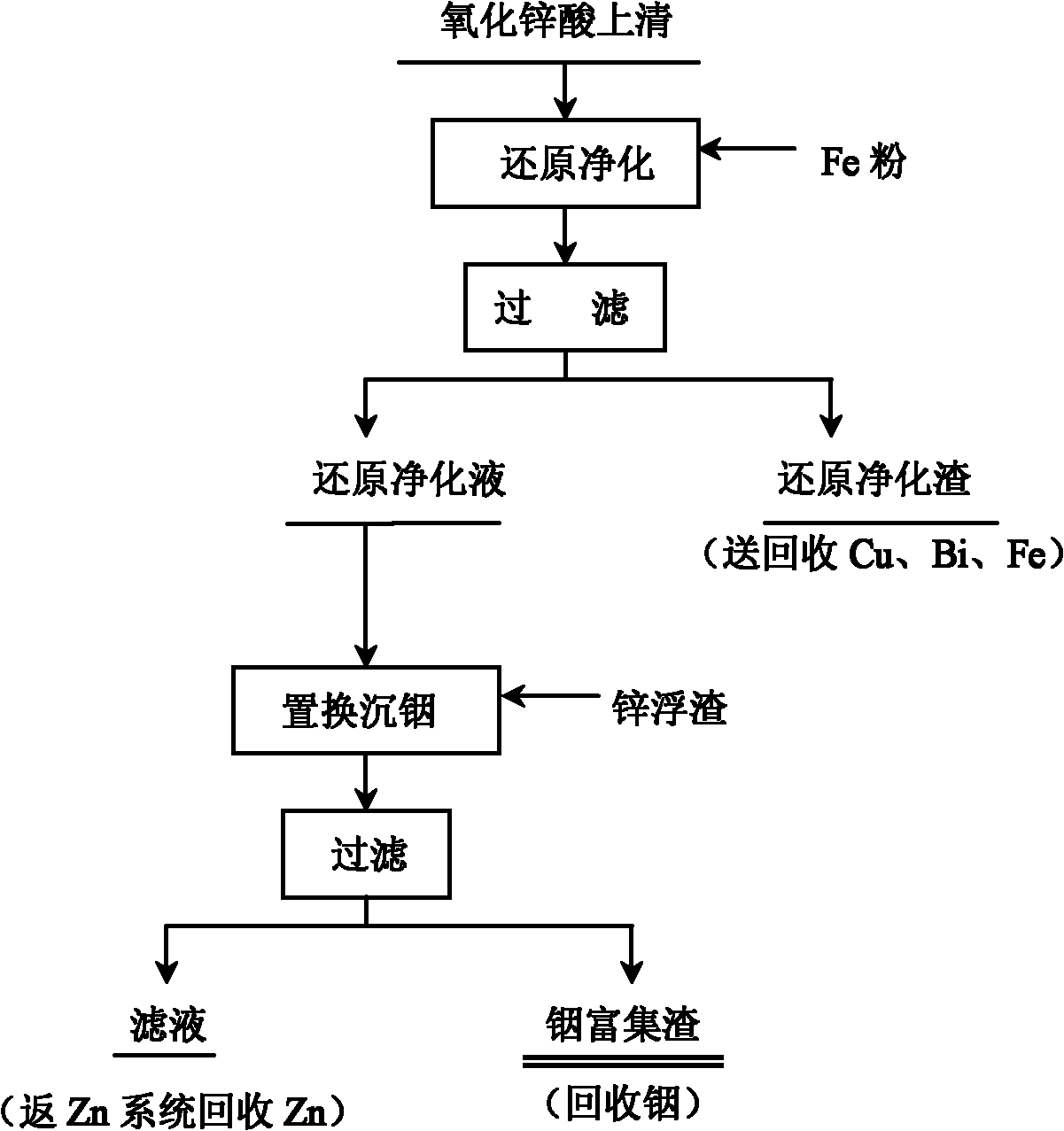

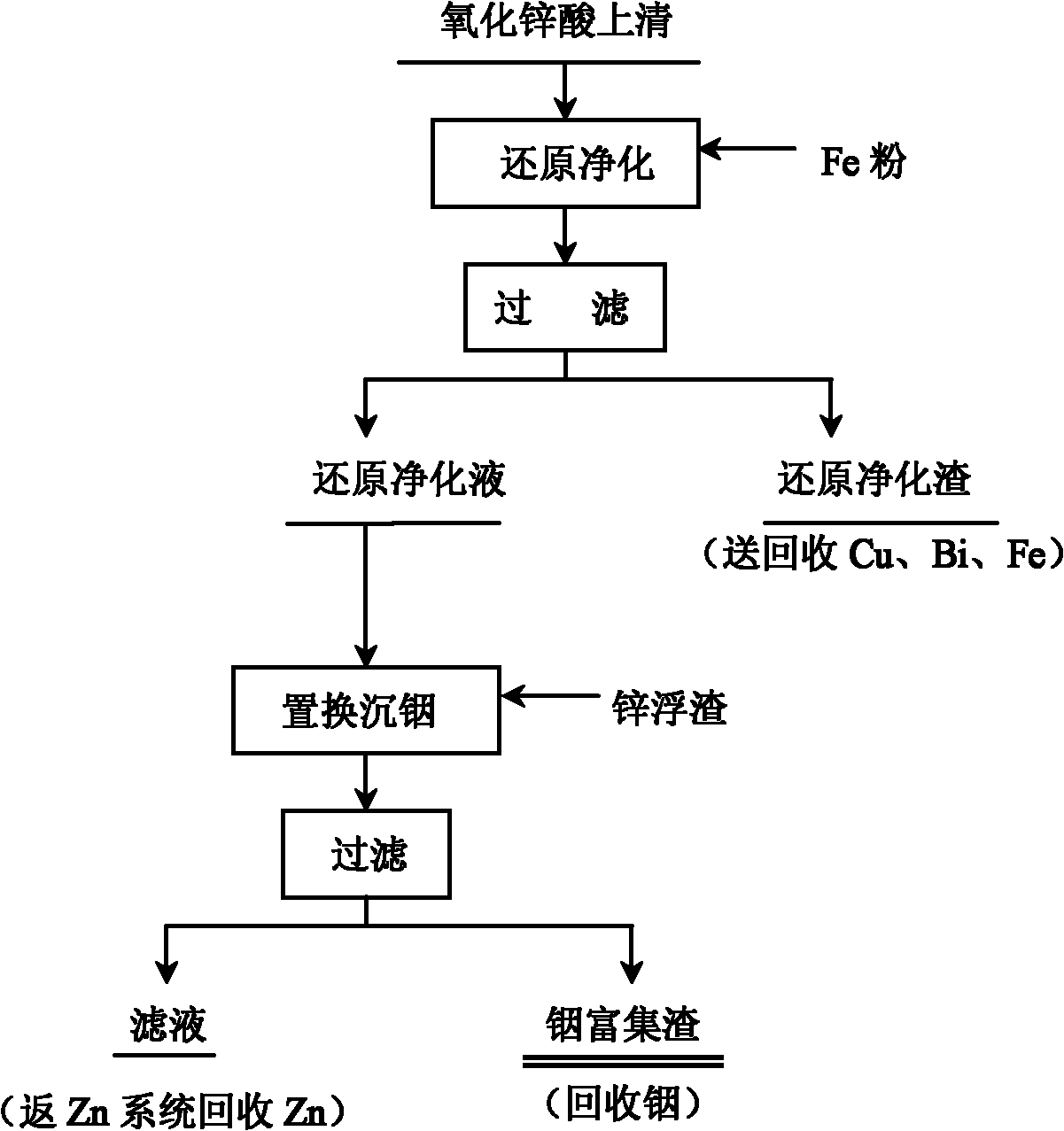

Method for enriching and recovering indium from zinc oxide acid supernate

A zinc oxide and supernatant technology, applied in the field of enrichment and recovery of indium, can solve the problems of difficulty in filtration, increase in recovery cost, and high impurity content, and achieve the effects of saving production cost and energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The present invention is used to enrich and recover indium from zinc oxide supernatant, 50 liters of zinc oxide supernatant, its components and concentrations: In0.55g / L, Fe 2+ 2.15g / L, Fe 3+ 17.92g / L, As1.67g / L, Cu1.36g / L, Bi0.048g / L, H 2 SO 4 20.31g / L; the main components and weight percentages of zinc scum are: Zn87.88%, Fe0.062%; Fe powder is added to the supernatant of zinc oxide acid, and the specific conditions for the reduction and purification of Fe powder are: temperature 50°C, Time 50min, add Fe powder under the condition of constant stirring, the amount of Fe powder added is Fe in the acid supernatant 3+ Half of the amount plus 1.1 times the sum of the Cu content. Filter to obtain the reduced and purified liquid and the reduced and purified slag; add zinc scum with a particle size of -60 mesh to the filtered reduced and purified liquid, and the specific conditions for adding zinc scum to sink indium are: temperature 65°C, time 2.0h, in Add zinc scum unde...

Embodiment 2

[0038]The present invention is used to enrich and recover indium from zinc oxide supernatant, 50 liters of zinc oxide supernatant, its components and concentrations: In0.55g / L, Fe 2+ 2.15g / L, Fe 3+ 17.92g / L, As1.67g / L, Cu1.36g / L, Bi0.048g / L, H 2 SO 4 20.31g / L; the main components and weight percentages of zinc scum are: Zn87.88%, Fe0.062%, add Fe powder to the supernatant of zinc oxide acid, the specific conditions for Fe powder reduction and purification are: temperature 60°C, Time 40min, add Fe powder under the condition of constant stirring, the amount of Fe powder added is Fe in the acid supernatant 3+ Half of the amount plus 1.3 times the sum of the Cu content. Filter to obtain the reduced liquid and reduced slag; add zinc scum with a particle size of -80 mesh to the filtered reduced and purified liquid, and the specific conditions for adding zinc scum to sink indium are: temperature 70°C, time 2.0h, stirring continuously Zinc scum is added under certain conditions, t...

Embodiment 3

[0040] Zinc oxide supernatant 50 liters, its composition and concentration: In0.55g / L, Fe 2+ 2.15g / L, Fe 3+ 17.92g / L, As1.67g / L, Cu1.36g / L, Bi0.048g / L, H 2 SO 4 20.31g / L; the main components and weight percentages of zinc scum are: Zn87.88%, Fe0.062%, add Fe powder to the supernatant of zinc oxide acid, the specific conditions for Fe powder reduction and purification are: temperature 70 °C, Time 30min, add Fe powder under the condition of constant stirring, the amount of Fe powder added is Fe in the acid supernatant 3+ Half of the amount plus 1.2 times the sum of the Cu content. Filter to obtain reduced liquid and reduced residue;

[0041] Add zinc scum with a particle size of -80 mesh to the reduced and purified liquid obtained by filtration. The specific conditions for adding zinc scum to sink indium are: temperature 75°C, time 1.5h, add zinc scum under constant stirring, zinc The amount of scum added is controlled by the end point pH value, which is controlled at 4.8. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com