Method for testing service life of rolling bearings

A technology of rolling bearings and test methods, which is applied in the direction of mechanical bearing testing, etc., can solve the problems of complex test process and damage, and achieve the effect of simple test method, cost reduction and shortening aging cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

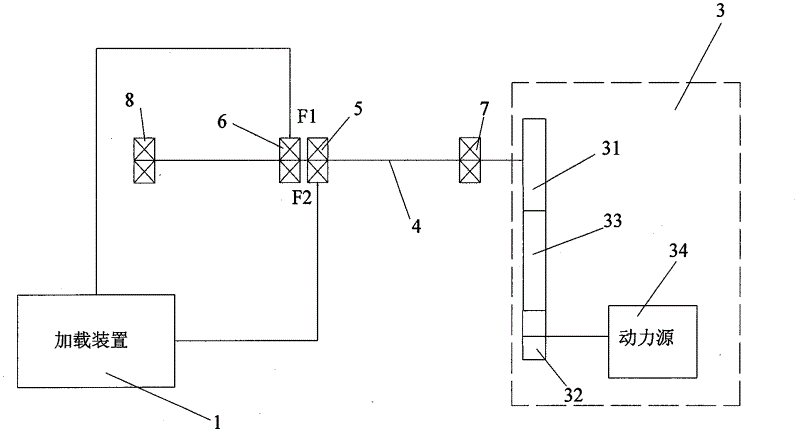

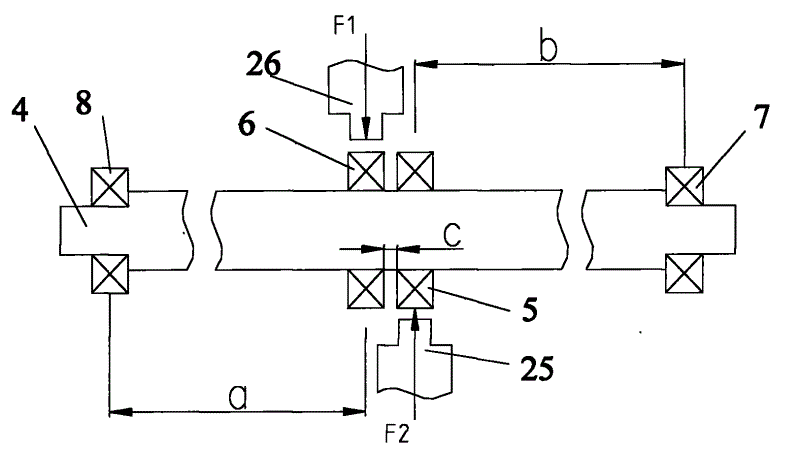

[0020] Such as figure 2 As shown, the test system of the rolling bearing life test of the present invention includes an optical axis 4, a power transmission device 3 and a loading device 1. The power transmission device 3 is connected to the optical axis 4 and can drive the optical axis 4 to rotate. The optical axis 4 is used to install two For the rolling bearings 5 and 6 to be tested, a pair of loads of equal magnitude and opposite directions along the radial direction of the optical axis shall be applied to the two rolling bearings 5 and 6 to be tested during the test.

[0021] Power transmission device 3 is provided with first belt pulley 32, power source 34, second belt pulley 31 and belt 33, and power source 34 can be the device that provides power, as motor, motor etc., and second belt pulley 31 is fixedly connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com