Full-hydraulic multi-wheel independent-drive traction balance control system

An independent drive and balanced control technology, applied in the control device, hydraulic steering gear, transportation and packaging, etc., can solve the problems of complex control mechanism, dragging, unsuitable machinery, etc., to improve the traction efficiency and avoid the cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

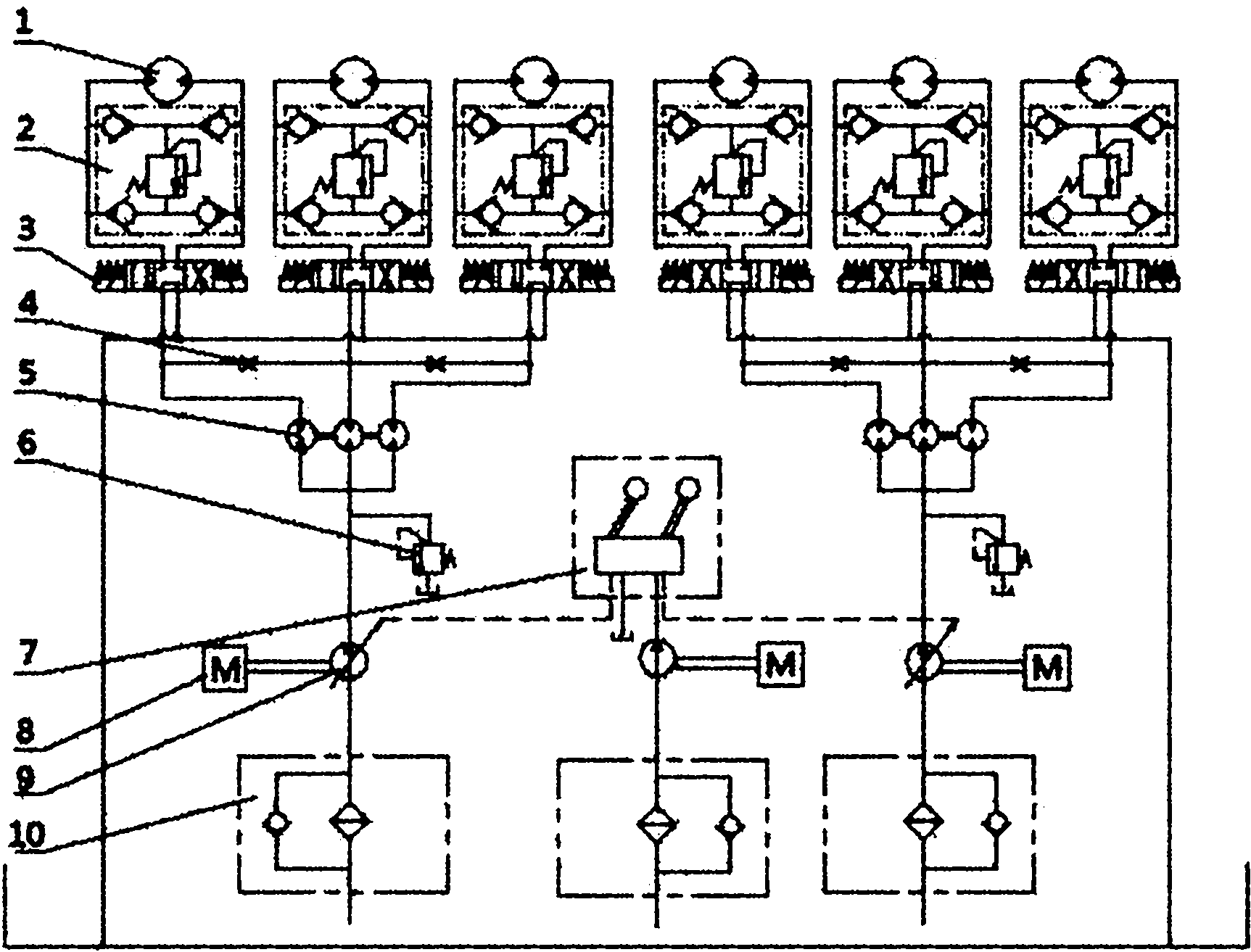

[0020] Embodiments of the present invention are described below with reference to the accompanying drawings:

[0021] figure 1 Middle: On the actual vehicle, the electromagnetic reversing valve 3, the diverter 5, the double variable plunger pump 9, the engine 8, and the manual pilot valve 7 are respectively fixed on the frame; the wheel hydraulic motor 1 is installed on the wheel hub ; Duplex variable plunger pump 9 is connected to the engine through a coupling; flow divider 5, electromagnetic reversing valve 3, wheel hydraulic motor 1, and manual pilot valve 7 are connected through hydraulic pipelines.

[0022] The double-connected plunger variable pump converts the mechanical energy provided by the engine into hydraulic energy, and the output flow of the pump is evenly distributed to the wheel side hydraulic motor through the electromagnetic reversing valve through the flow divider, and then the hydraulic energy is converted into mechanical energy through the motor, providin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com