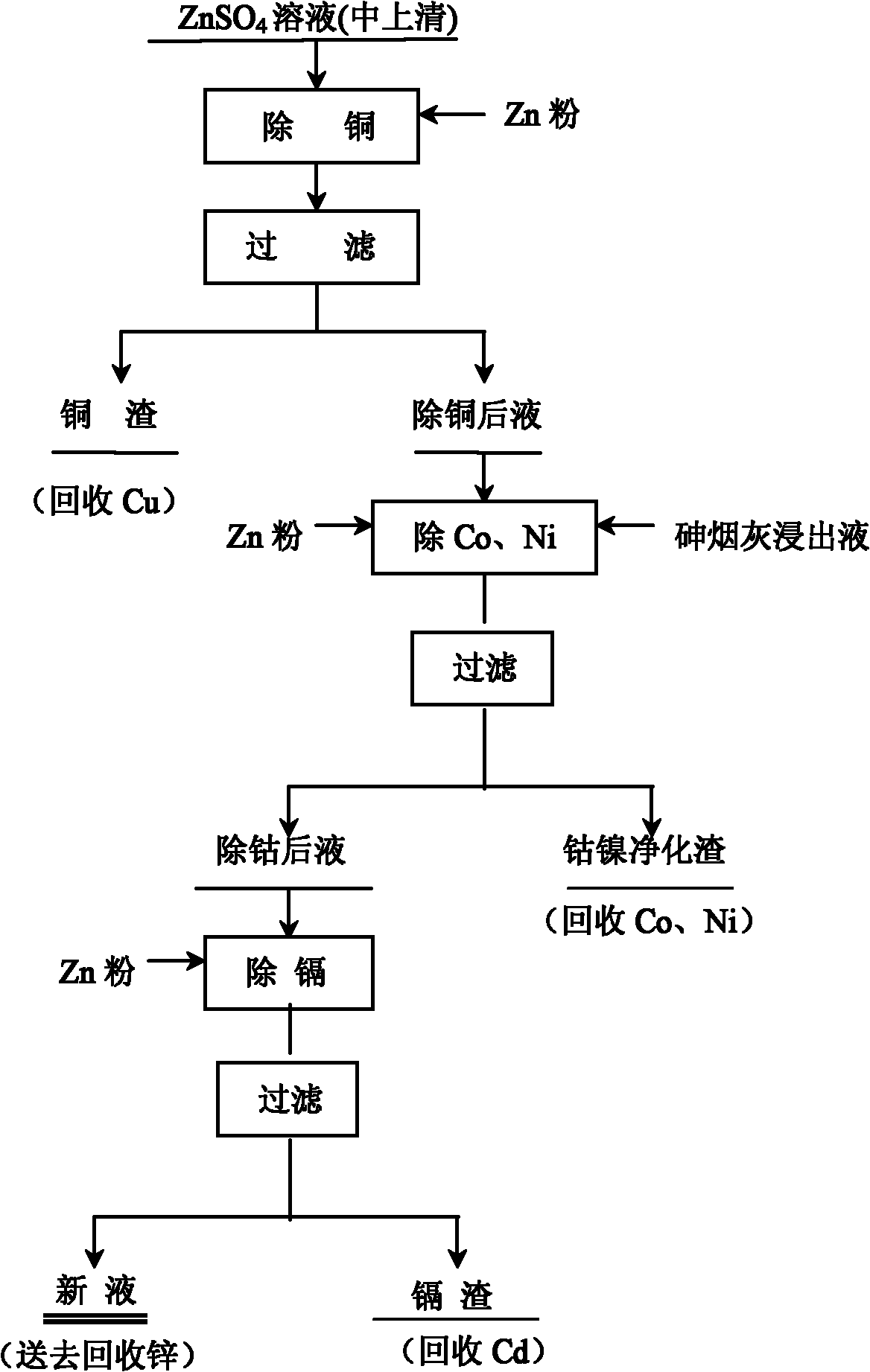

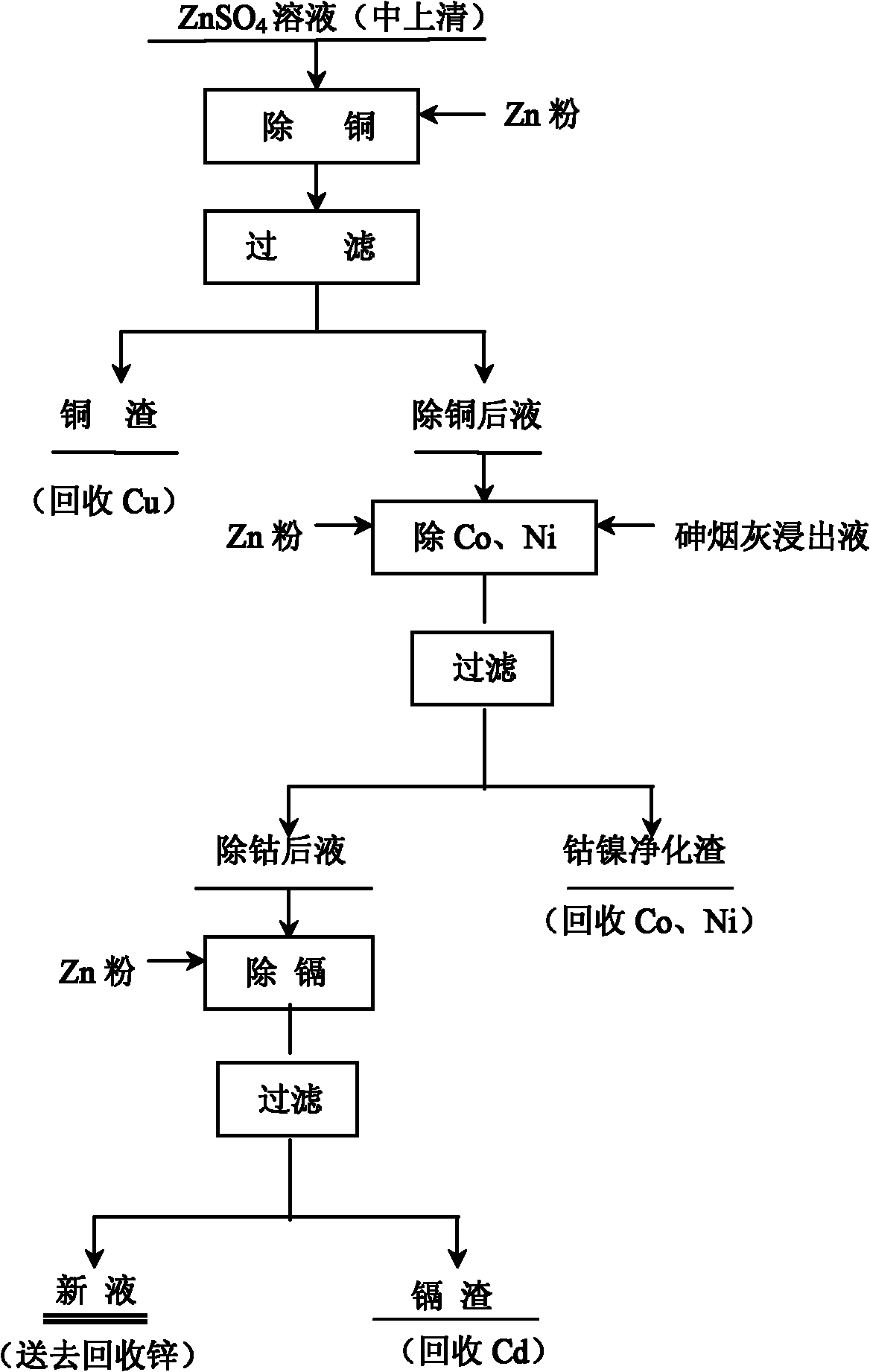

Method for purifying zinc sulfate solution and removing cobalt by using arsenic ash lixivium

A technology of zinc sulfate solution and leaching solution, which is applied in the direction of improving process efficiency, etc., can solve problems such as arsenic soot polluting the environment, and achieve the effect of solving environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Adopt the present invention to the zinc sulfate solution of wet method zinc smelting i.e. middle and supernatant 12M 3 Purify, the main impurity components in the supernatant are: Cu0.80g / L, Co0.010g / L, Ni0.010g / L, Cd0.01g / L. Follow these steps:

[0042] Step 1: Add zinc powder to remove Cu. The temperature is 70°C. Add zinc powder to the supernatant under constant stirring, and the reaction time is 60 minutes to obtain 150 mg / L of Cu in the liquid after copper removal.

[0043] Step 2: Four purification tanks are used for purification and cobalt removal, and the effective volume of each purification tank is 1m 3 , add copper removal solution, zinc powder and arsenic soot leaching solution to the purification tank at the same time under the condition of constant stirring. 3 / h, the weight of As in the arsenic soot leaching solution is half of the weight of Cu in the solution after copper removal plus the sum of the weight of Co and Ni, the potential of 1# tank is -550...

Embodiment 2

[0047] Adopt the present invention to hydrometallurgy zinc sulfate solution namely medium supernatant 12M 3 Purify, the main impurity components in the supernatant are: Cu1.2g / L Co0.025g / L, Ni0.023g / L, Cd0.05g / L. Follow these steps:

[0048] Step 1: Add zinc powder to remove Cu. The temperature is 70°C. Add zinc powder to the supernatant under constant stirring, and the reaction time is 50 minutes to obtain 200 mg / L of Cu in the liquid after copper removal.

[0049] Step 2: Four purification tanks are used for purification and cobalt removal, and the effective volume of each purification tank is 1m 3 , add copper removal solution, zinc powder and arsenic soot leaching solution to the purification tank at the same time under the condition of constant stirring. 3 / h, the weight of As in the arsenic soot leaching solution is half of the weight of Cu in the solution after copper removal plus the sum of the weight of Co and Ni, the potential of 1# tank is -550mV, the potential of...

Embodiment 3

[0053] Adopt the present invention to hydrometallurgy zinc sulfate solution namely medium supernatant 19.2M 3 After purification, the main impurities in the supernatant are: Cu1.50g / L, Co0.034g / L, Ni0.31g / L, Cd0.08g / L. Follow these steps:

[0054] Step 1: Add zinc powder to remove Cu. The temperature is 70°C. Add zinc powder to the supernatant under constant stirring, and the reaction time is 40 minutes to obtain 220 mg / L of Cu in the liquid after copper removal.

[0055] Step 2: Four purification tanks are used for purification and cobalt removal, and the effective volume of each purification tank is 1m 3 , add copper removal solution, zinc powder and arsenic soot leaching solution into the purification tank at the same time under the condition of constant stirring. 3 / h, the weight of As in the arsenic soot leaching solution is half of the weight of Cu in the solution after copper removal plus the sum of the weight of Co and Ni, the potential of 1# tank is -555mV, the pote...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com