Manufacturing method of oil bearing used at temperature over 250 DEG C

A manufacturing method and bearing technology, which is applied to other manufacturing equipment/tools, turbines, engine components, etc., can solve the problems of noise speed, incomplete filling of powder, poor product formability, etc., and achieve the effect of low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with specific examples.

[0038] A manufacturing method for oil-impregnated bearings above 250°C, the manufacturing process is powder mixing, powder pressing, high-temperature sintering, bearing precision pressing, cleaning, drying and oil immersion, wherein

[0039] The first step, powder mixing:

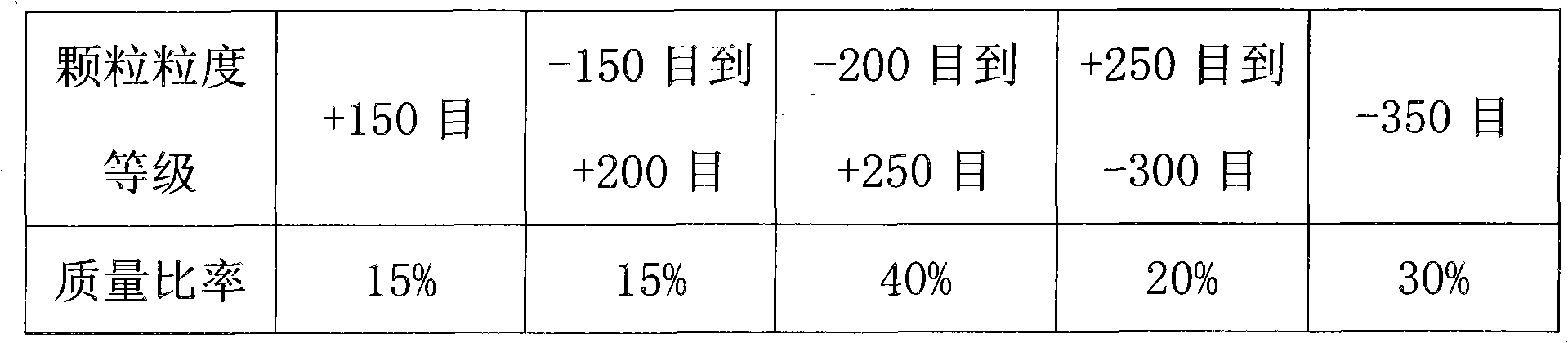

[0040] (1) Select 10 kg of atomized copper-tin alloy powder, put it into a particle size sieving machine and sieve for 30 minutes, and use a particle size of -150 order, -200 order, -300 order and -350 order sieve to sieve, after sieving, each The mass distribution of the part is:

[0041]

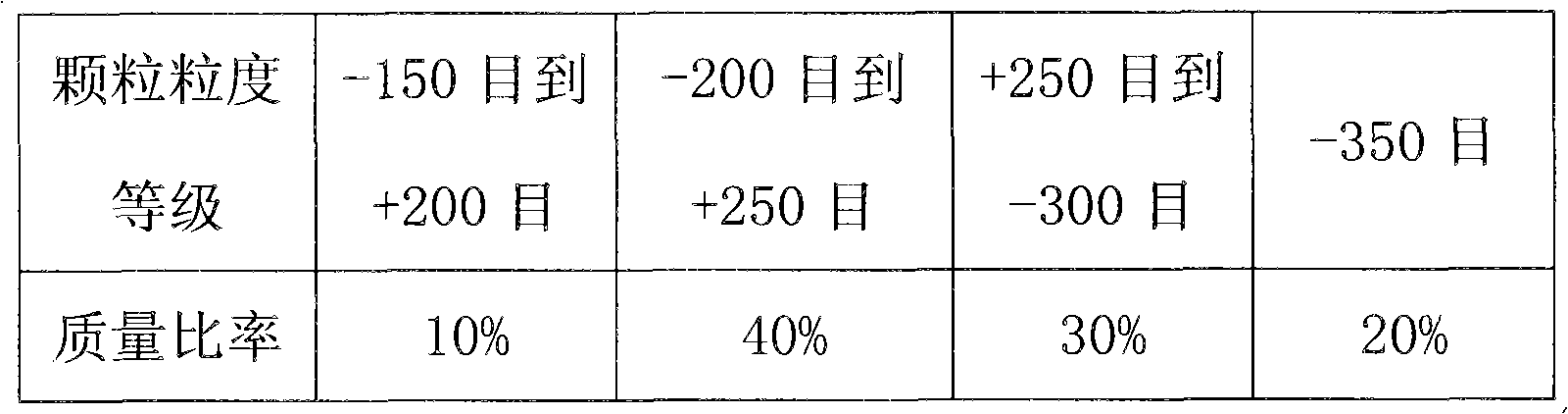

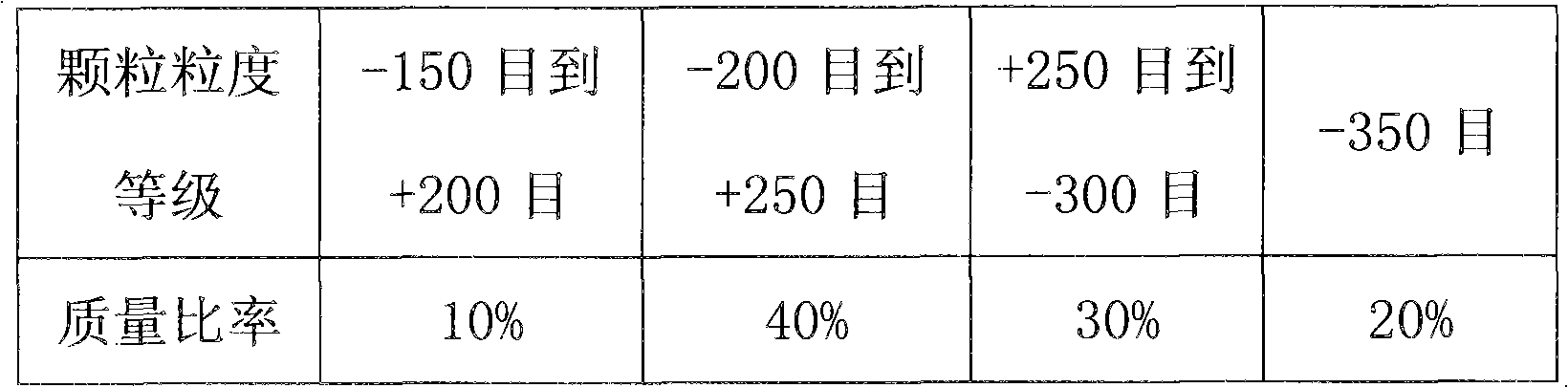

[0042] Remove the coarse powder with a particle size of -150 mesh or more, and recombine the weight of the atomized copper-tin alloy powder of each particle size to make A powder. The particle size distribution of A powder is:

[0043]

[0044] (2) Choose 10kg of atomized copper-tin alloy powder, sieve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com