Networked controller of high-frequency inverter power supply and control method thereof

A high-frequency inverter and controller technology, which is applied to a high-frequency inverter power supply control device and its control field, can solve the problem that the high-frequency induction heating inverter power supply cannot meet industrial production, cannot realize networked remote monitoring, and workers operate labor. Intensity and other problems, to achieve the effect of improving product competitiveness, reducing controller costs, and reducing enterprise operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

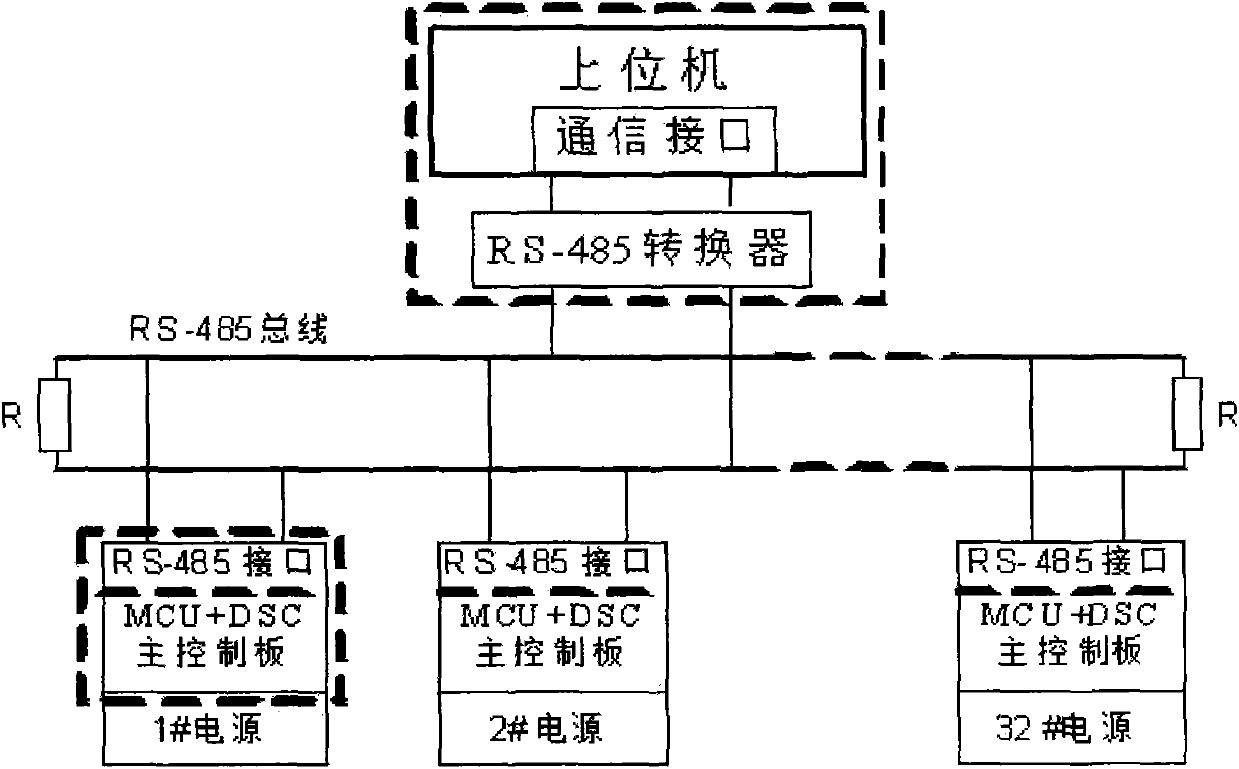

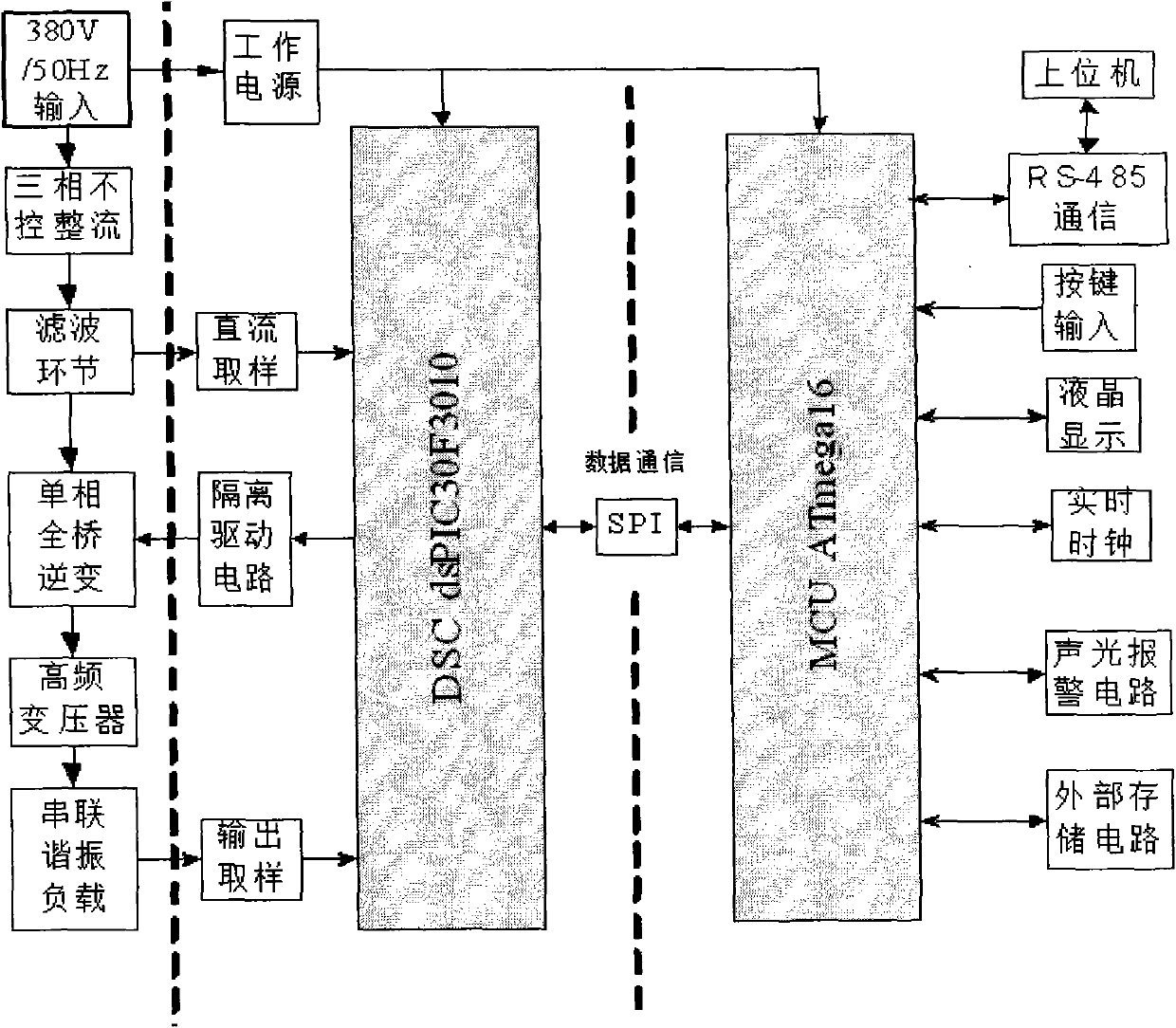

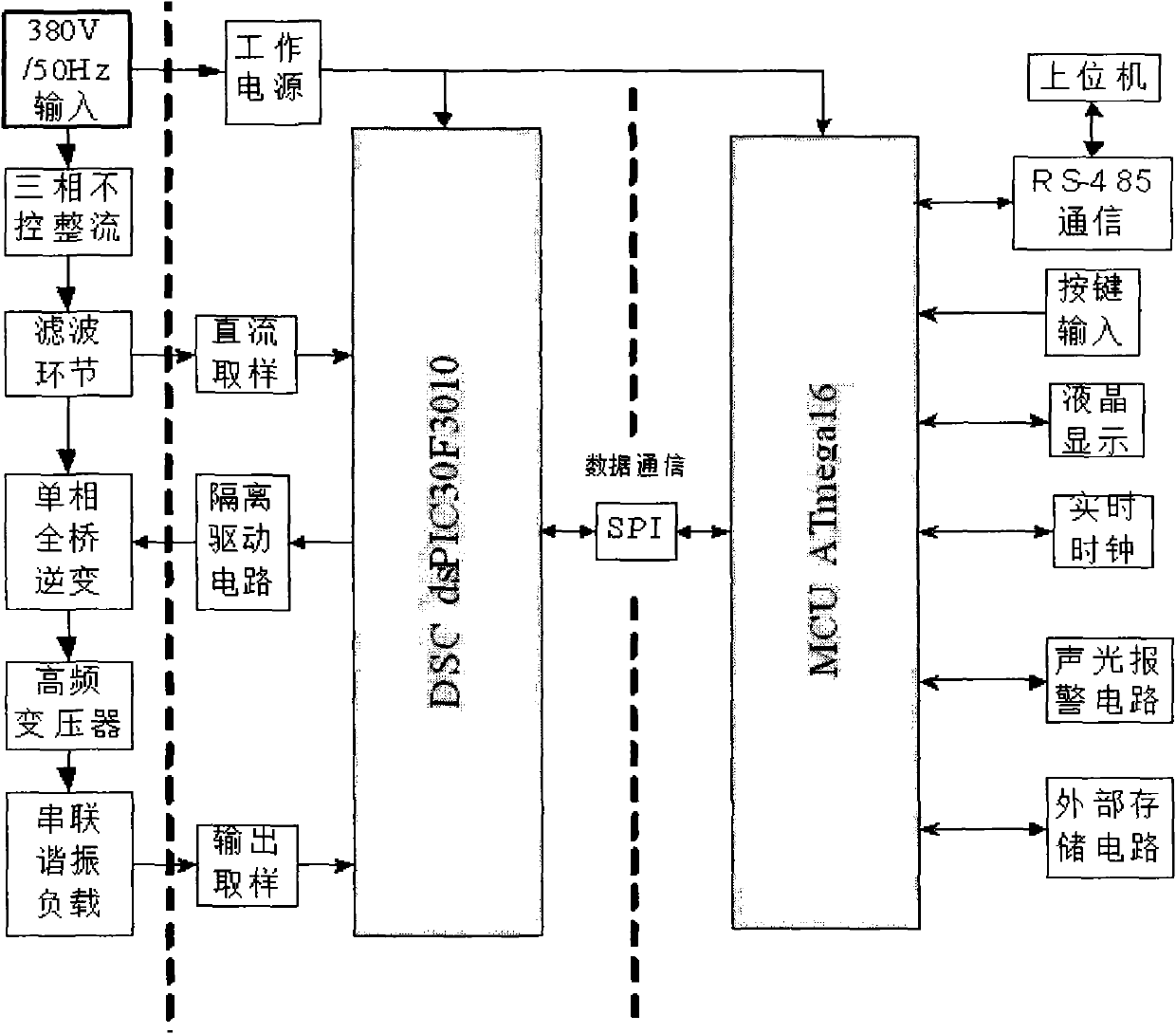

[0012] Such as figure 1 As shown, the high-frequency inverter power network controller network can form a high-frequency induction heating inverter power network control system. The system includes a host computer, an RS-485 converter connected to the communication interface of the host computer, an RS-485 bus connected to the RS-485 converter, and at least one of the high-frequency inverters connected to the RS-485 bus. The variable power supply network controller is connected to control the corresponding high-frequency inverter power supply. Under normal circumstances, the system can connect 32 controllers at the same time, monitor 32 power supplies, and can also use repeaters to amplify the signal for expansion. Each high-frequency inverter power network controller collects the parameters and status of the power supply in real time and feeds them back to the host computer. The host computer processes and displays the parameters, and sends instructions or information to eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com