High-performance double sunlight greenhouse for four seasons

A solar greenhouse, dual-type technology, which is applied in the field of high-performance dual-type solar greenhouses for four seasons, can solve the problems of icing of the outer shed film, vegetables that need to be insulated and shaded, and reduced thermal insulation performance. Inner temperature, saving labor resources, and improving the effect of thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

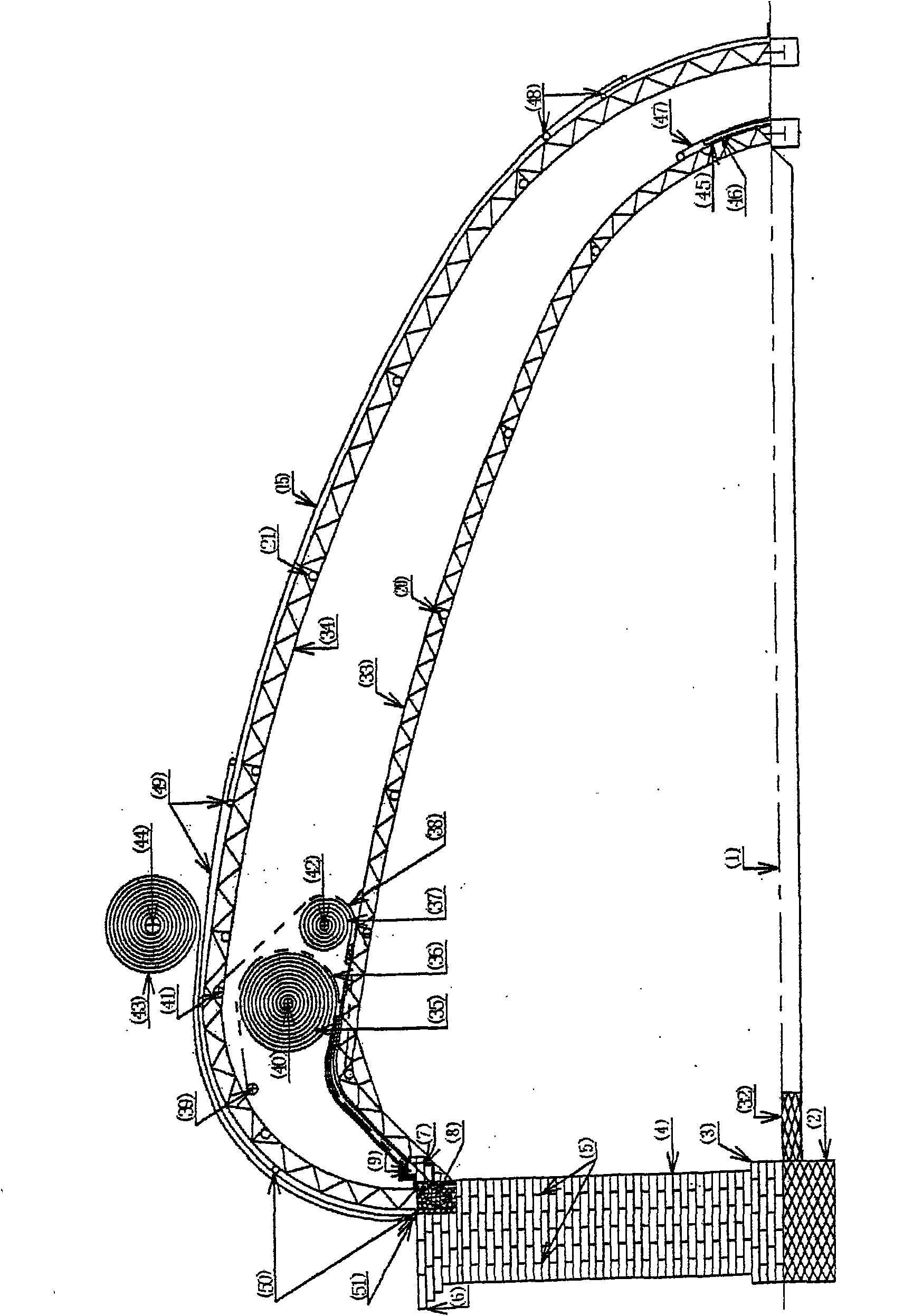

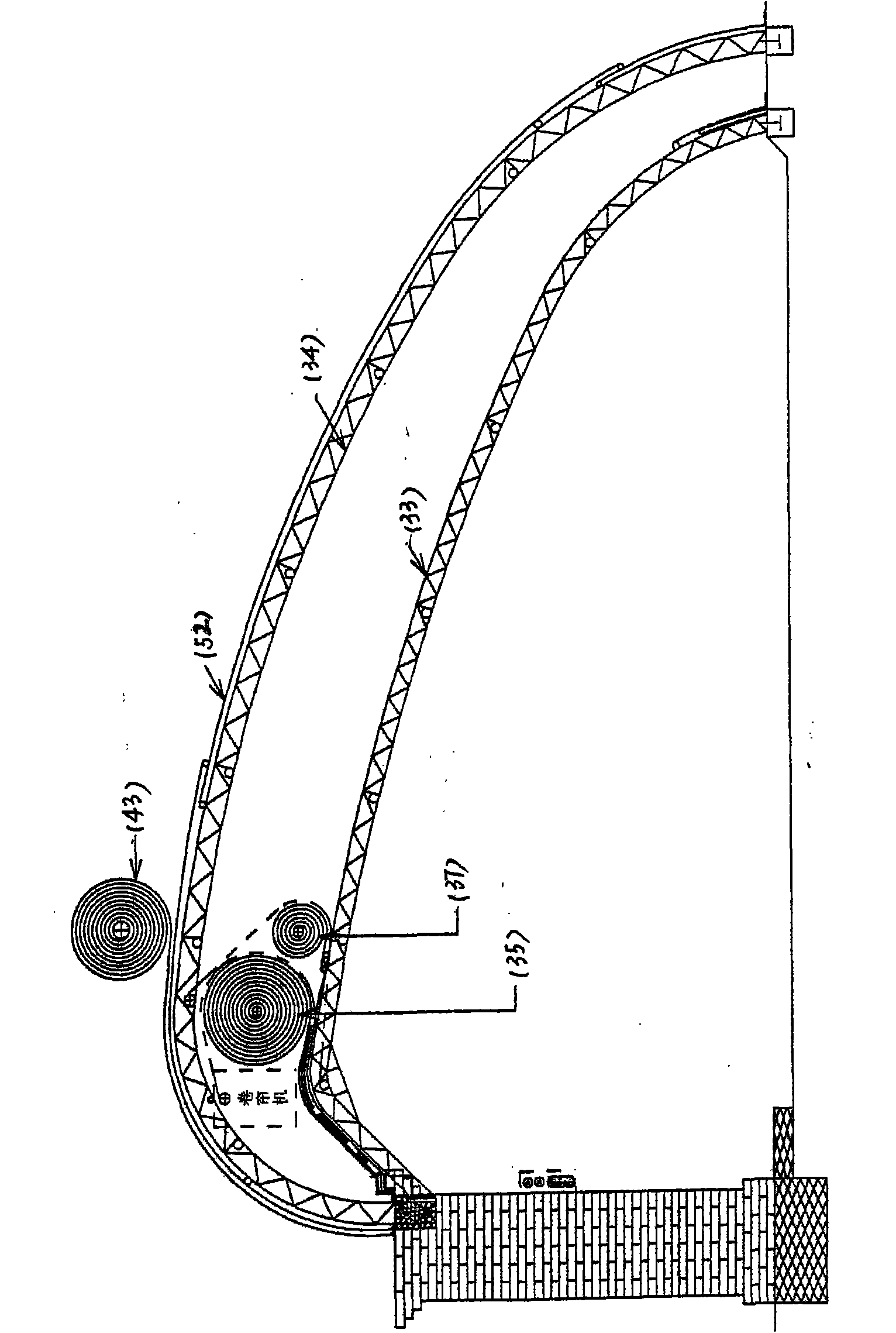

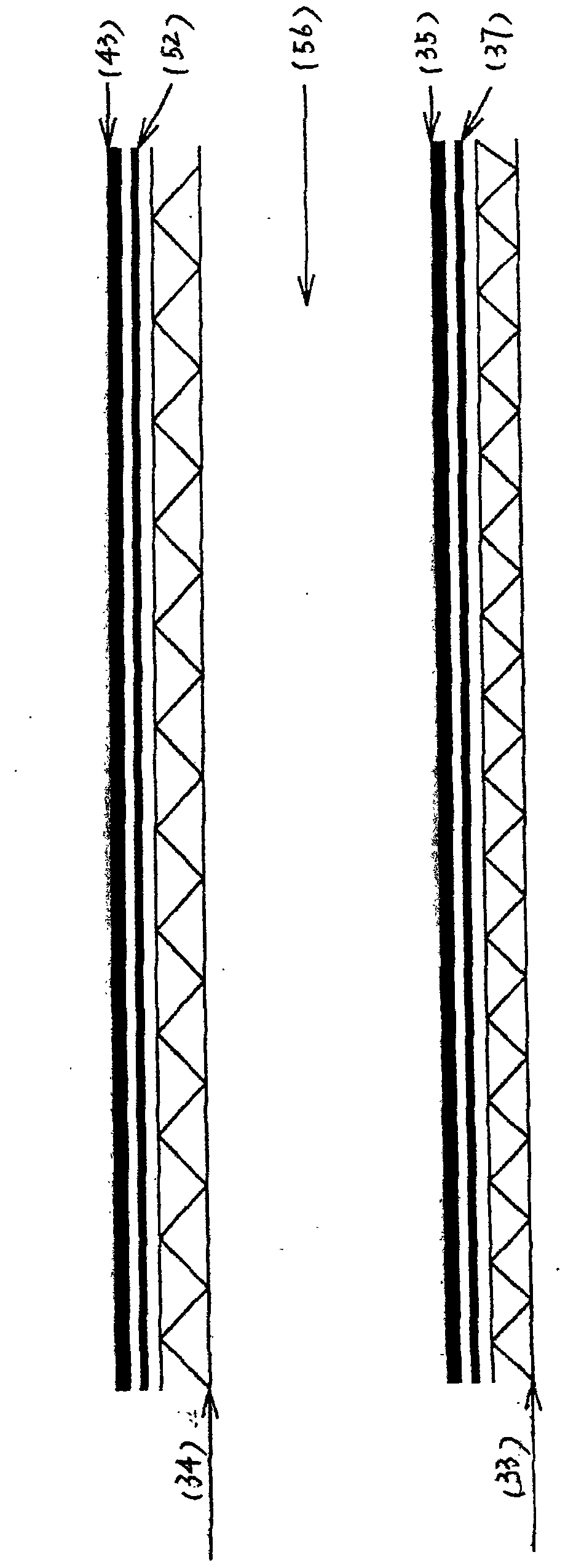

[0037] Such as figure 1 , 2 Shown in , 3: a high-performance double-mounted solar greenhouse for four seasons, fixedly installed on the ground plane 1 and the wall, consisting of inner and outer sheds, the inner shed is covered with an inner shed film, and the inner shed The film is covered with an inner layer of insulation quilt, the outer layer of scaffolding is covered with an outer layer of shed film, the outer layer of shed film is covered with an outer layer of insulation quilt, an air insulation layer is formed between the inner and outer layer scaffolding, and the inner layer of insulation The distance between the quilt and the outer shed film is greater than 0.5 meters. The inner insulation is wound on the inner rolling machine, the inner shed film is wound on the inner rolling machine, and the outer insulation is wound on the outer rolling machine.

[0038] Such as Figure 4 As shown: the above-mentioned inner layer roller blind machine adopts a worm gear reducer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com