Method for preparing freeze-dried jackfruit

A technology of carpine and pineapple, which is applied in the field of preparation of freeze-dried carpine by using freeze-drying technology, and can solve the problems of freeze-dried carpine products that have not yet been seen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

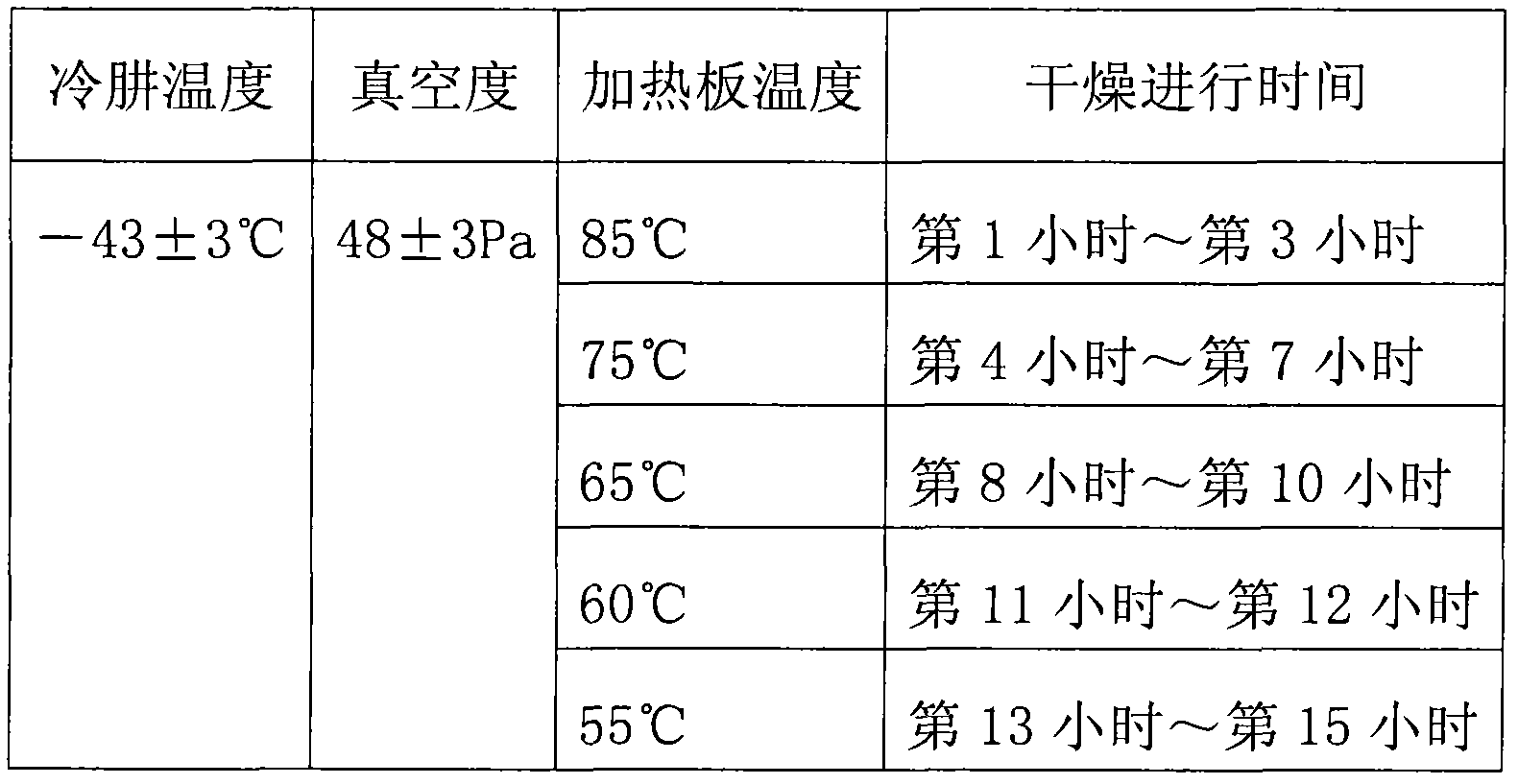

[0010] Select 600kg of wood pineapple that is disease-free, non-rotten, and eight-mature, cut open the wood pineapple, dig out the fruit buds, then cut open the fruit buds, remove the core and leave the meat; wash the wood pineapple meat twice with running drinking water, wash Debris, cut into chunks; soak in 0.3g / L sodium hypochlorite solution for 5 minutes, rinse with drinking water, drain, put on a plate, freeze to -28°C, and then put the frozen wood pineapple into the freezer vacuum Freeze-dried wood pineapple can be obtained after drying in the drying chamber of the dryer, and the parameter control in the freeze-vacuum dryer is shown in Table 1.

[0011] Table 1. Parameter control in the freeze vacuum dryer

[0012]

Embodiment 2

[0014] In this embodiment, except that the 0.5 g / L sodium hypochlorite solution was used to soak the pineapple for 4 minutes, all the other process steps and process parameters were the same as in Example 1.

Embodiment 3

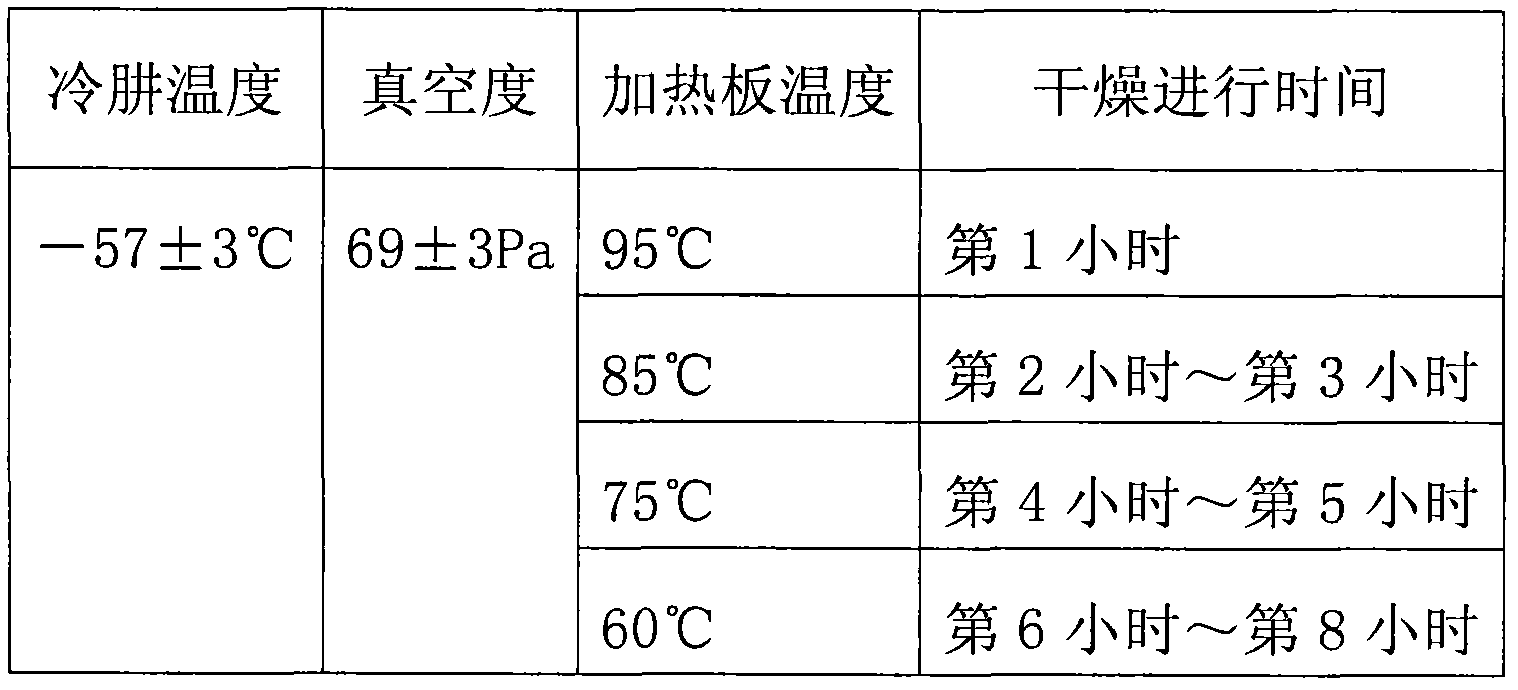

[0016] Select 800kg of wood pineapple that is disease-free, non-rotten and nearly mature, cut open the wood pineapple, dig out the fruit buds, then cut open the fruit buds, remove the core and leave the meat; wash the wood pineapple meat three times with running drinking water, wash the broken pieces Chips, cut into chunks; soak in 5g / L hydrogen peroxide solution for 3 minutes, rinse with drinking water, drain, put on a plate, and freeze to -35°C; then put the frozen wood pineapple into the freezer vacuum Freeze-dried wood pineapple is obtained after drying in the drying chamber of the dryer, and the parameter control in the freeze-vacuum dryer is shown in Table 2.

[0017] Table 2. Parameter control in the freeze vacuum dryer

[0018]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com