Metal-core thermoelectric cooling and power generation device

A thermoelectric cooler and thermoelectric technology, which is applied in the manufacture/processing of thermoelectric devices, thermoelectric device components, and thermoelectric devices, and can solve the problems of increased contact resistance and packaging complexity and limitations of thin-film thermoelectric cooling devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

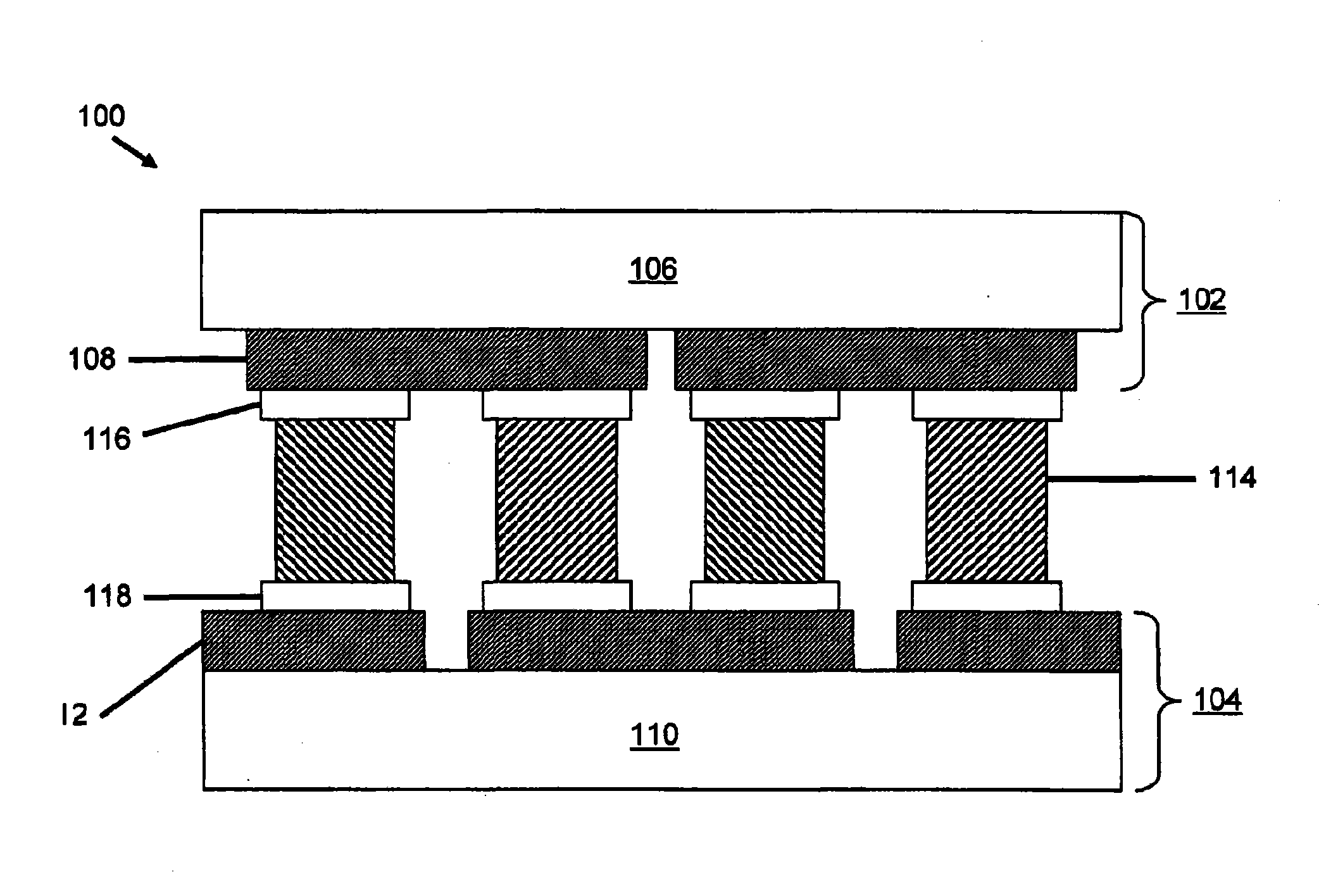

[0018] FIG. 1 shows a cross-sectional view of a conventional thermoelectric cooling device 100 .

[0019] Conventional thermoelectric devices have one or more thermoelectric elements positioned between layers, connected to a source of direct current (DC) current. Conventional thermoelectric device 100 includes a first portion 102 and a second portion 104 . The first part 102 comprises a first layer 106 made of a material having a high thermal conductivity and a low electrical conductivity. Typically, the first layer 106 is made of aluminum nitride or thin alumina ceramic. The first portion 102 also includes a second layer 108, which is a metal interconnect having high thermal and electrical conductivity, connecting the first layer 106 to one or more thermoelectric elements. Typical examples of such materials include, but are not limited to: copper, nickel, and aluminum. Like first portion 102 , second portion 104 includes third layer 110 and fourth layer 112 . The third la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com