Pole shoes of rechargeable battery and manufacturing method thereof

A technology for battery pole pieces and rechargeable batteries, applied to battery electrodes, non-aqueous electrolyte battery electrodes, lead-acid battery electrodes, etc. problem, to achieve the effect of reducing the effective volume, reducing the battery micro-short circuit and safety hazards, and reducing the dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

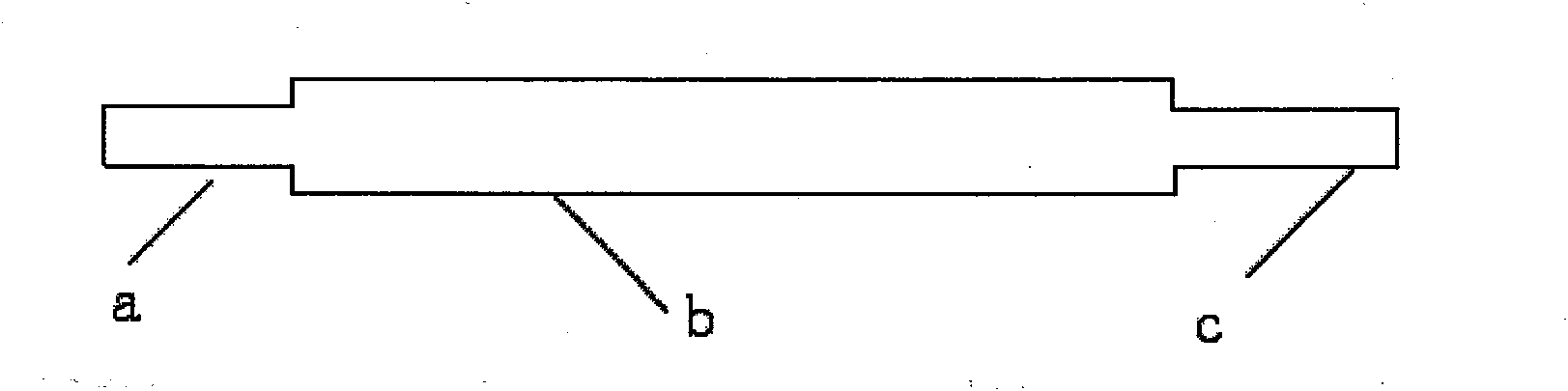

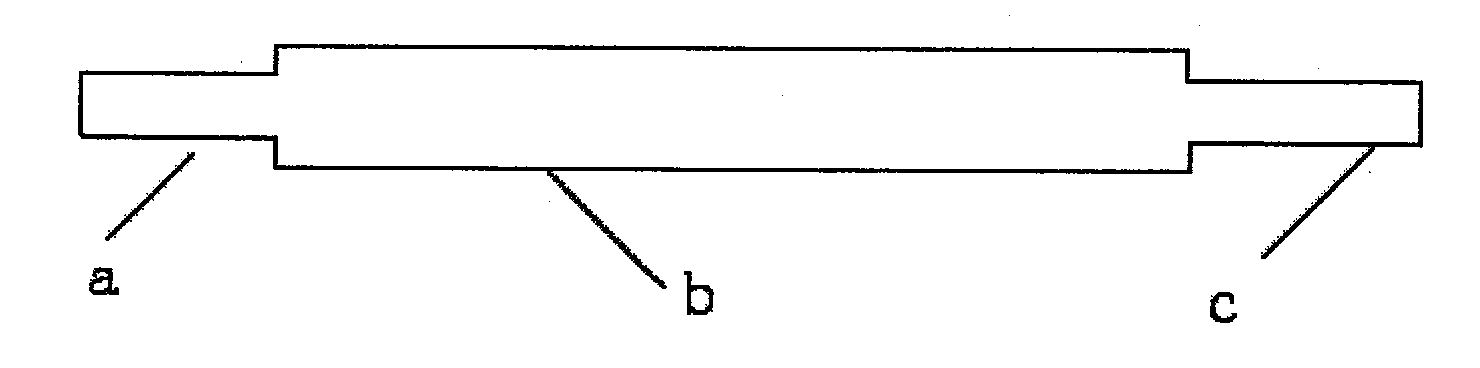

[0024]Battery positive electrode: Commercially available spherical nickel hydroxide and cobaltous oxide powder are fully mixed in a ratio of 94:6 according to mechanical methods to form a positive electrode mixed powder; commercially available continuous strip-shaped nickel foam with a width of 90mm and a thickness of 1.6mm, It is pre-pressed into a thickness of 1.3mm by a pair of cylindrical pressure rollers with a uniform gap; the above-mentioned foamed nickel is then pre-pressed into a specified thickness and length by two pairs of rollers on both sides of the edge, that is, the head and tail. The length is 4.5mm, the thickness is 1.1mm, the length of the tail is 9mm, the thickness is 1.1mm, the length of the middle part is 76.5mm, and the thickness is 1.3mm; pour the mixed powder into the upper powder box containing 2 pairs of electric brushes arranged up and down, Pass the pre-compressed nickel foam belt from the bottom of the powder box through the middle of the two pairs...

Embodiment 2

[0029] Battery positive electrode: the positive electrode manufacturing process is basically the same as in Example 1, the difference is that the length of the positive electrode piece is controlled to change the length of the head of the positive electrode piece, thereby controlling the filling amount of the mixed powder at the head piece of the electrode piece, and a battery with the characteristics described in the present invention is manufactured. The electrode piece P2 is 6.8mm long, accounting for 7.5% of the total length of the pole piece, and 0.50mm thick, accounting for 70% of the pole piece thickness; the tail is 13.5mm long, accounting for 15% of the total length of the pole piece, and 0.50mm thick, accounting for 70% of the pole piece thickness. %; the middle length is 72.0mm, accounting for 77.5% of the total length of the pole piece, and the thickness is 0.71mm. Each electrode contains mixed powder: 7.82-7.84g.

[0030] Battery negative electrode: take the negat...

Embodiment 3

[0034] Battery positive electrode: the positive electrode manufacturing process is basically the same as in Example 1, except that the length of the roller is controlled to change the length of the tail of the positive electrode, thereby controlling the filling amount of the mixed powder at the tail of the electrode, and an electrode with the characteristics described in the present invention is produced Piece P3, the length of the head is 9.0mm, accounting for 10% of the total length of the pole piece, the thickness is 0.36mm, accounting for 50% of the thickness of the pole piece; the length of the tail is 18.0mm, accounting for 20% of the total length of the pole piece, and the thickness is 0.36mm, accounting for 50% of the thickness of the pole piece; The middle length is 63.0mm, accounting for 70% of the total length of the pole piece, and the thickness is 0.71mm. Each piece of electrode contains 7.21-7.23g of mixed powder.

[0035] Battery negative electrode: take the nega...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com