Method for measuring silicon dioxide content in solution

A silicon dioxide and determination method technology, applied in the field of chemical detection, can solve problems such as difficult storage, complicated preparation methods, inconvenient use, etc., and achieve the effect of eliminating interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0062] This embodiment takes the determination of the silicon dioxide content in the chromic acid anodizing sealing solution as an example.

[0063] The chromic acid anodizing sealing solution is prepared with deionized water to prepare chromic acid with a nominal concentration of 26 g / 100 gallon (about 70 ppm) and 18 g / 100 gallon of sodium chromate or 26 g / 100 gallon of magnesium chromate solution Or a 22 g / 100 gal potassium chromate solution.

[0064] In general, for closed cells for chromic acid anodization, maintain the solution with the following parameters:

[0065] Hexavalent chromium 45~100ppm (based on Cr 6+ count)

[0066] PH3.2~3.8

[0067] Silicate 10ppm (maximum, as SiO 2 count)

[0068] Total Dissolved Solids (T.D.S) 250ppm (Max)

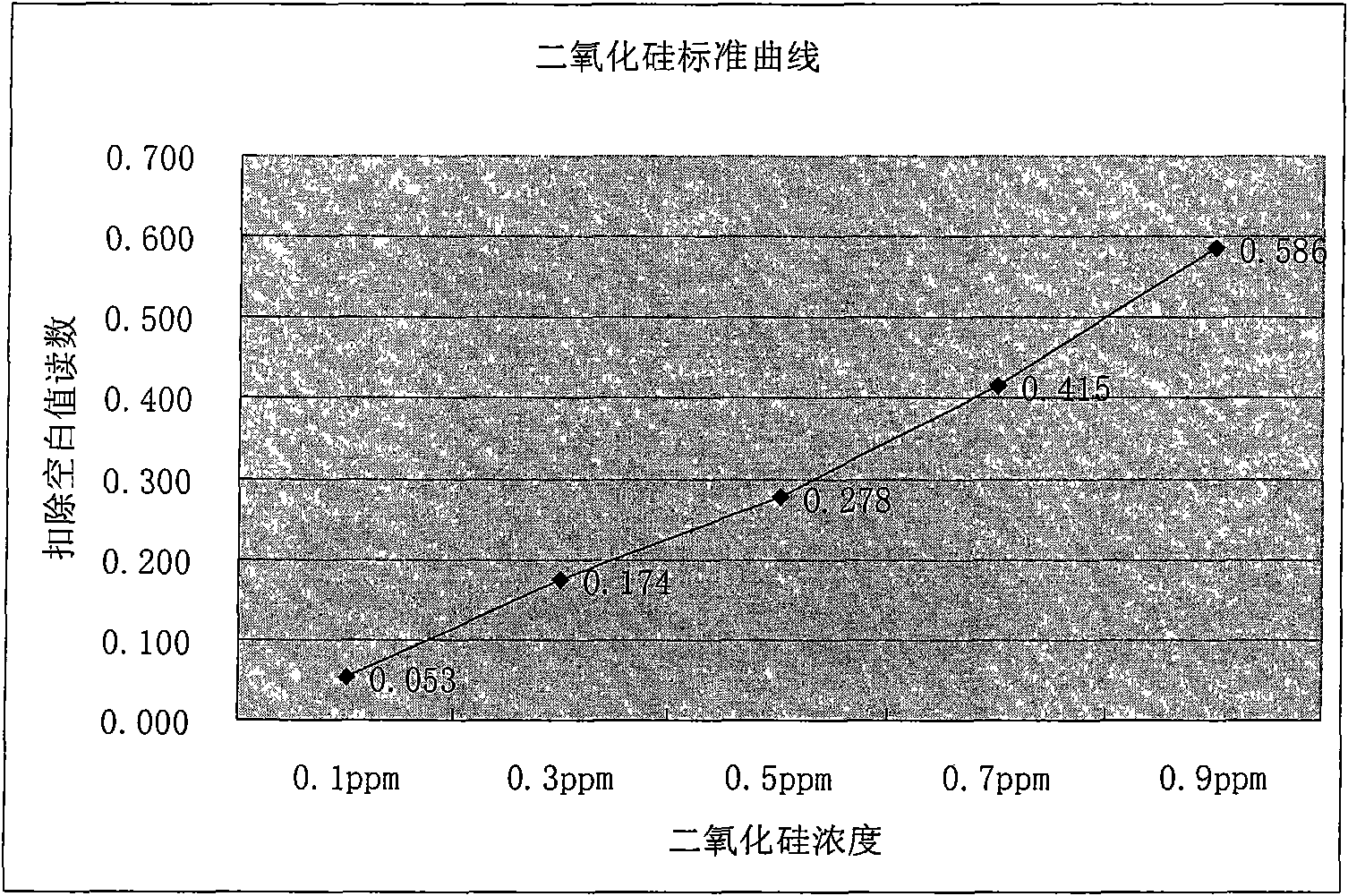

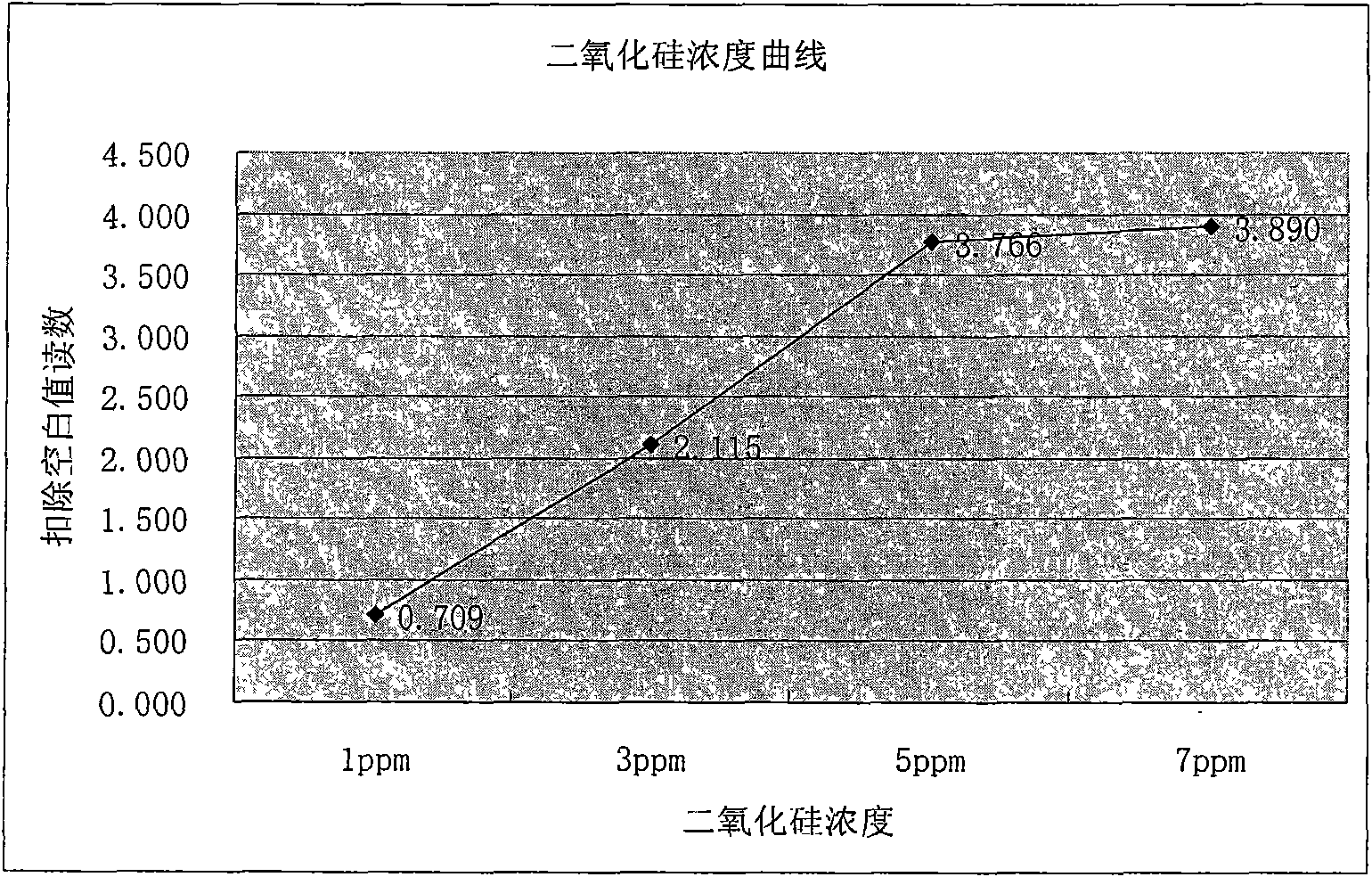

[0069] In order to ensure that the silicon dioxide content in the chromic acid anodizing solution is below 10 ppm, it is necessary to measure the silicon dioxide content in a colored solution such as the above-mentioned chromic a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com