Volatile component rectifying-extracting coupled extraction device and method

A technology for volatile components and extraction devices, which is applied in the field of extraction devices for volatile components in plants or Chinese medicinal materials, can solve the problems of reduced yield, high cost, and difficult precipitation of volatile components, so as to shorten the process flow and improve Extraction efficiency, loss reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

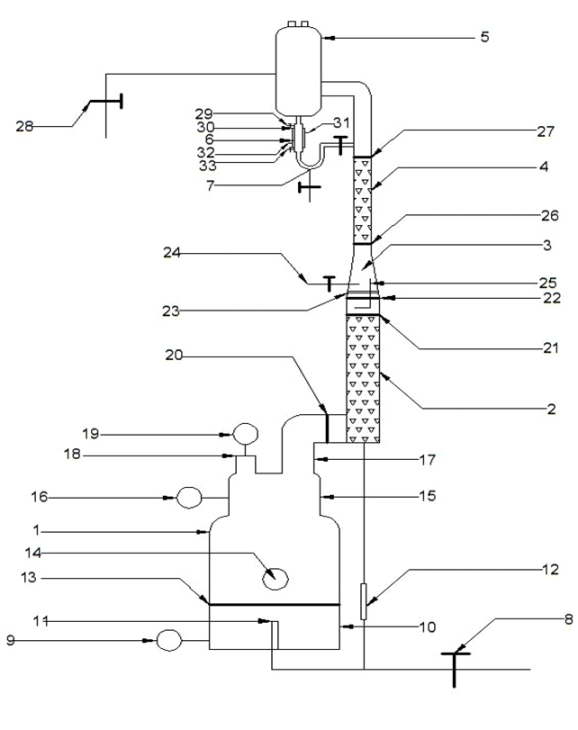

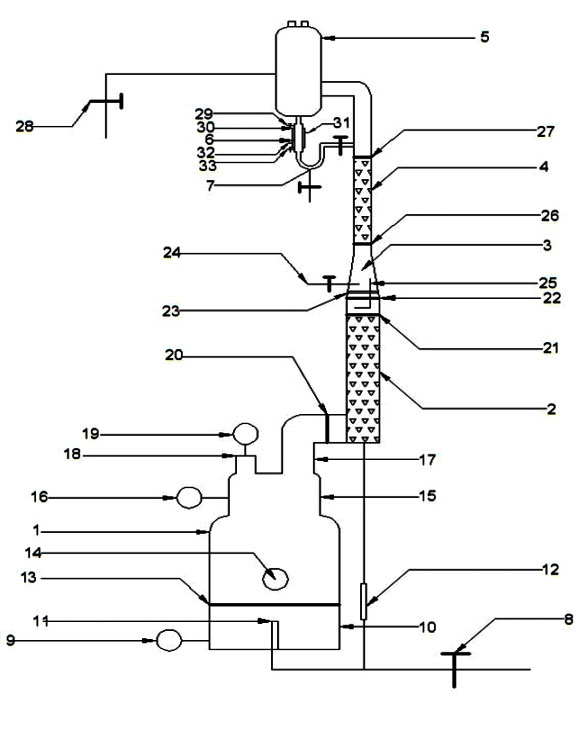

[0049] Take 1 kg of Ligusticum Chuanxiong and grind it to 1 cm × 1 cm × 0.5 cm and add it to the extraction tank 1, then add 10 L of water, turn on the first heating device 10 at the bottom of the extraction tank 1 and the second heating device 15 heating device on the side wall of the extraction tank 1, and Turn on the condensed water switches of the condensing coil 23 and the condenser 5 in turn, stop heating when reflux liquid appears in the oil-water separator 6 and the liquid level is stable, and close the condensing coil 23 and the condenser 5, and soak for 12 hours.

[0050] After soaking, open the first nozzle 29 of the oil-water separator 6, add 11.4ml of mixed volatile oil of the four herbs of Atractylodes atractylodes, notopterygium, frankincense, and myrrh (dosing according to the formula ratio of Jingfukang preparation), and turn on the condensation coil in turn 23. The condensed water switch of the condenser 5 and the condensing pipe 30, and turn on the first heat...

Embodiment 2

[0052] Take 2 kg of Rhizoma Chuanxiong and grind it to 1 cm × 1 cm × 0.5 cm and add it to the extraction tank 1, then add 20 L of water, turn on the first heating device 10 at the bottom of the extraction tank 1 and the second heating device 15 heating device on the side wall of the extraction tank 1, and Turn on the condensed water switches of the condensing coil 23 and the condenser 5 in turn, stop heating when reflux liquid appears in the oil-water separator 6 and the liquid level is stable, and close the condensing coil 23 and the condenser 5, and soak for 12 hours.

[0053] After soaking, open the first branch nozzle 29 of the oil-water separator 6, add 10ml of n-hexane, turn on the condensed water switches of the condensing coil 23, the condenser 5 and the condensing pipe 30 in turn, and turn on the first heating device at the bottom of the extraction tank 1 10. Extract for 20 hours under the full reflux state. After the extraction, close the first heating device 10, open...

Embodiment 3

[0056] The volatile components of curcuma were extracted by water separation method. Add 1 kg of Zedoary Curcuma to the extraction tank 1, then add 8 L of water, turn on the first heating device 10 at the bottom of the extraction tank 1 and the second heating device 15 heating device on the side wall of the extraction tank 1, and turn on the condensation coil 23 and the condensation coil successively. The condensed water switch of device 5, stop heating when reflux liquid appears in the oil-water separator 6 and the liquid level is stable, and close condensing coil 23 and condenser 5, soak for 24 hours.

[0057] Take out the curcuma medicinal material from the discharge port 14 of the extraction tank 1, crush the medicinal material to 2cm×2cm×0.5cm, and add it into the extraction tank 1 again.

[0058] Afterwards, open the first branch nozzle 29 of the oil-water separator 6, add 10ml of normal hexane, turn on the condensation water switch of the condensation coil 23, the conde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com