Silicon-on-insulator waveguide grating coupler and manufacturing method thereof

A silicon-on-insulator and waveguide grating technology, which is applied in the coupling of optical waveguides, light guides, optics, etc., can solve the problems of device online testing and packaging difficulties, coupling efficiency reduction, chip performance limitations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

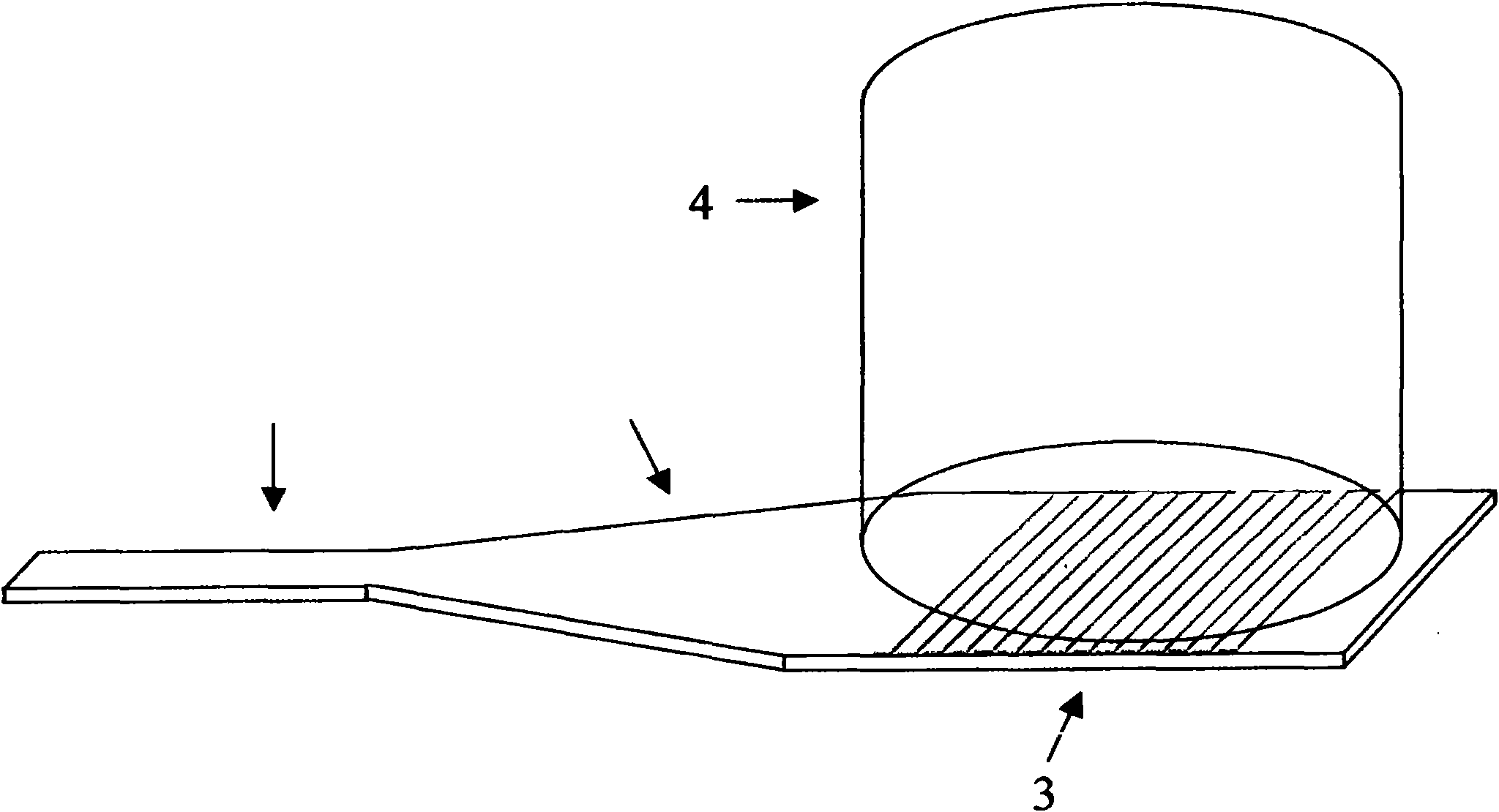

[0025] See figure 1 , figure 2 and image 3 As shown, the present invention provides a silicon-on-insulator waveguide grating coupler, the coupler adopts a silicon-on-insulator material, and includes:

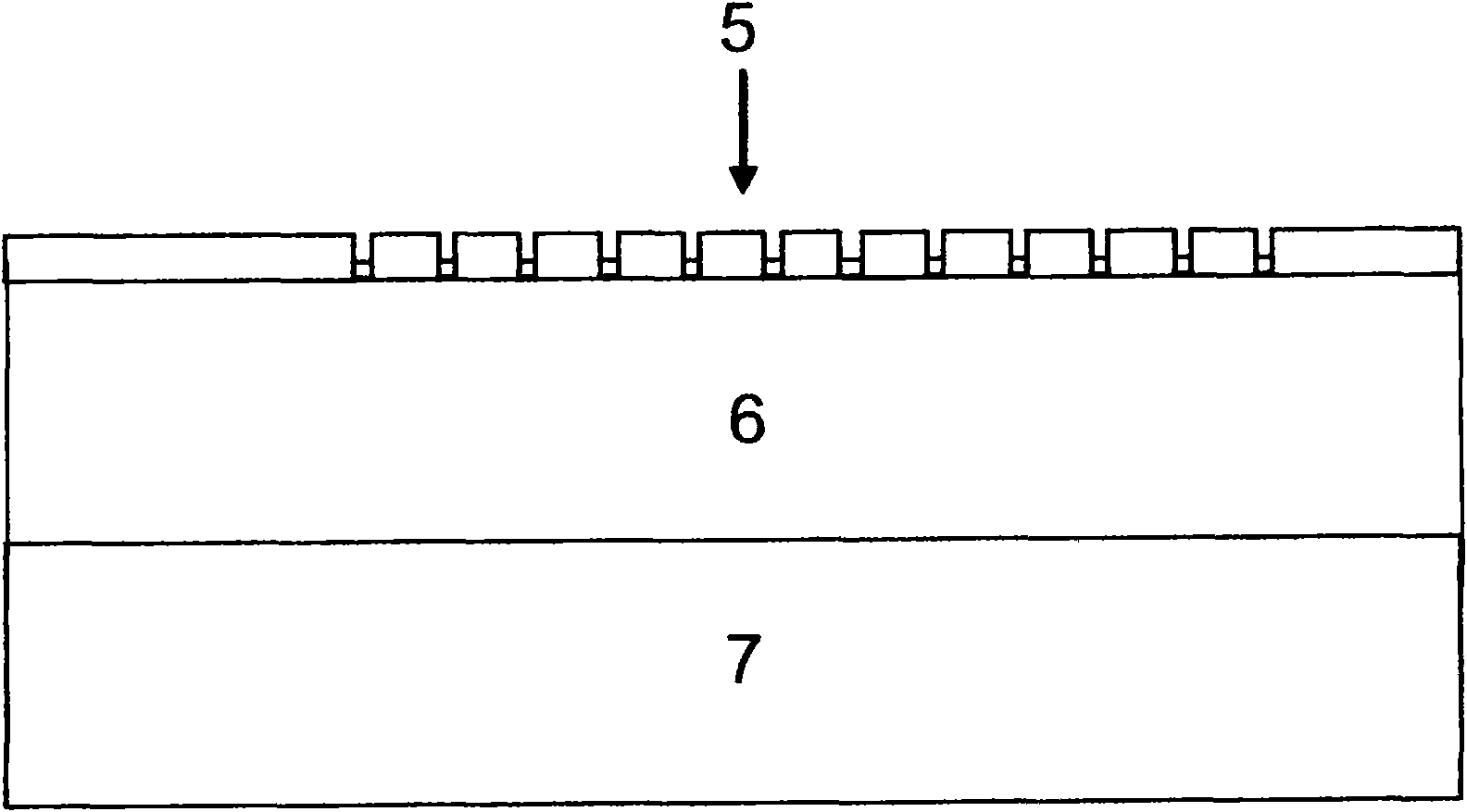

[0026] A substrate 7; the substrate is a silicon-on-insulator substrate, and the waveguide layer and the confinement layer are fabricated on the substrate.

[0027] A confinement layer 6, the confinement layer 6 is made on the substrate 7; the thickness of the confinement layer 6 is greater than 1 μm; the confinement layer is a silicon-on-insulator confinement layer, because its refractive index is smaller than the waveguide layer, it can confine light in the waveguide layer In the waveguide

[0028] A waveguide layer 5, the waveguide layer 5 is fabricated on the confinement layer 6, a diffraction grating 3 is fabricated laterally on one end of the waveguide layer 5, the thickness of the waveguide layer 5 is less than 1 μm; the waveguide layer 5 includes: submicron waveguide 1, Tape...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com