Sump oil dehydration device

A dehydration device and waste oil technology, applied in the direction of electric/magnetic dehydration/emulsification, electric liquid separation, etc., can solve the problems of high oil content in drainage, high current tripping, poor dehydration effect, etc., to reduce oil content in drainage, avoid Disturb, enhance the effect of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

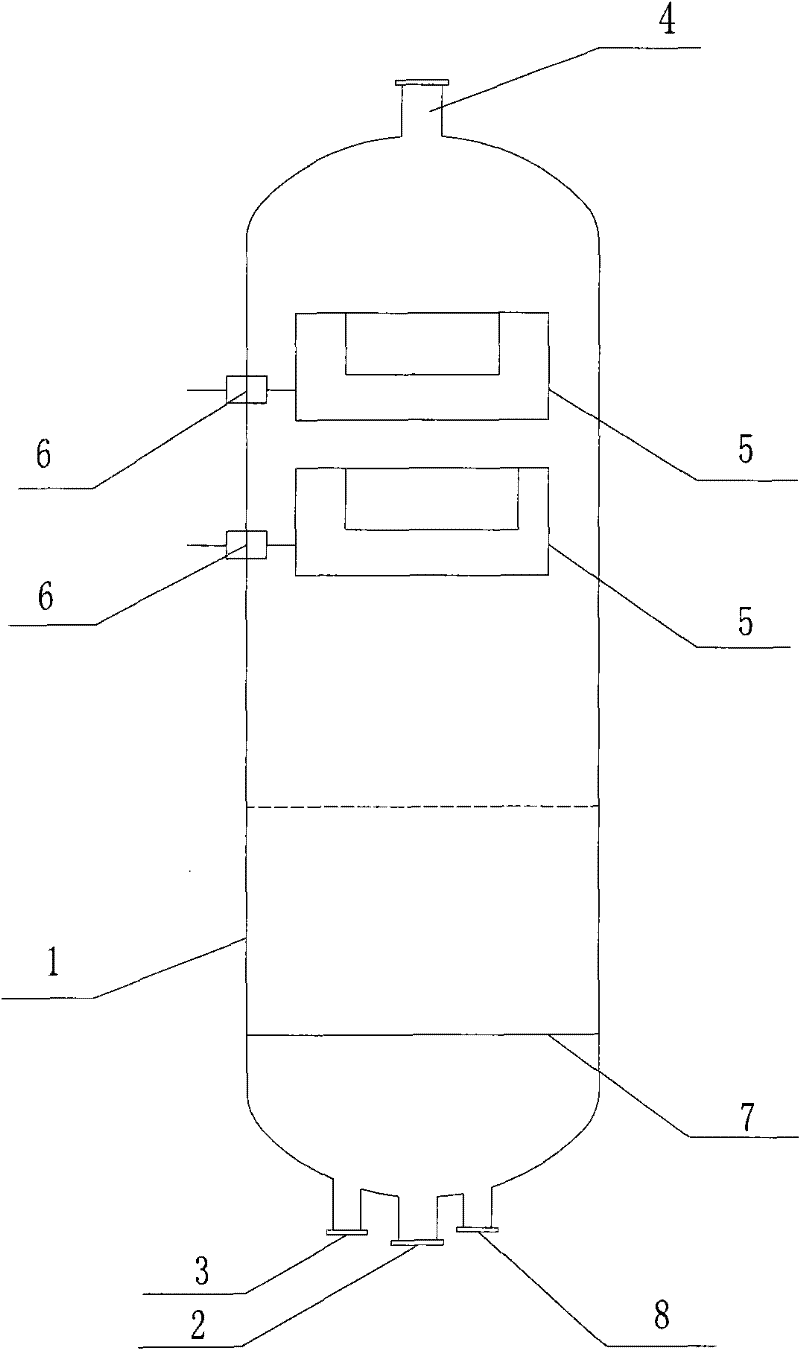

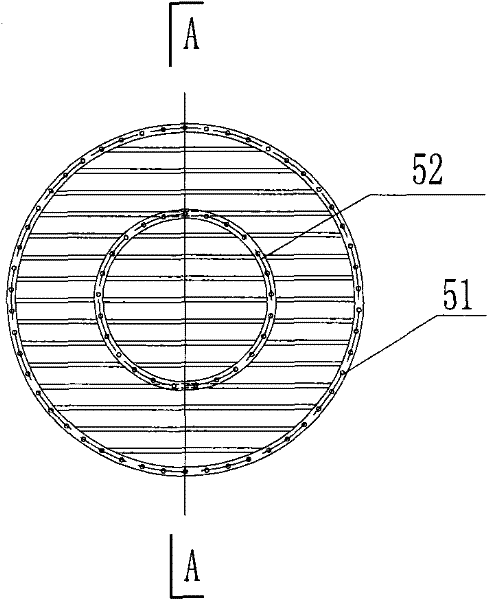

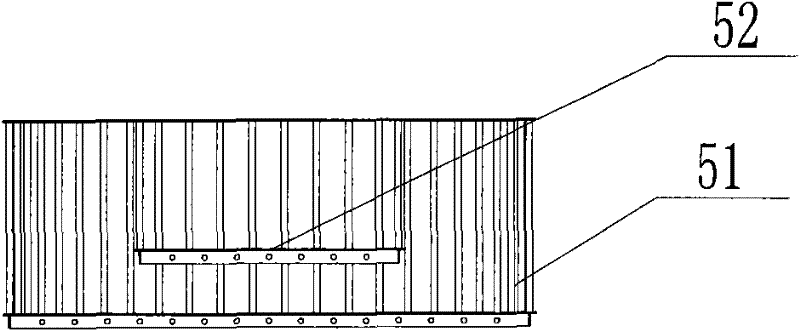

[0017] Such as figure 1 Shown is a kind of waste oil dehydration device of the present invention. It includes a tank body 1, two combined electrodes 5, a high-voltage introduction device 6, a sewage oil inlet pipe 2, a dehydrated sewage oil outlet pipe 4, a drain pipe 3, a sewage oil distributor 7 and a backwash inlet 8; the tank body 1 is a vertical tank , The combined electrode 5 is located in the upper middle part of the tank. The high-voltage introduction device 6 is connected to the combined electrode 5, the dirty oil distributor 7 is located in the middle and lower part of the tank, the dehydrated dirty oil outlet pipe 4 is located at the top of the tank, and the dirty oil inlet pipe 2, drain pipe 3 and backwash inlet 8 are located at the bottom of the tank .

[0018] figure 1 Among them, the dirty oil distributor 7 is set in the clear water layer below the oil-water boundary in the lower part of the tank, and is connected with the dirty oil inlet pipe 2. It is a circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com