Ink composition for printing, paper container material using the ink composition, and heat insulating foamed paper container

一种油墨组合物、容器材料的技术,应用在食物加热容器、容器、油墨等方向,能够解决损害商品性、无法得到、无法读取条形码等问题,达到改善印刷层、表面平滑、外观优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0157] 1. Preparation of white ink

[0158] By mixing 27.2 parts of polyurethane resin A obtained in Preparation Example 1, 40 parts of white pigment (titanium oxide, TITANIX JR800 (manufactured by TAYCA Co., Ltd.), and 67.2 parts of methylcyclohexane: isopropanol : Ethyl acetate = 40:40:20 (weight ratio) mixed solvent, using a sand mill to disperse and knead to prepare the white ink for the base.

[0159] 2. Preparation of red ink

[0160]By mixing 29.2 parts of polyurethane resin A obtained in Preparation Example 1, 15 parts of red pigment (LIONOL RED 6B FG-4300 (manufactured by Toyo Ink Manufacturing Co., Ltd.), and 47.2 parts of methyl ring Hexane: isopropanol: ethyl acetate=40:40:20 (weight ratio) after the mixed solvent of composition, utilize sand mill to disperse kneading, obtain varnish. Then, by adding 0.9 part Silica (Sylophobic 200, (Fuji Silicon Chemical Co., Ltd., particle size: 3.9 μm)) was thoroughly stirred to prepare a red ink for overlay printing.

[0161...

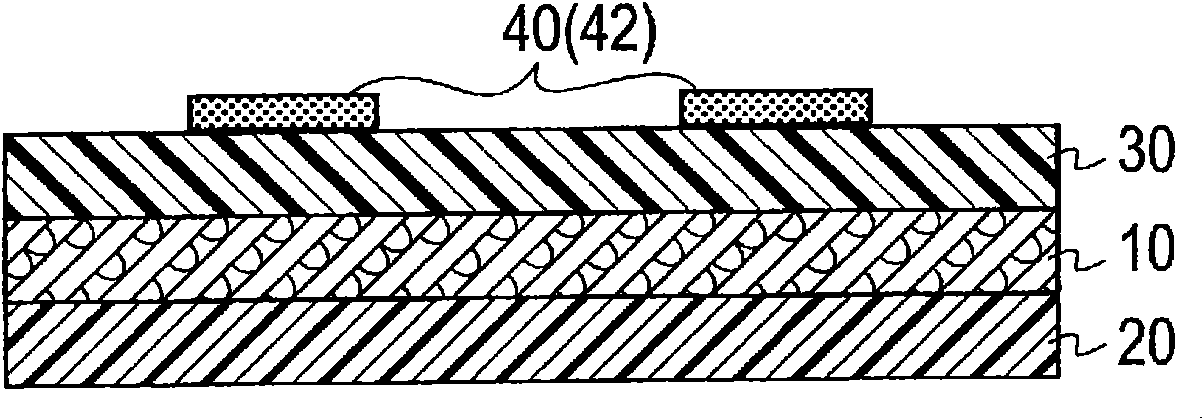

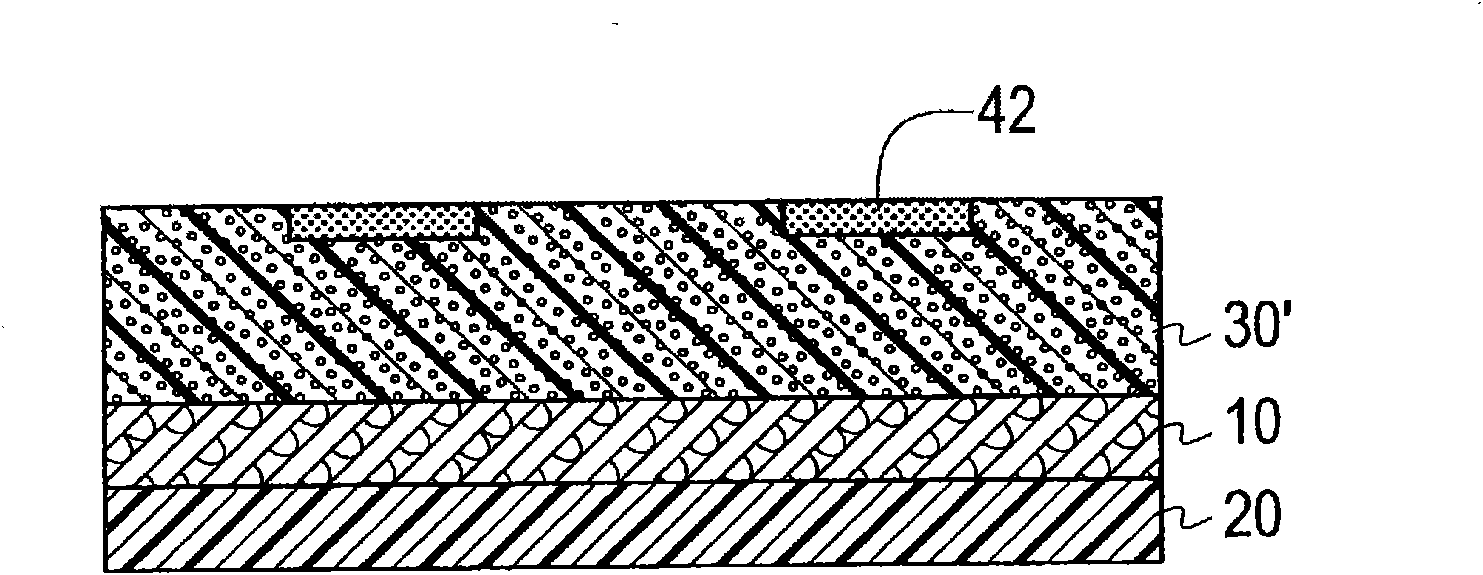

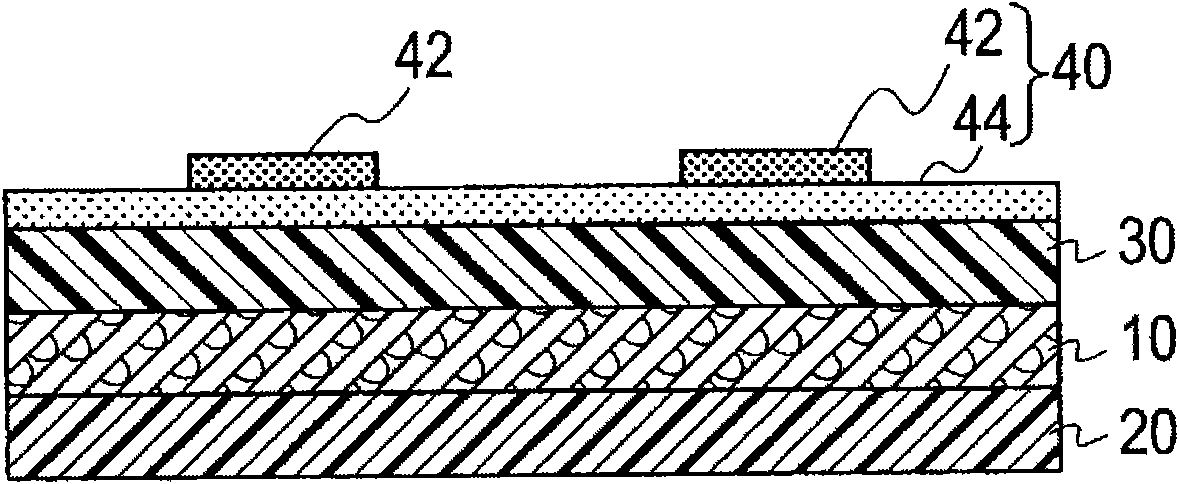

Embodiment 2~10, comparative example 1、2

[0188] Examples 2 to 10 and Comparative Example 1 were prepared in the same manner as in Example 1, except that the binder resin or binder resin mixture described in Table 2 was used instead of polyurethane resin A in Example 1. , 2 white ink and red ink. However, for the red ink of Example 9, no silica was added. In addition, with regard to Example 10, after printing the white ink of the first layer as the bottom layer on the entire surface, the white ink of the second layer is pattern-printed, and the non-printed area other than the pattern-printed part with the white ink of the second layer is further printed. red ink, thus forming a Figure 4 As an example, the printed layer (white / white and white / red) is formed in which the printed surface is composed of two layers.

[0189] Thereafter, the same operation was carried out as in Example 1, and the paper container materials with overlapping printing layers produced in Examples 2 to 10 and Comparative Examples 1 and 2 were ...

Embodiment 11

[0191] Except that 0.9 parts by weight of silicon dioxide (Sylophobic 200, (Fuji Silicon Chemical Co., Ltd., particle size 3.9 μm)) used in Example 5 was changed to silicon dioxide with a larger particle size (SYLYSIA470, Fuji Silicon Chemical Co., Ltd., particle size 14 μm) 4 weight parts, carry out the same operation as Example 5, and prepare the ink composition. Then, use the prepared ink composition, carry out the same operation as Example 1, and make a The paper container material of the printing layer was carried out in the same manner as in Example 1, and the foaming followability, foaming appearance, abrasion resistance and heat resistance of the printing layer were evaluated. The results are shown in Table 2 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com