Plasma cathode and protecting method thereof

A plasma and cathode technology, which is applied in the field of plasma technology and chemical synthesis, can solve the problems of low energy utilization rate and ablation, and achieve the effect of high energy utilization rate and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

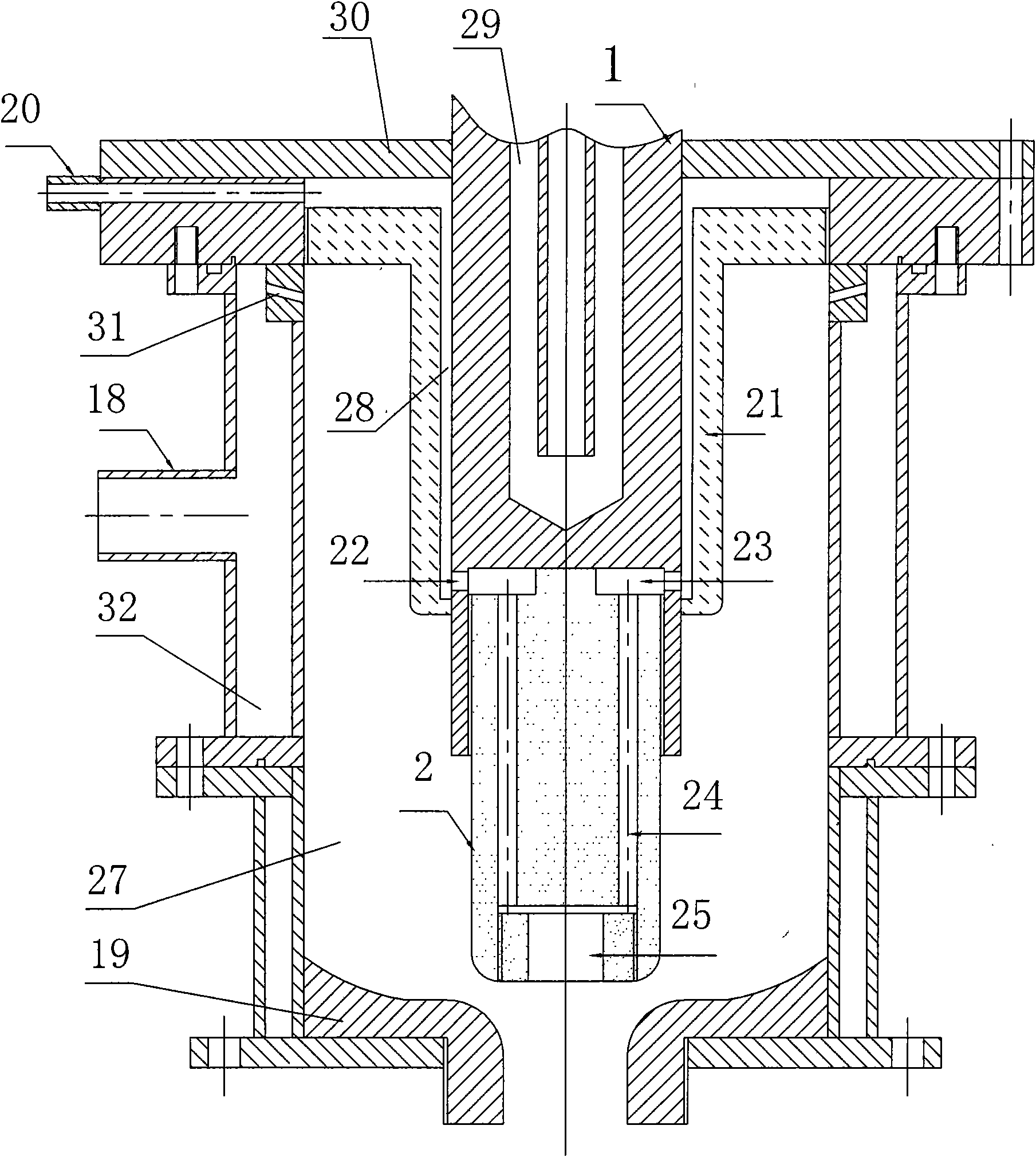

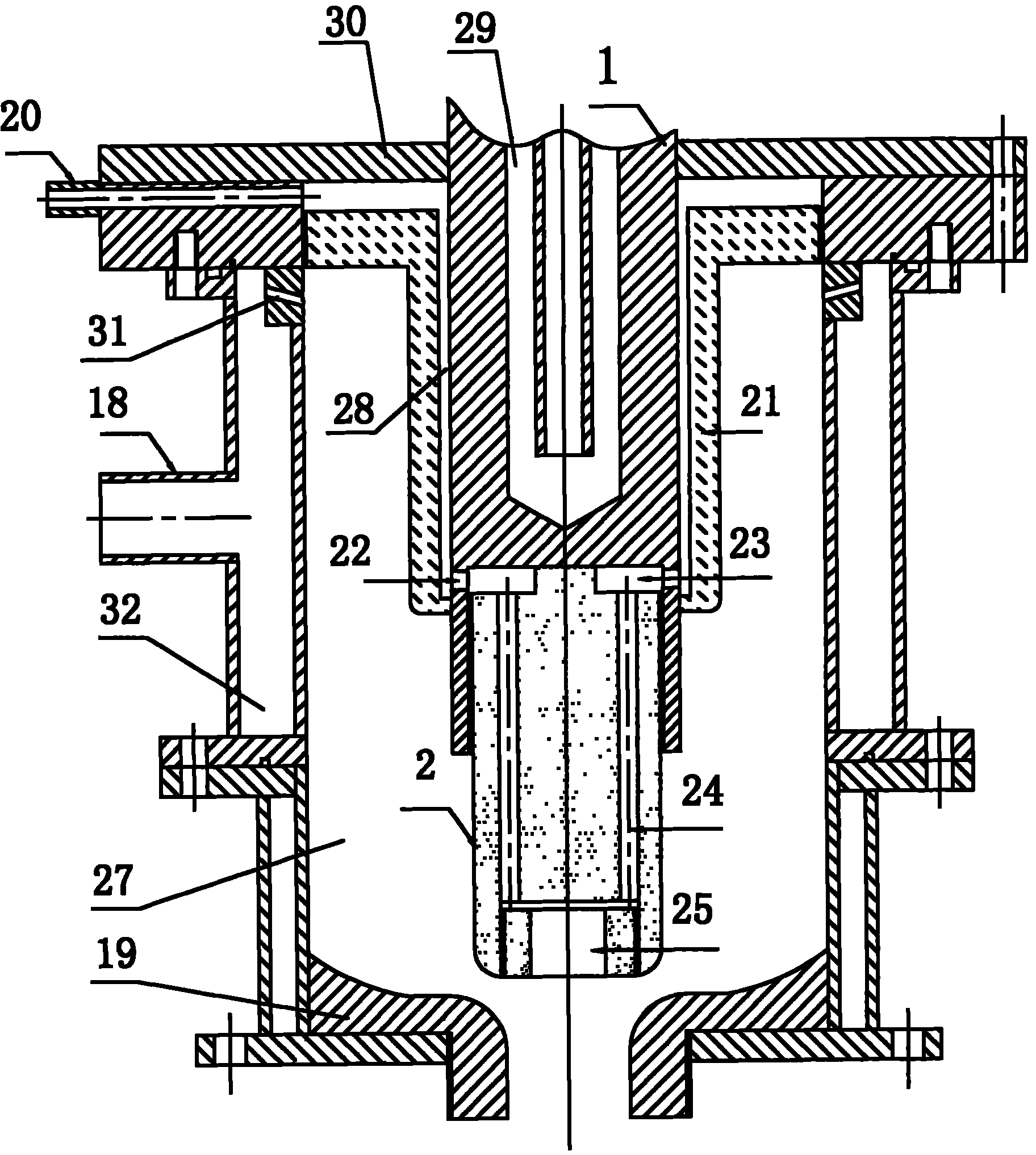

[0023] Such as figure 1 As shown, the plasma device is provided with an anode 19 and a cathode. The cathode extends into the anode cavity 27. The cathode is a water-cooled cathode (a cathode with a water-cooled channel 29) made of stainless steel 1 and a hollow cathode 2 made of graphite. It is connected to the cathode of the plasma device by screw thread. An insulating medium 21 is provided outside the water-cooled cathode 1 to separate the water-cooled cathode 1 from the anode cavity 27. A gap 28 is formed between the water-cooled cathode 1, the insulating medium 21 and the anode cover 30 outside the water-cooled cathode 1, and the inlet II20 communicates with the gap 28 . An annular gas cavity 32 is installed outside the anode cavity 27, and the outside of the annular gas cavity 32 is communicated with the inlet I 18, and a hole IV31 is opened on the inner wall of the annular gas cavity 32. The hollow cathode 2 is provided with an inner cavity 25 and a hole III24. One end o...

Embodiment 2

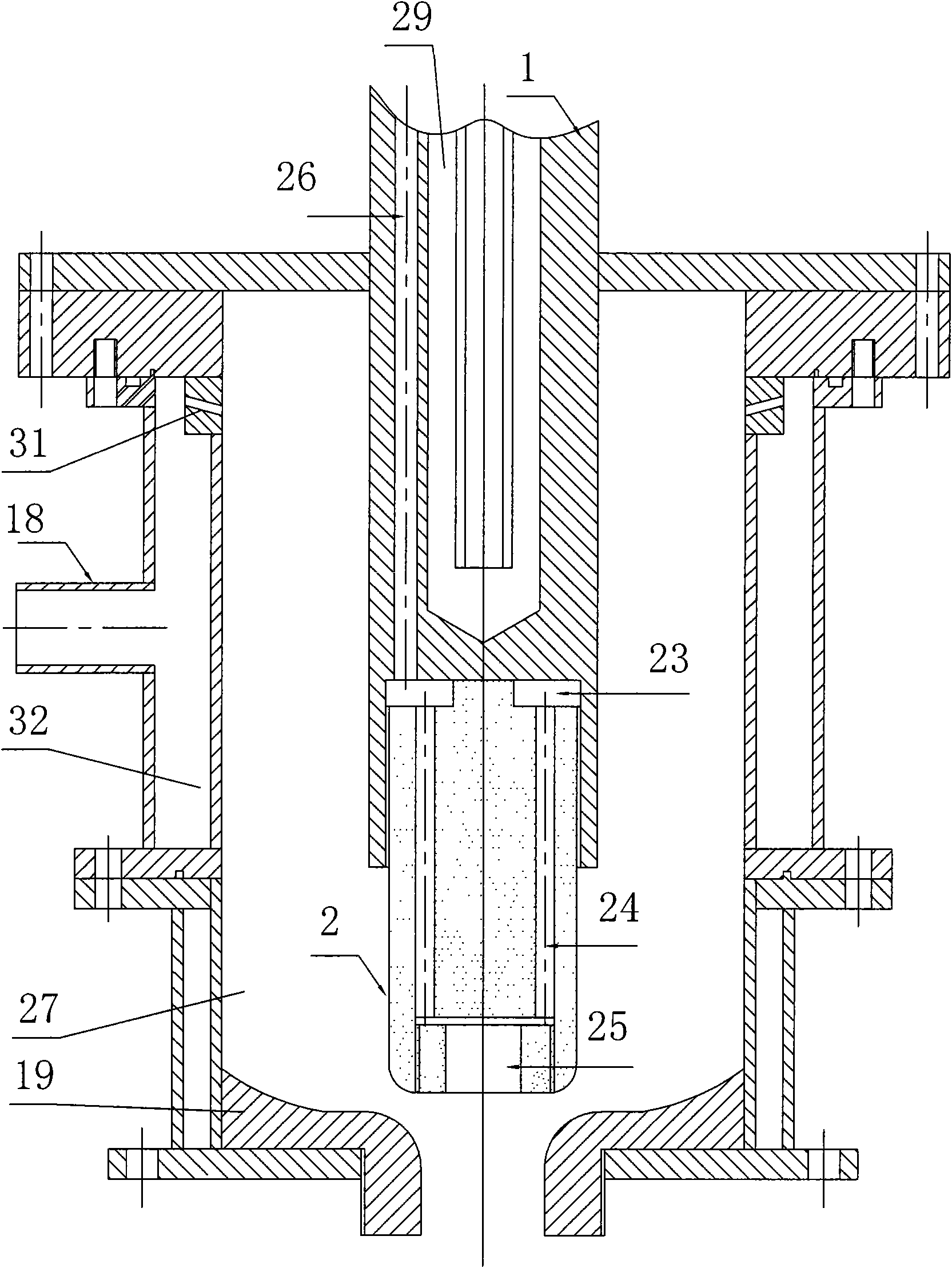

[0025] Such as figure 2 As shown, the plasma device is provided with an anode 19 and a cathode. The cathode extends into the anode cavity 27. The outside of the anode cavity 27 is equipped with an annular gas cavity 32. The outside of the annular gas cavity 32 is connected to the inlet I 18 and is on the inner wall of the annular gas cavity 32. There is a channel IV31. The cathode is a water-cooled cathode 1 made of stainless steel, and a hollow cathode 2 made of silicon carbide is screwed to form the cathode of the plasma device. An annular gas is opened between the water-cooled channel 29 of the water-cooled cathode 1 and the outer wall of the water-cooled cathode 1. In the channel 26, the hollow cathode 2 is provided with an inner cavity 25 and a hole III24. One end of the hole III24 is connected to the inner cavity 25, and the other end of the hole III24 communicates with the gas channel 26 through the hole II23. The protective gas passes through the gas channel 26 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com