Method for separating lisinopril ester

A separation method and a technology of primate, which are applied in the field of process-strengthening extraction technology to separate medicines or intermediates, can solve the problems of many extraction times, high extraction energy consumption, complicated operations, etc., and achieve high extraction rate, low solvent consumption, The effect of three wastes and less energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

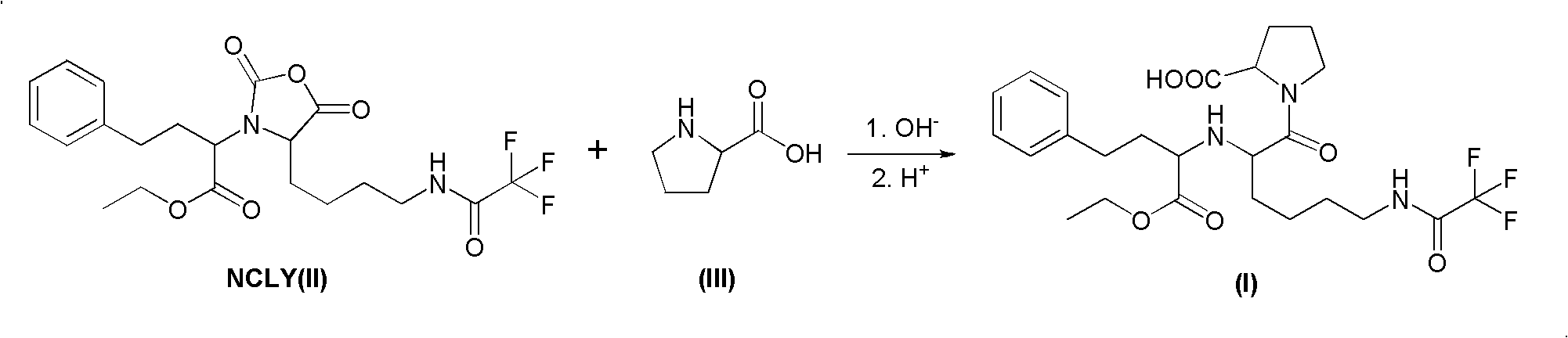

Method used

Image

Examples

Embodiment 1

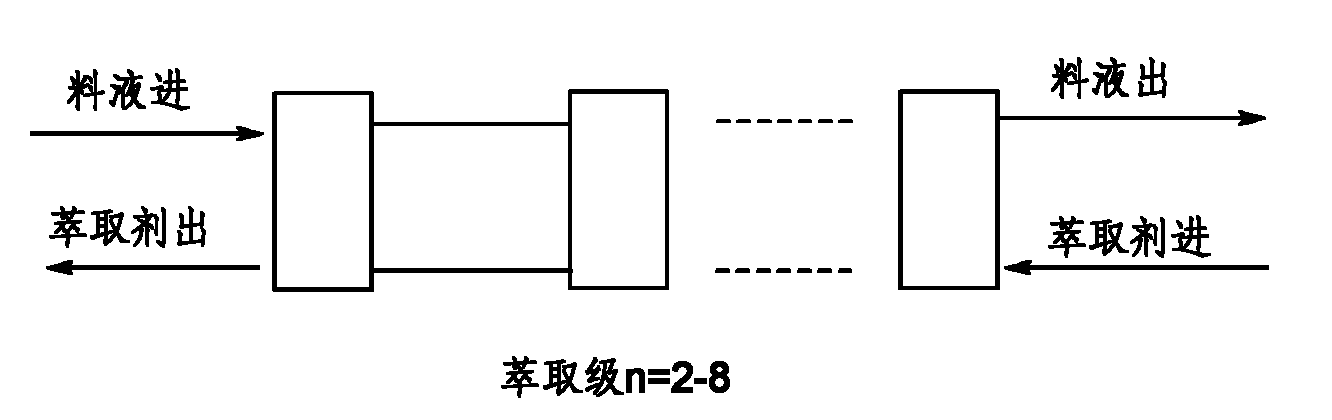

[0029] With the feed liquid containing lisinopril ester (15%, mass content, liquid chromatography detection), take ethyl acetate as extraction agent, operating temperature is 25 ℃, extraction equipment is D20 centrifugal extractor, and rotating speed is 3000 rpm Min, the volumetric flow rate V of the operating flow ratio of the extractant 1 / Volume flow rate of feed liquid V 2 =0.5 / 1.0, the total flow rate of extractant and feed liquid is 40mL / min, extraction stage 5 (5 sets of D20 centrifugal extractors connected in series), carry out centrifugal extraction, extract phase is through concentrating and reclaiming organic solvent, obtains lisinopril ester , the extraction rate was 91.0%, and the lisinopril purity was 95.2% (detected by liquid chromatography).

Embodiment 2

[0031] With the feed liquid that contains lisinopril ester (15%, mass content), take cyclohexane as extraction agent, operating temperature is 40 ℃, and extraction equipment is D20 centrifugal extractor, and rotating speed is 5000 revs / min, operating flow ratio The volumetric flow rate V of the extractant 1 / Volume flow rate of feed liquid V 2 =1.0 / 1.0, the total flow rate of extractant and feed liquid is 40mL / min, extraction stage 3 (3 sets of D20 centrifugal extractors connected in series), carry out centrifugal extraction, extract phase is through concentrating and reclaiming organic solvent, obtains lisinopril ester , the extraction rate is 93.3%, and the purity of lisinopril is 94.3%.

Embodiment 3

[0033] With the feed liquid that contains lisinopril ester (15%, mass content), take cyclohexane as extraction agent, operating temperature is 25 ℃, and extraction equipment is D20 centrifugal extractor, and rotating speed is 5000 rev / mins, and operating flow ratio The volumetric flow rate V of the extractant 1 / Volume flow rate of feed liquid V 2 =2.0 / 1.0, the total flow rate of extractant and feed liquid is 40mL / min, extraction stage 2 (2 sets of D20 centrifugal extractors connected in series), carry out centrifugal extraction, the organic solvent is reclaimed through concentration of extraction phase, obtains lisinopril ester , the extraction rate is 89.6%, and the purity of lisinopril is 93.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com