Microfluidic device and method

A microfluidic and microfluidic channel technology, applied in mechanical equipment, fluid controllers, chemical instruments and methods, etc., can solve the problems of high power, high inductance, consumption, etc., and achieve high frequency, low inductance, and easy penetration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

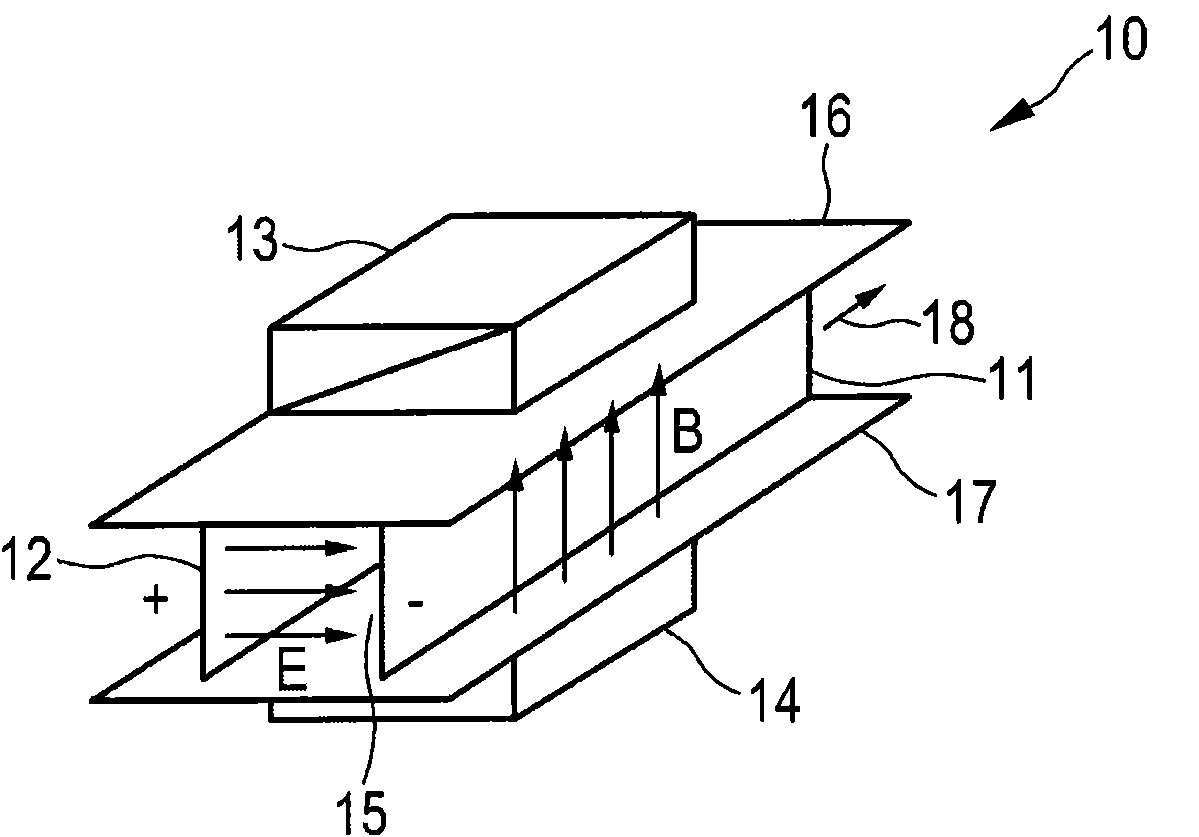

[0042] figure 1 A perspective view of a known MHD unit 10 is schematically shown, with which the magnetohydrodynamic effect will be briefly explained below. This MHD unit 10 comprises two parallel electrode plates 11, 12 for generating an electric field E and external magnets 13, 14 for generating a uniform magnetic field B perpendicular to the direction of the channel 15 formed by the parallel electrode plates 11, 12 and parallel channel plates 16, 17 arranged perpendicularly to the electrode plates 11, 12 are defined. This requires processing electrodes on both sides of the channel 15, or a combination of micromachining (deep trench etching) and photolithography to create a parallel plate configuration.

[0043] The magnetohydrodynamic effect is based on the well-known formula corresponding to the Lorentz force:

[0044] F → = e v → × B →

[0045] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com