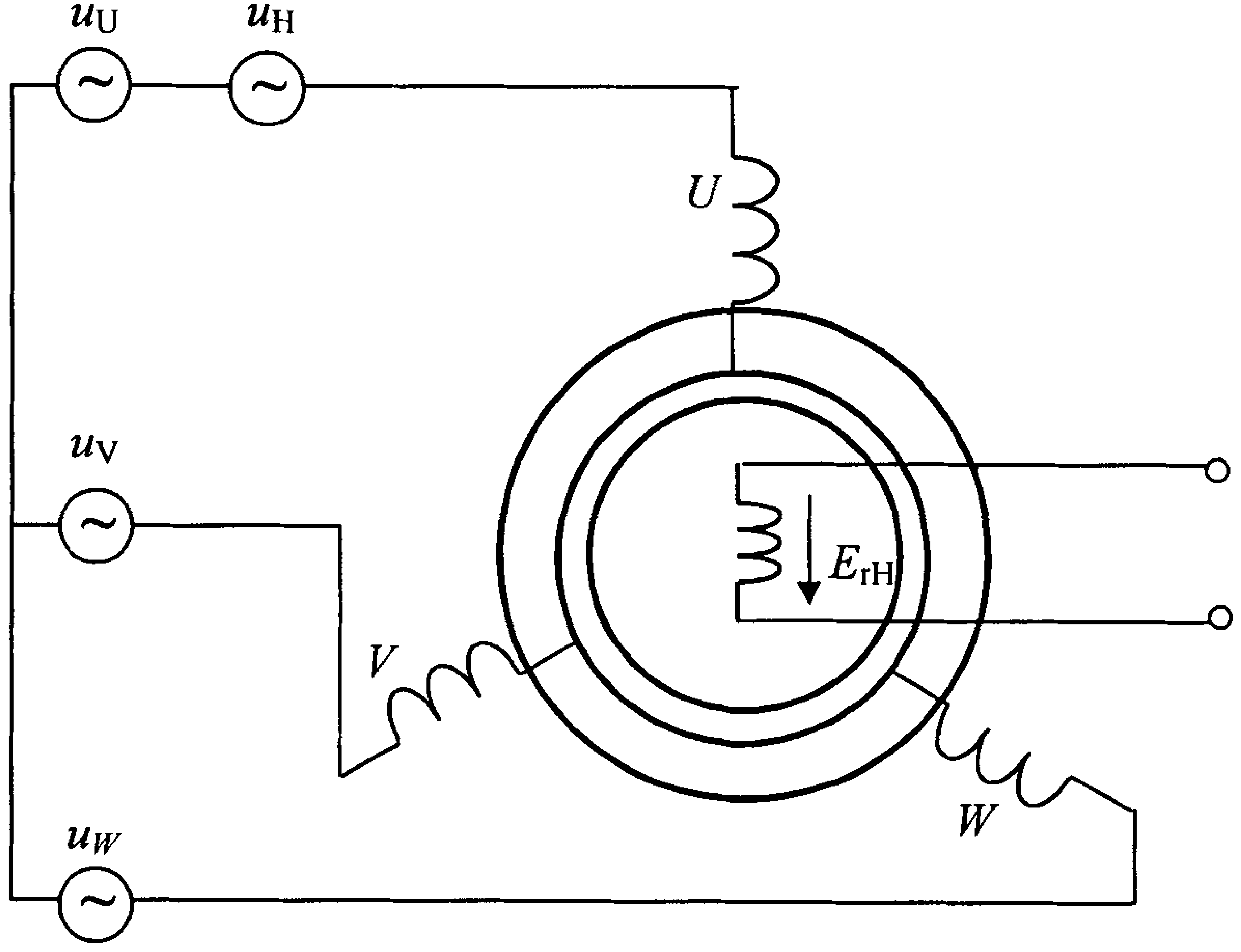

[0023] b. The injection frequency is f in the phase U of the stator winding of the synchronous motor H The high-frequency excitation signal, the frequency induced from the synchronous motor rotor excitation winding 12 and the cosine relationship with the rotor angle θ is f H high-frequency potential signal;

[0024] c, the signal filter 6 extracts the frequency detected by the voltage transformer 7 as f H The high-frequency potential signal of the system controller 5 calculates the rotor position angle of the synchronous motor, and uses the derivative of the rotor angle θ to time to calcula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com