Method for preparing rare earth-doped yttrium aluminum garnet transparent ceramic

A technology of yttrium aluminum garnet and transparent ceramics, which is applied in the field of preparation of rare earth-doped yttrium aluminum garnet transparent ceramics, which can solve the problems of serious powder agglomeration, unfavorable molding, and poor powder fluidity, and achieve high linear transmittance , good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

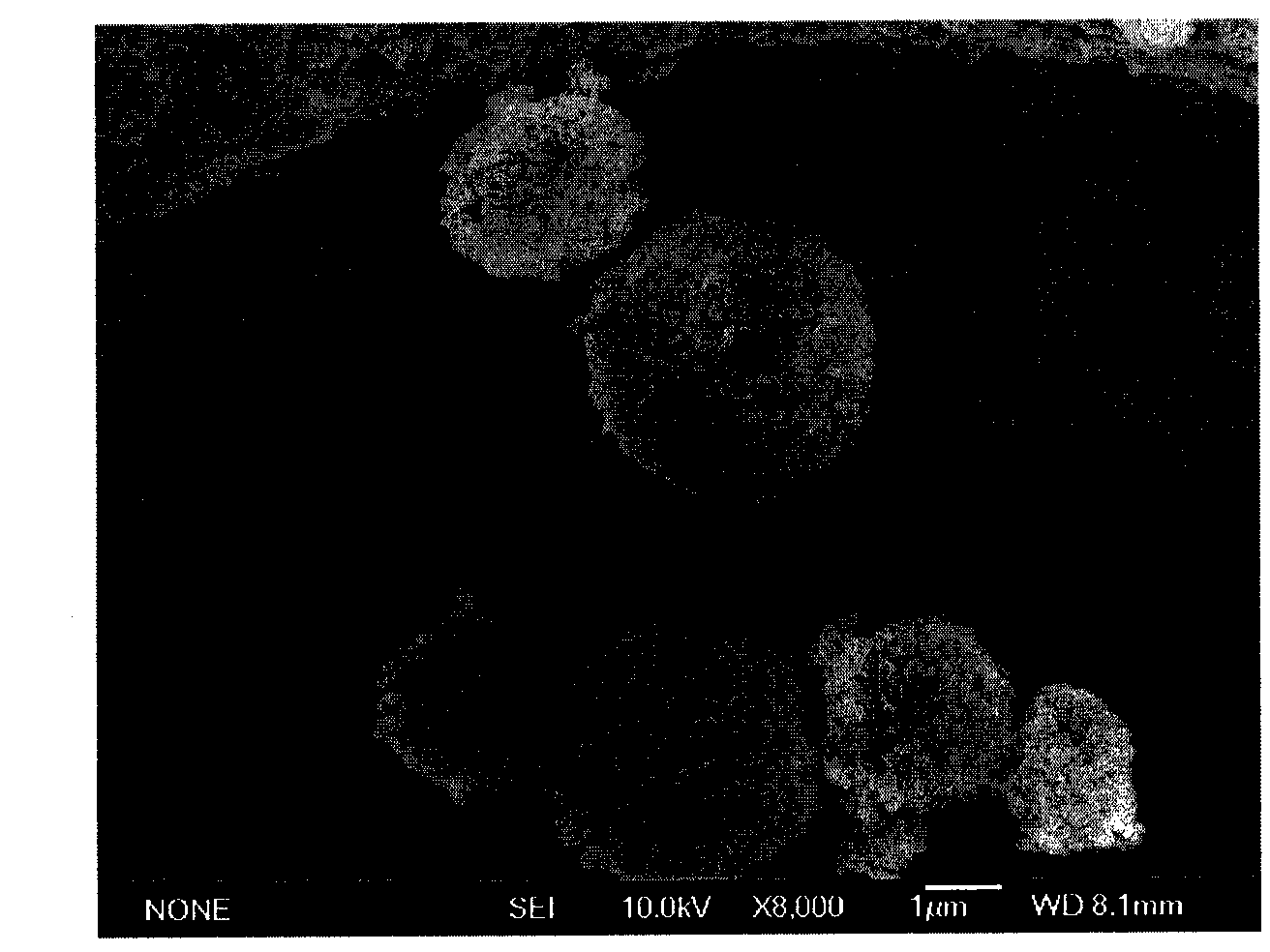

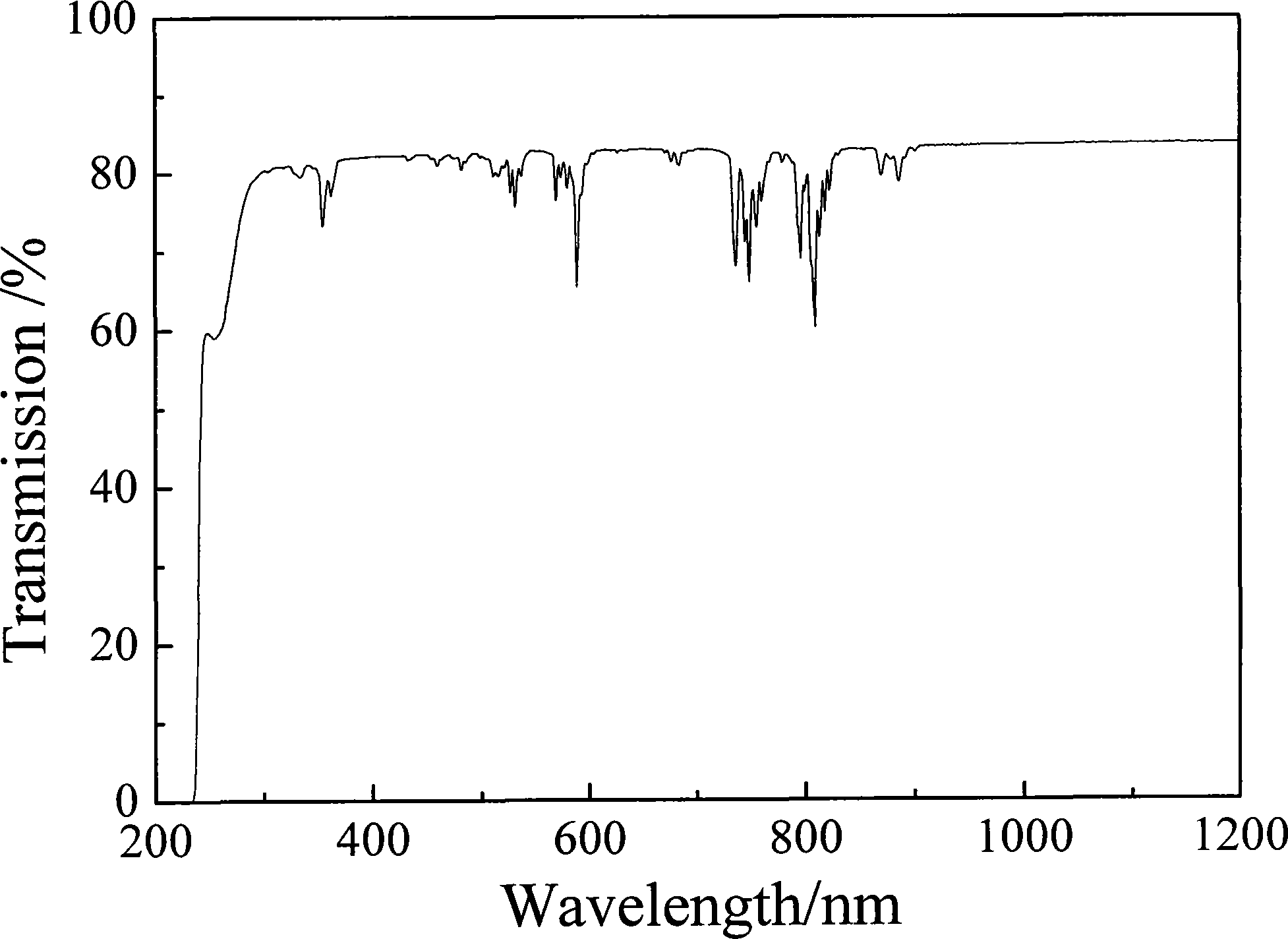

[0027] Put 5.098g of α-Al2O3 powder, 6.7066g of Y2O3 powder, 0.1010g of Nd2O3, 0.0600g of TEOS and 0.3600g of PVB into a high-purity agate ball mill jar, add 72g of high-purity agate balls, anhydrous Ethanol 6g, then ball milled for 20h. After ball milling, the slurry was spray-dried, the inlet temperature was 110° C., the spray gas flow rate was 400 Nor mlitre / h, and the feed rate was 6 ml / min. Axial one-way pressurization with a pressure of 10Mpa, pressed into a disc of Φ15, and then cold isostatic pressing under a pressure of 200Mpa. The degreased green body was sintered in a vacuum furnace, the heating rate of the furnace was 10°C / min, the final sintering temperature was 1835°C, and the sintering time was 15h. Finally, the ceramics were ground and polished to a thickness of 1.50 mm with a surface grinder and diamond paste. The photo of the polished 1at%Nd:YAG ceramic 1.50mm piece is shown in figure 2 , and its transmittance curve is shown in image 3 . At the laser w...

Embodiment 2

[0029] Put 5.098g of α-Al2O3 powder, 6.7066g of Y2O3 powder, 0.1010g of Nd2O3, 0.0600g of TEOS, 0.3600g of PVB and 0.0060g of castor oil into a high-purity agate ball mill jar, other processes and implementation Example 1 is the same. The degreased green body was sintered in a vacuum furnace with a heating rate of 10°C / min, pre-sintering at 1500°C for 5 hours, final sintering temperature of 1820°C, and sintering time of 10 hours. Finally, the ceramics were ground and polished to 1.00 mm thickness with a surface grinder and diamond paste. The linear transmittance of the sample at the laser wavelength (1064nm) is 83%.

Embodiment 3

[0031] Put 5.098g of α-Al2O3 powder, 6.7066g of Y2O3 powder, 0.1010g of Nd2O3, 0.0600g of TEOS, 0.3000g of PVB and 0.0060g of castor oil into a high-purity agate ball mill jar, other processes and implementation Example 1 is the same. The degreased green body was sintered in a vacuum furnace. The heating rate of the furnace was 10°C / min, the final sintering temperature was 1830°C, and the sintering time was 40h. Finally, the ceramics were ground and polished to a thickness of 3.00 mm with a surface grinder and diamond paste. The linear transmittance of the sample at the laser wavelength (1064nm) is 81%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com