Control method of detonation pipe for high-frequency pulse detonation engine

A technology of detonation engine and high-frequency pulse, which is applied in the direction of engine components, fuel control of turbine/propulsion device, mechanical equipment, etc. The working needs of the vibration engine and other issues can be achieved to achieve the effect of extending the life, reducing the load, and reducing the response frequency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

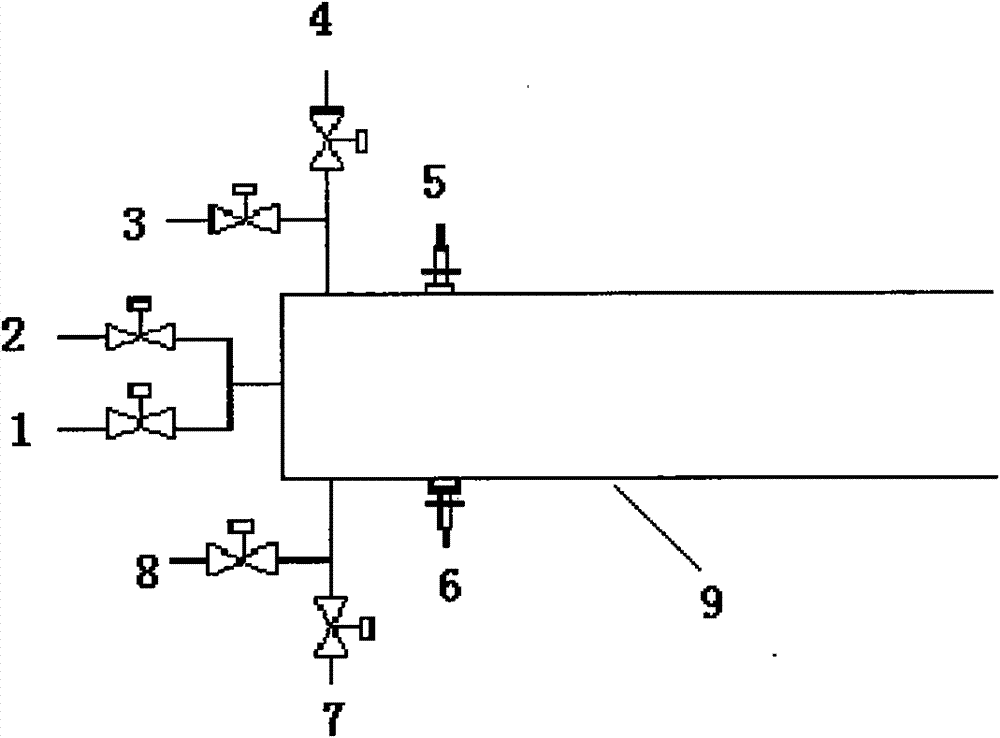

[0027] Refer to attached figure 1 , the detonation tube 9 of a high-frequency pulse detonation engine is connected with a first fuel inlet electromagnetic valve 1 and a second fuel inlet electromagnetic valve 2 at the fuel inlet of the detonation tube 9, and at the isolation gas inlet The first isolation gas inlet electromagnetic valve 3 and the second isolation gas inlet electromagnetic valve 4 are connected, the first oxidant inlet electromagnetic valve 7 and the second oxidant inlet electromagnetic valve 8 are connected at the oxidant inlet, and the detonation tube 9 is also connected A first igniter 5 and a second igniter 6 are horizontally oppositely installed on the detonation tube. The oxidizer inlet and the isolation gas inlet of the detonation tube 9 are relatively installed, and both are located in the middle of the igniter and the closed end of the detonation tube. The center of the closed end of the shock tube is axially air-intaked.

[0028] In this embodiment,...

Embodiment 2

[0035] The difference between the structure of the detonation tube 9 and that of Embodiment 1 is that the distance between the oxidant inlet and the isolation gas inlet and the closed end of the detonation tube is 1 times the inner diameter of the detonation tube; the distance between the spark plug and the closed end of the detonation tube 9 is 90 mm, that is, the detonation 3 times the inner diameter of the tube.

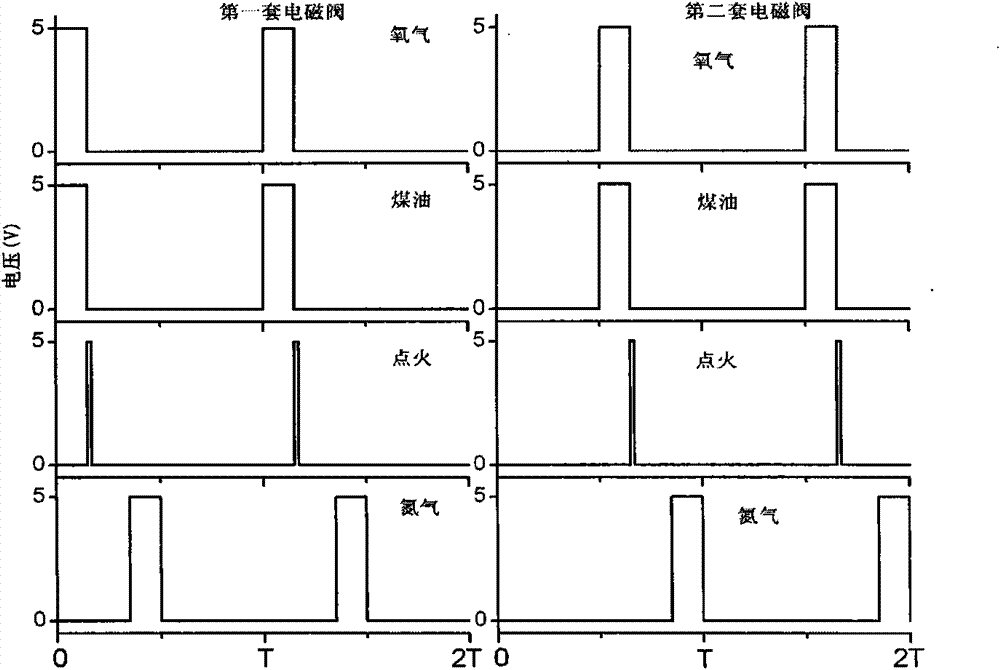

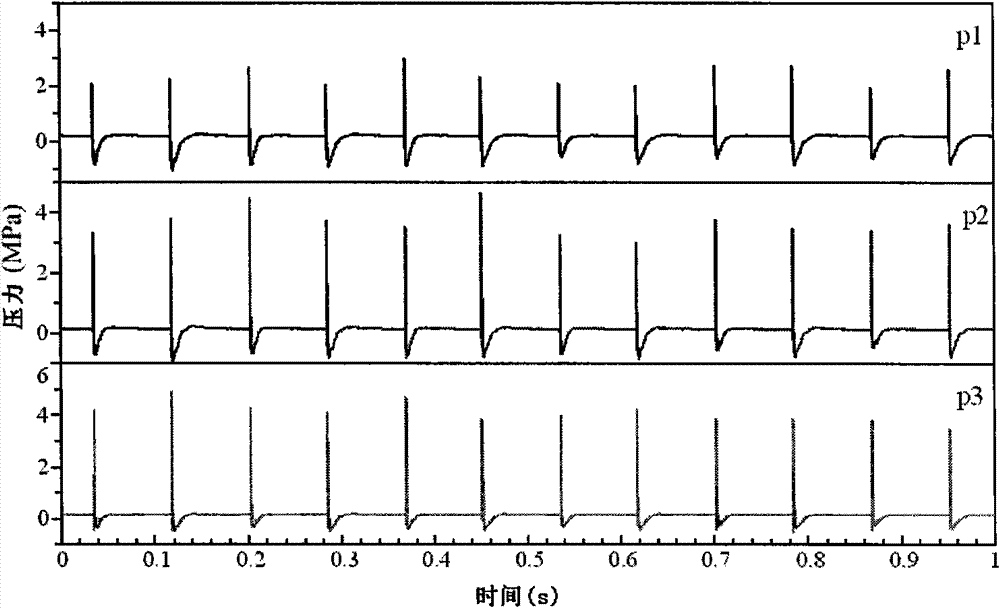

[0036] This embodiment is tested on a pulse detonation engine, and the control system outputs eight square wave signals to control two sets of solenoid valves and two igniters. In the first half of a control cycle, the first fuel inlet solenoid valve 1, the first oxidant inlet solenoid valve 7, the first igniter 5 and the first isolation gas inlet solenoid valve 3 work, and the first fuel inlet solenoid valve 1 And the duty cycle of the first oxidant inlet solenoid valve 7 is 0.3, the phase is 0°, the duty cycle of the first igniter 5 is 0.04, the phase is 108°, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com