Sputtering target of nonmagnetic-in-ferromagnetic dispersion type material

一种非磁性材料、强磁性的技术,应用在磁性膜到基材的应用、磁性层、溅射镀覆等方向,能够解决烧结温度低、靶特性改善、产生粉粒等问题,达到溅射表面光滑、延长靶寿命、减少孔隙的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1、2

[0098] (Example 1, 2, Comparative Example 1, 2)

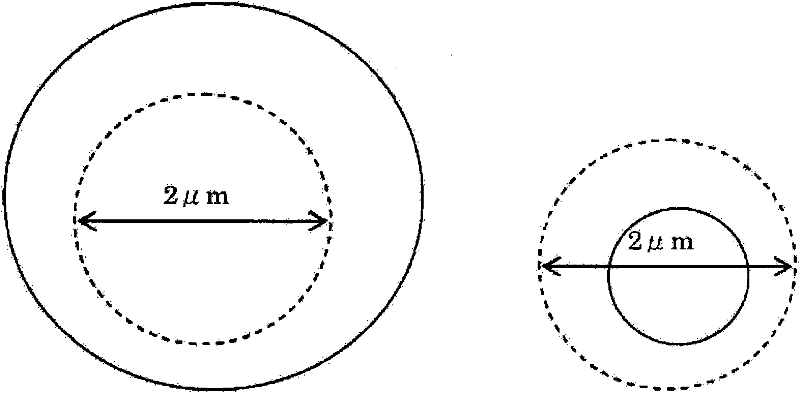

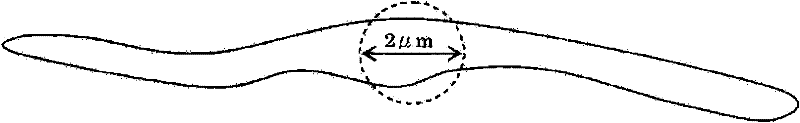

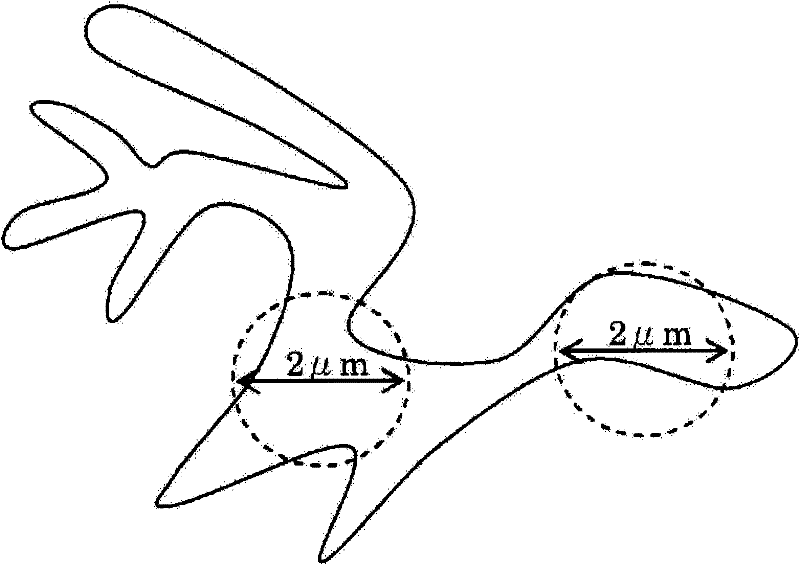

[0099] Co-Cr alloy powder and Co and silicon dioxide (SiO 2 ) powder (average particle size 1 ~ 2μm) as sintering raw material powder.

Embodiment 1

[0100] In Example 1, the Co—Cr alloy powder was 75 μm or more and less than 150 μm, and in Example 2 was 20 μm or more and less than 75 μm Co—Cr alloy powder.

[0101] In addition, in Comparative Example 1, Co—Cr alloy powder of less than 20 μm was used, and in Comparative Example 2, Cr powder of less than 20 μm was used instead of Co—Cr alloy powder.

[0102] In addition, the composition of the Co-Cr alloy powder used here contains 40 atomic % or more of Cr.

[0103] Use these powders to have a composition of 77.28Co-14.72Cr-8SiO 2 (mol %) was weighed, and this was mixed for 20 hours with a wet ball mill. Then, this mixed powder was filled into a carbon mold, and sintered by hot pressing (HP) at 1050°C for 2 hours, followed by hot isostatic pressing (HIP) to produce a sintered body, which was then machined. A disk-shaped target with a diameter of 180 mm and a thickness of 7 mm was obtained.

[0104] The relative densities of the targets obtained in this way are all above 9...

Embodiment 3

[0118] (Example 3, Comparative Example 3)

[0119] In Example 3, Co-Cr alloy powder of 75 μm to 150 μm and Co, Pt, and SiO 2 The fine powder (average particle size 1-2μm) is used as the raw material powder for sintering. In addition, in Comparative Example 3, Cr powder of less than 20 μm and Co, Pt, and SiO 2 The fine powder (average particle size 1-2μm) is used as the raw material powder for sintering.

[0120] These powders are respectively composed of 60Co-16Cr-16Pt-8SiO 2 Weigh it in the form of (mol%), mix it with a wet ball mill for 20 hours, fill the mixed powder into a carbon mold, and sinter it at 1050°C for 2 hours by hot pressing (HP), and then perform hot isostatic Press (HIP) processing to manufacture a sintered body, which was then machined to obtain a disc-shaped target with a diameter of 165.1 mm and a thickness of 7 mm. The relative densities of the targets thus obtained were all 97% or more. The results are shown in Table 2.

[0121] Table 2

[0122] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com