Catalytic cracking reaction system process simulation optimization model and solution method thereof

A reaction system and catalytic cracking technology, applied in the field of petrochemical process simulation and optimization, can solve problems such as inconvenience of application, integration, and decrease in the accuracy of calculation and simulation results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The present invention is described in further detail in conjunction with accompanying drawing:

[0065] The solution environment of the catalytic cracking reaction system simulation optimization model of the present invention is AspenPlus TM Process simulation software, other software can also be used if it provides the required user model programming interface.

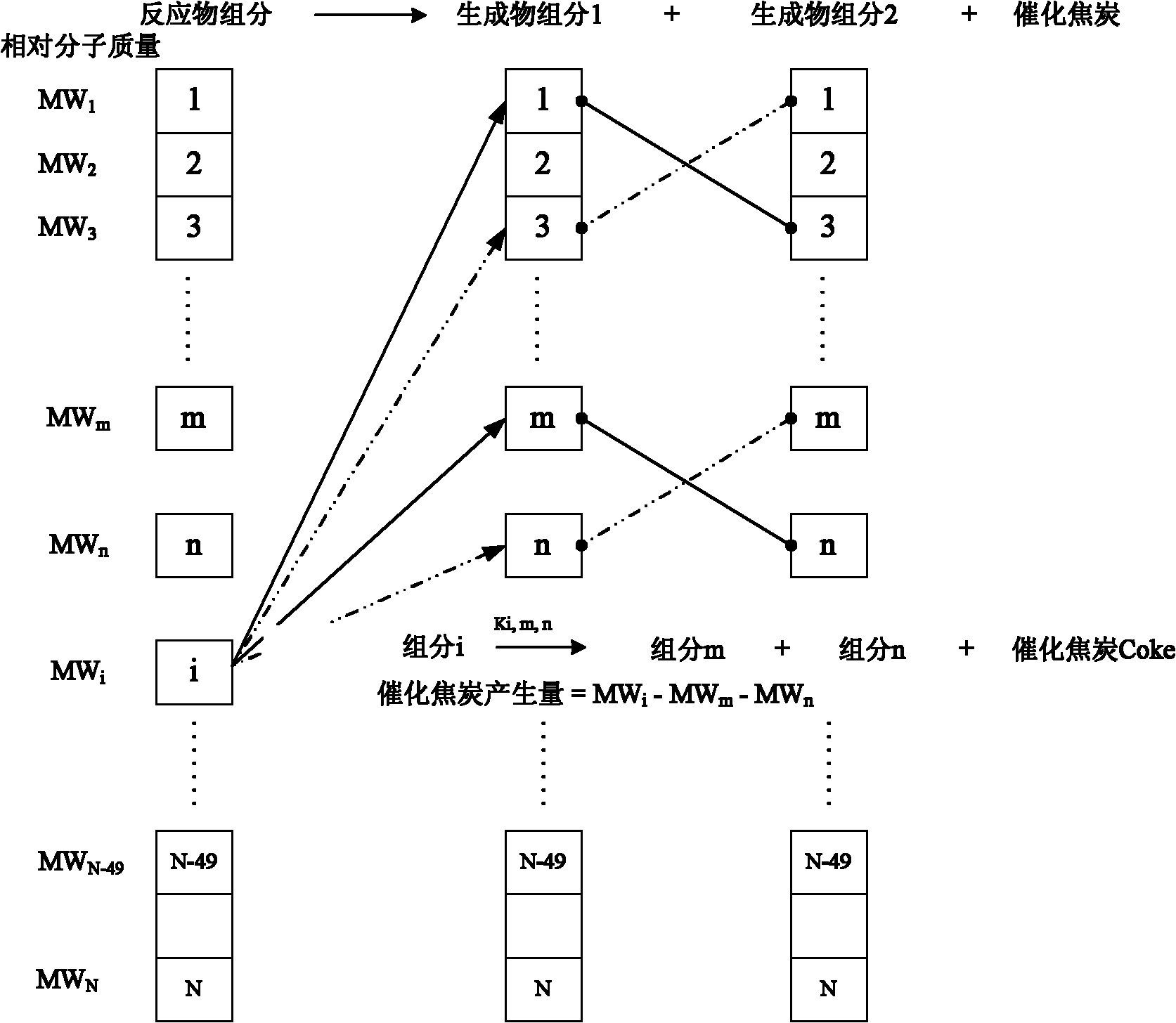

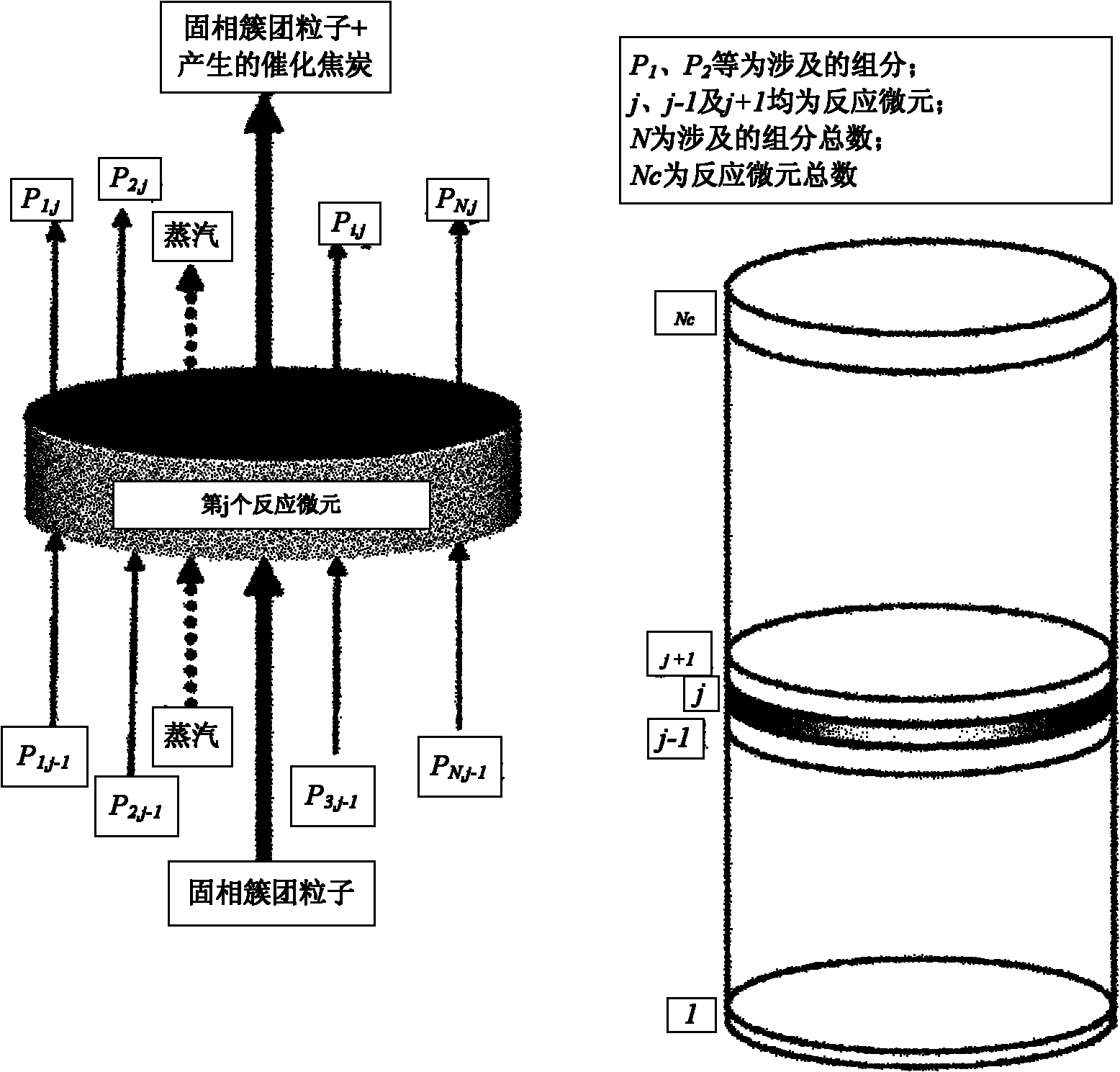

[0066] figure 1 is a real component or virtual group cracking reaction network, assuming that the reactions in the reaction system are all cracking reactions, and one unit of component i is cracked to generate one unit of component m and one unit of component n. The cracking reaction kinetic model involved in the solution process is provided by Gupta et al. [Gupta et al. A new generic approach for the modeling of fluid catalytic cracking (FCC) riser reactor. Association model.

[0067] For the material balance equation, it is calculated according to the following formula:

[0068] For the non-participating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com