High pressure water jet cutting drum coal dropping double power shearer

A high-pressure water jet and shearer technology, which is applied to cutting machinery, earthwork drilling, cutting machinery, etc., to achieve the effects of low device investment, high efficiency and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

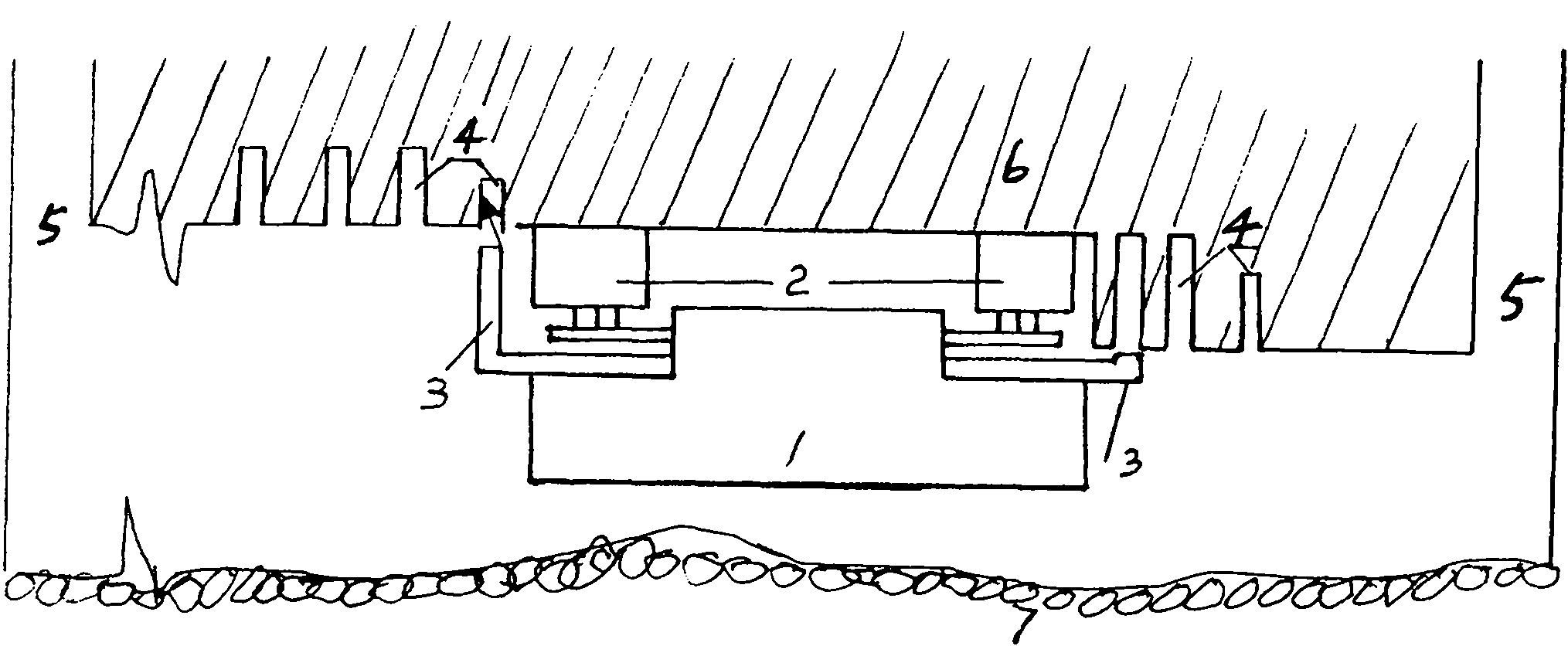

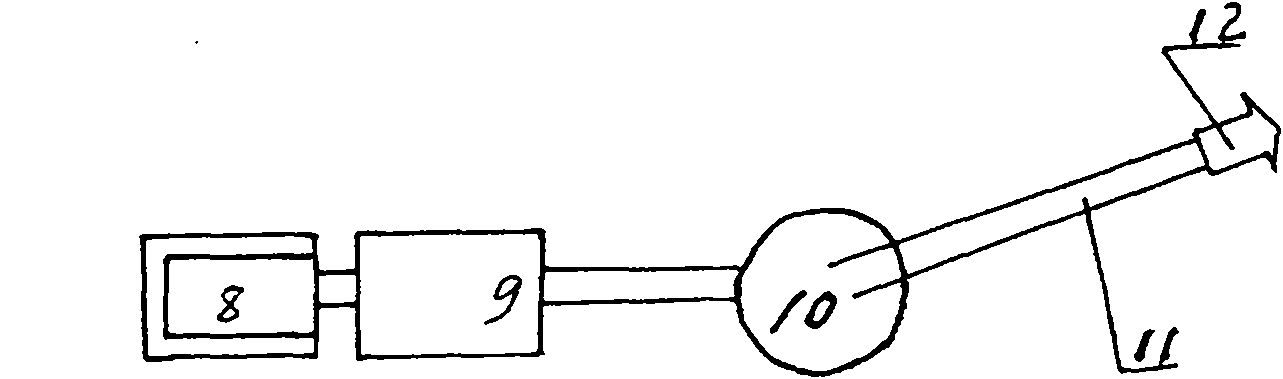

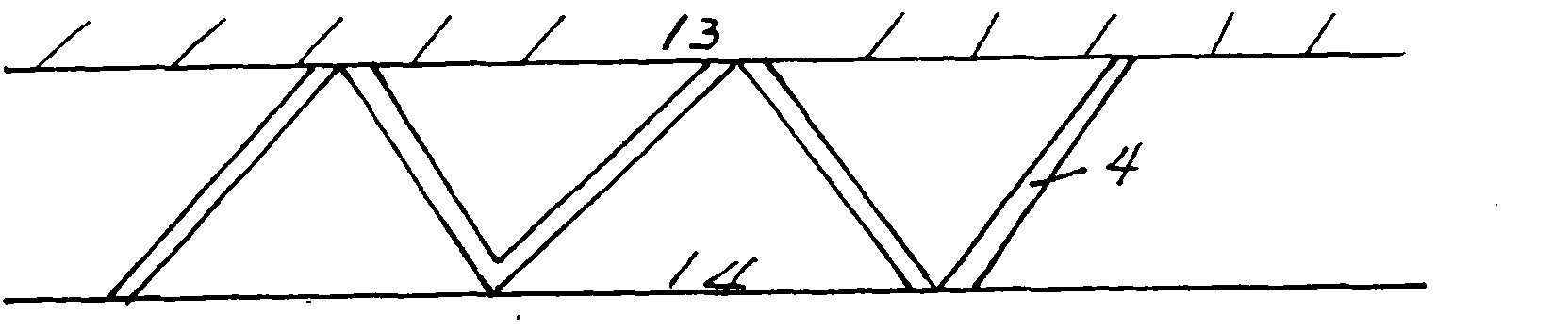

Embodiment 1

[0022] The high-pressure water jet slit drum coal-dropping dual-power shearer provided by the present invention includes MG2X300-W double-drum shearer 1 (produced and sold by Jixi Coal Mine Machinery Factory), and its parameters are: machine surface height 1600mm, mining range 2.0 ~3.7m, inclination ≤35℃, Platinum hardness ≤3f, traction force 400KN, main oil pump working flow 275L and working pressure 16MPa; hydraulic motor rated torque 1300 and working speed 88.26r / min; cutting mechanism: drum diameter 1600 -2000mm, cutting depth 630mm, maximum cutting torque 83000 (N, M), rocker arm rotation center moment 6200mm, drum speed 25-45.6 (r / min), undercover capacity 135-335 (mm); supporting motor: power 2×300KW, voltage 1140V, speed 1472r / min; cable ucPQ3×70+1×16+3×6; set internal and external spraying, the volume is 44 tons, high-pressure water jet slotting device 3 including high-pressure water pump 9 is 1400kg / cm 2 , volume: length × width × height = 1.75 × 0.75 × 0.6m, motor 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com