Pixel driving circuit for active organic light-emitting diode (OLED) display and driving method thereof

A pixel driving circuit and light emitting diode technology, applied in static indicators, instruments, etc., can solve the problems that the threshold voltage cannot achieve uniform display, the peripheral driver chip is difficult to achieve, and the threshold voltage compensation effect is affected, and the number of The effect of improving pixel aperture ratio and saving wiring space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

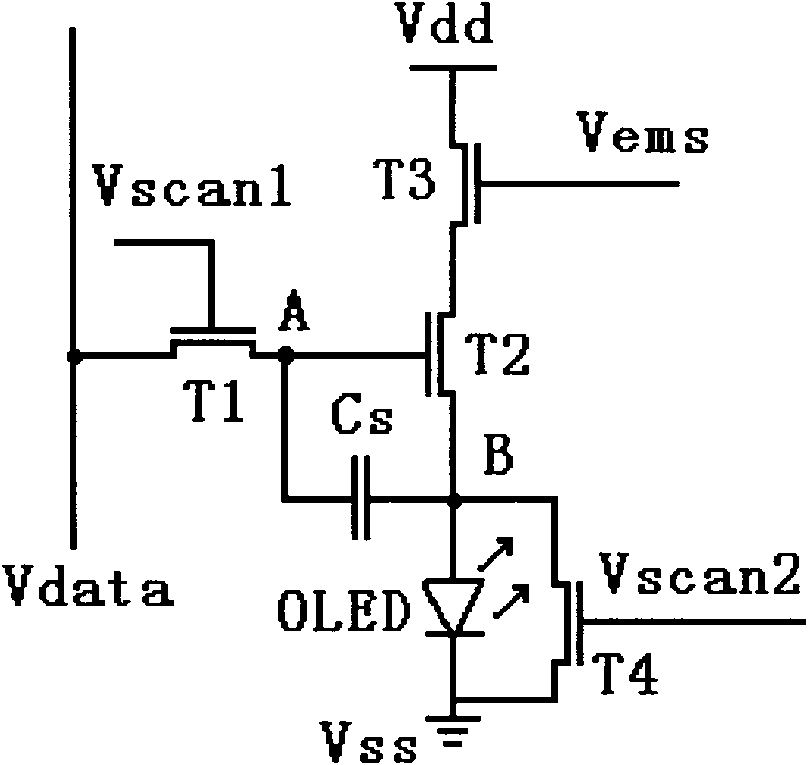

[0026] Such as image 3As shown, the active organic light emitting diode display pixel driving circuit of the present invention includes a first transistor T1, a second transistor T2, a third transistor T3, a fourth transistor T4, a storage capacitor Cs, a first scanning control line Vscan1, a second scanning A control line Vscan2, a light-emitting control line Vems, a power line Vdd, a ground line Vss, a data line Vdata, and an organic light-emitting diode OLED. The aforementioned transistors may be any one of polysilicon thin film transistors, amorphous silicon thin film transistors, zinc oxide-based thin film transistors or organic thin film transistors.

[0027] The drain of the first transistor T1 is connected to the data line Vdata, the gate is connected to the first scanning control line Vscan1, and the source is connected to the A terminal of the storage capacitor Cs, and the first transistor T1 is used for writing the data voltage into the second transistor T2 The ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com