Plate type reactor, manufacturing method therefor, and reaction product manufacturing method using the plate type reactor

A technology for plate reactors and reaction products, which is applied in chemical instruments and methods, preparation of organic compounds, preparation of oxygenated compounds by oxidation of hydrocarbons, etc., and can solve the problems of reduced yield of target reaction products, pressure rise, and large pressure loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

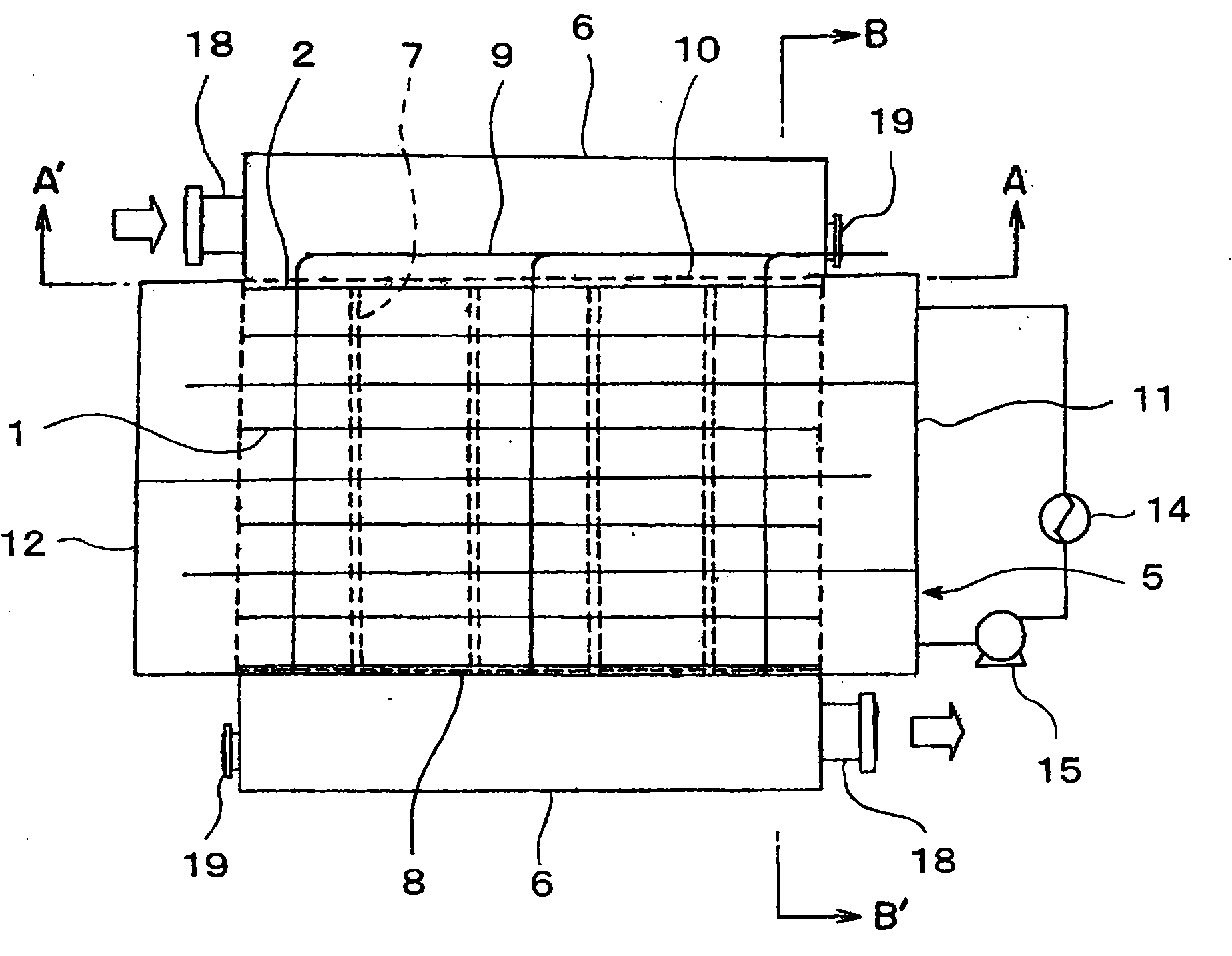

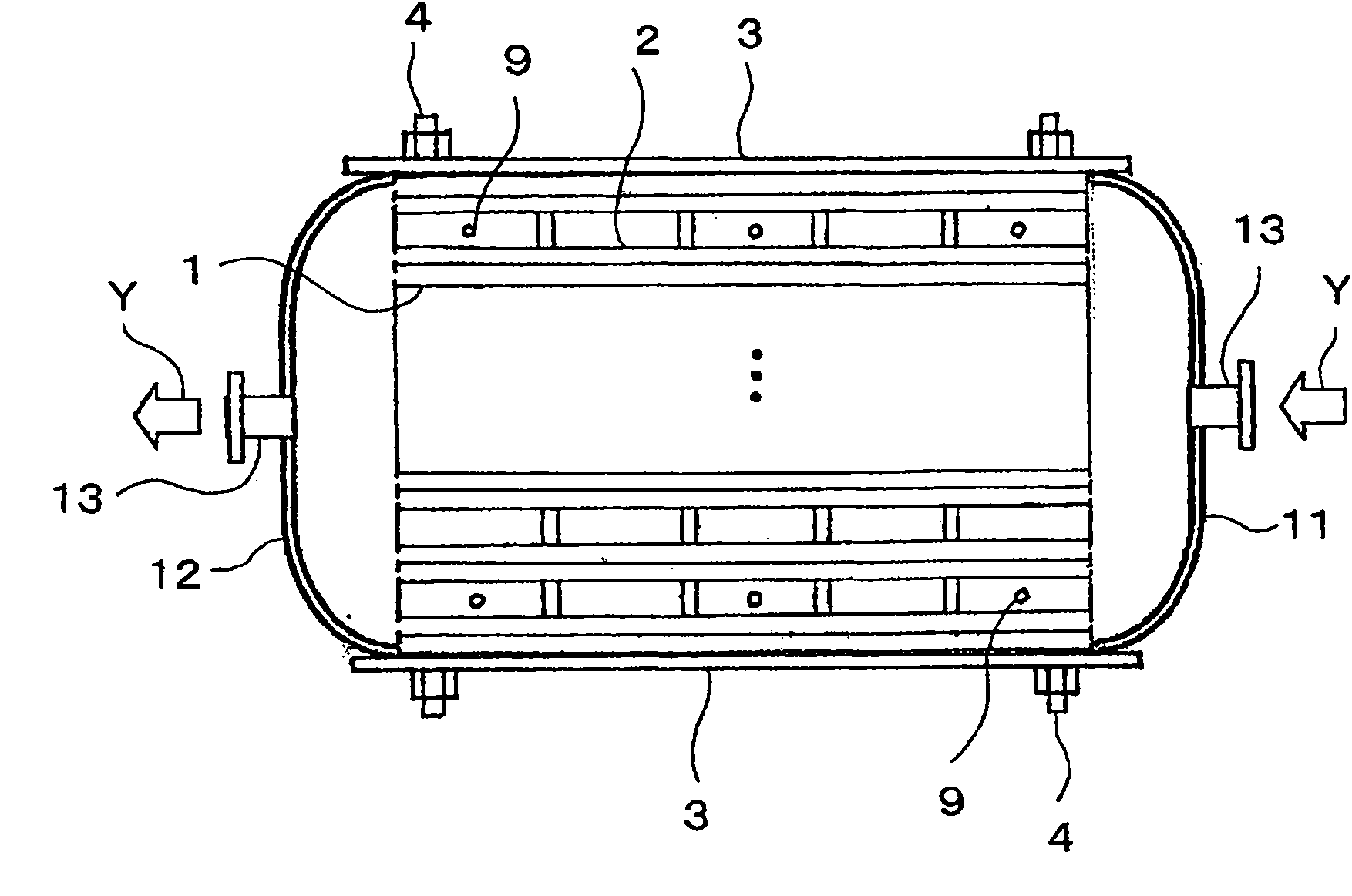

[0250] For example Figure 1 ~ Figure 4 As shown, the first plate reactor has the following components: more than 2 heat transfer plates 2, which are arranged side by side in the above-mentioned reaction vessel, and have heat transfer tubes 1; a pair of clamping plates 3, The pair of clamping plates 3 is at least in contact with the heat transfer plates 2 at both ends of the heat transfer plates 2 along the axis of the heat transfer tube 1, and clamps two or more heat transfer plates 2 in the direction of the heat transfer plates 2. Heat plate 2; two or more holding rods 4, the two or more holding rods 4 connect these clamping plates 3; heat medium supply device 5, the heat medium supply device 5 and the heat transfer tube 1 on the heat transfer plate 2 The two ends are in contact with each other, and heat medium is supplied to the heat transfer tube 1; the gas distribution part 6, the gas distribution part 6 covers the two ends of more than two heat transfer plates 2 in a dir...

no. 2 approach

[0328] Such as Figures 13 to 15 As shown, the second plate reactor has: a rectangular shell 44; more than two heat transfer plates 2 that have heat transfer tubes 1 and are arranged opposite to each other in the shell 44; The heat medium housing part 45; the gap between the adjacent heat transfer plates 2 is divided along the ventilation direction in the shell 44 into two or more partitions 7 that fill and hold the catalyst in two or more sections; The perforated plates 10, 46 on the upper and lower parts of the plate 2; the pump 15 for circulating the heat medium body in the heat medium body container 45; and the temperature adjustment device 47 for adjusting the temperature of the circulating heat medium body .

[0329] The casing 44 forms a gas passage with a rectangular cross-sectional shape, and corresponds to the above-mentioned reaction container. In the casing 44, a pair of vent holes 48, 48' opposite to each other are provided at the upper end and the lower end of ...

no. 3 approach

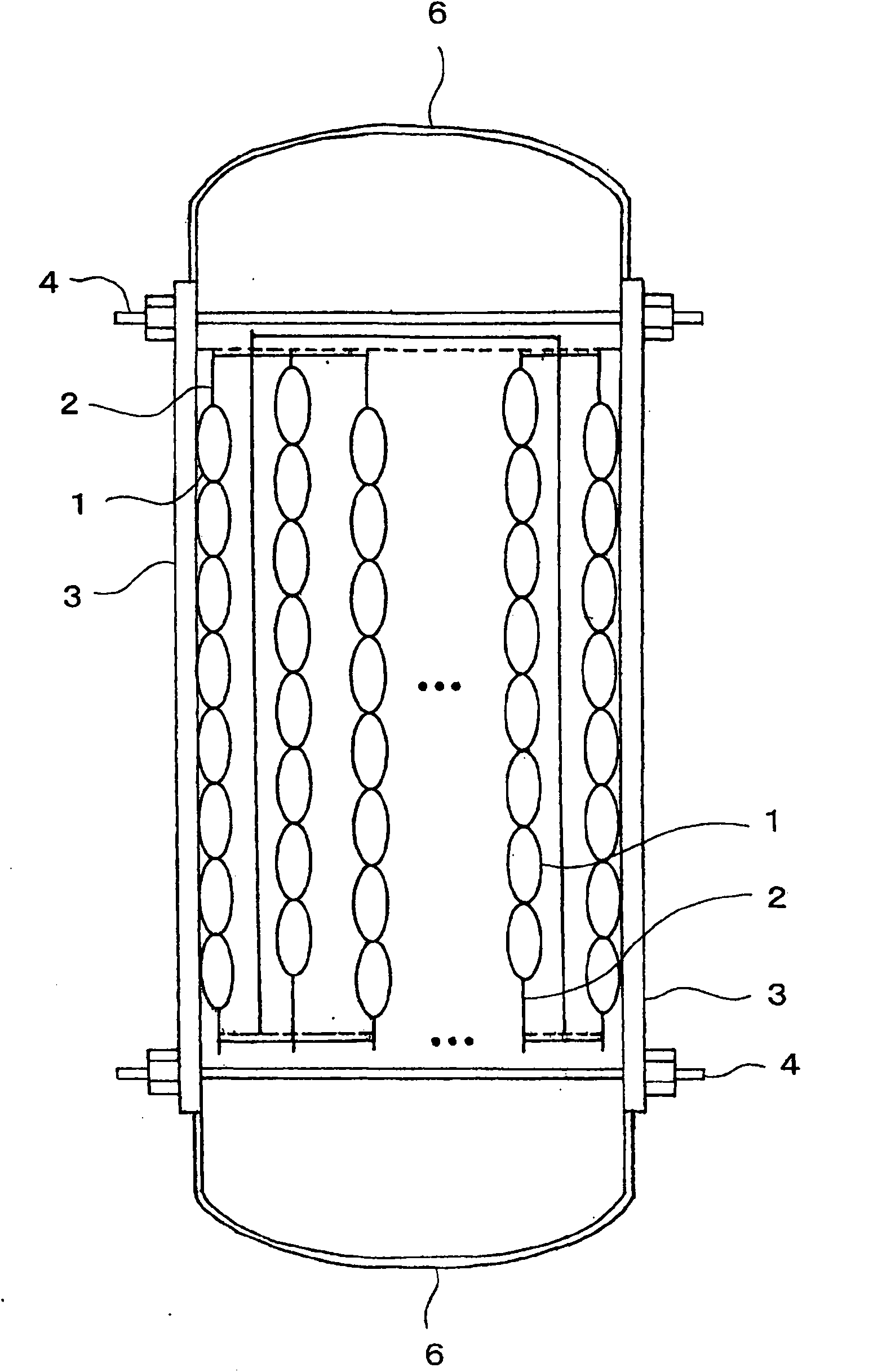

[0350] Such as Figures 23 to 25 As shown, in the second plate reactor, for example, instead of the perforated plate 46, there are two or more vent plugs 8 that are gas-permeable and block the lower end of each section. In addition, there is a plate reaction with the above-mentioned second form. device with the same configuration.

[0351] In the present embodiment, the casing 44 forms an air passage having a rectangular cross-sectional shape, and corresponds to the reaction container described above. The shell 44 has a pair of vents 48, 48' opposite to each other at the upper end and the lower end of the shell 44, and consists of a shell end 49 containing the vent 48, a shell end 49' containing the vent 48', and a heat transfer chamber. Board 2 constitutes the housing body. The housing end portions 49, 49' are each detachably connected to the housing main body. The heat transfer tube 1 is, for example, a tube having an elliptical cross-sectional shape with a major diameter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com