Manufacturing method of safe transfusion system based on bubbling point pressure principle

A technology of bubble point pressure and manufacturing method, which is applied in the field of medical devices, can solve the problems of manufacturing process, cost, complicated clinical use, long exhaust time, complicated operation, etc., so as to reduce the risk of employment, simple manufacturing process and simple type. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

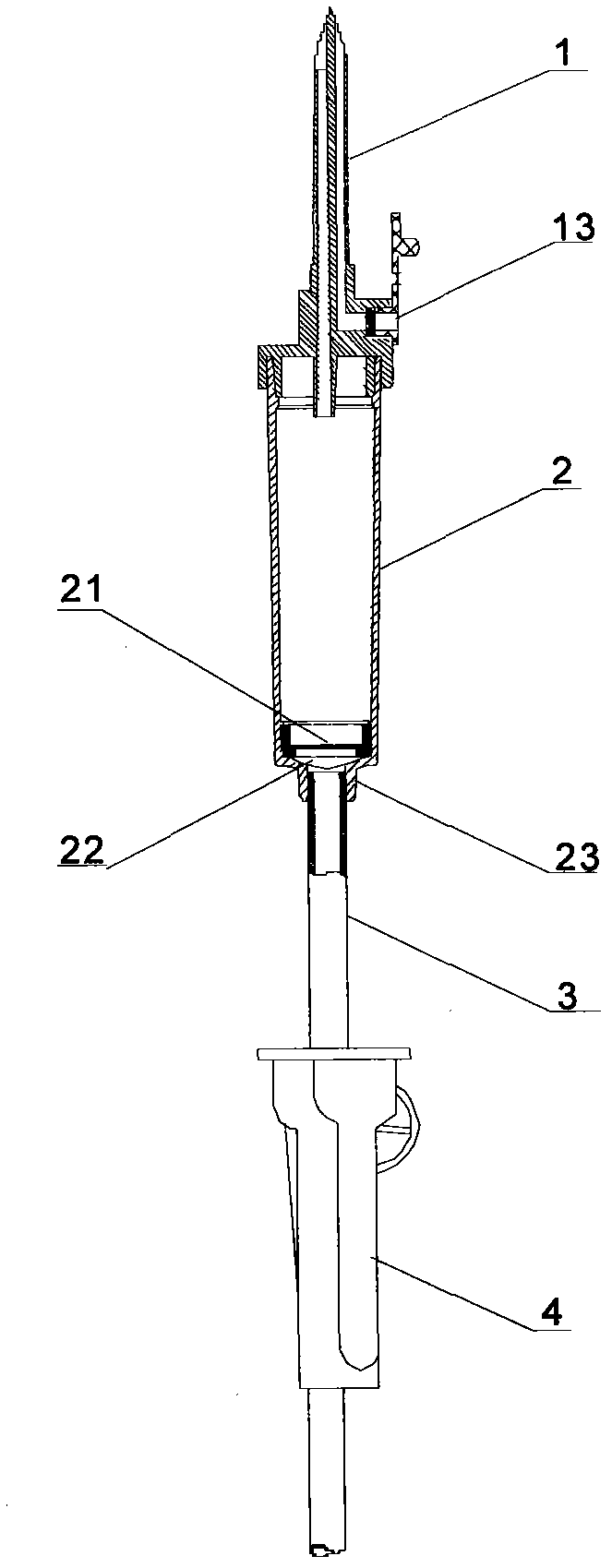

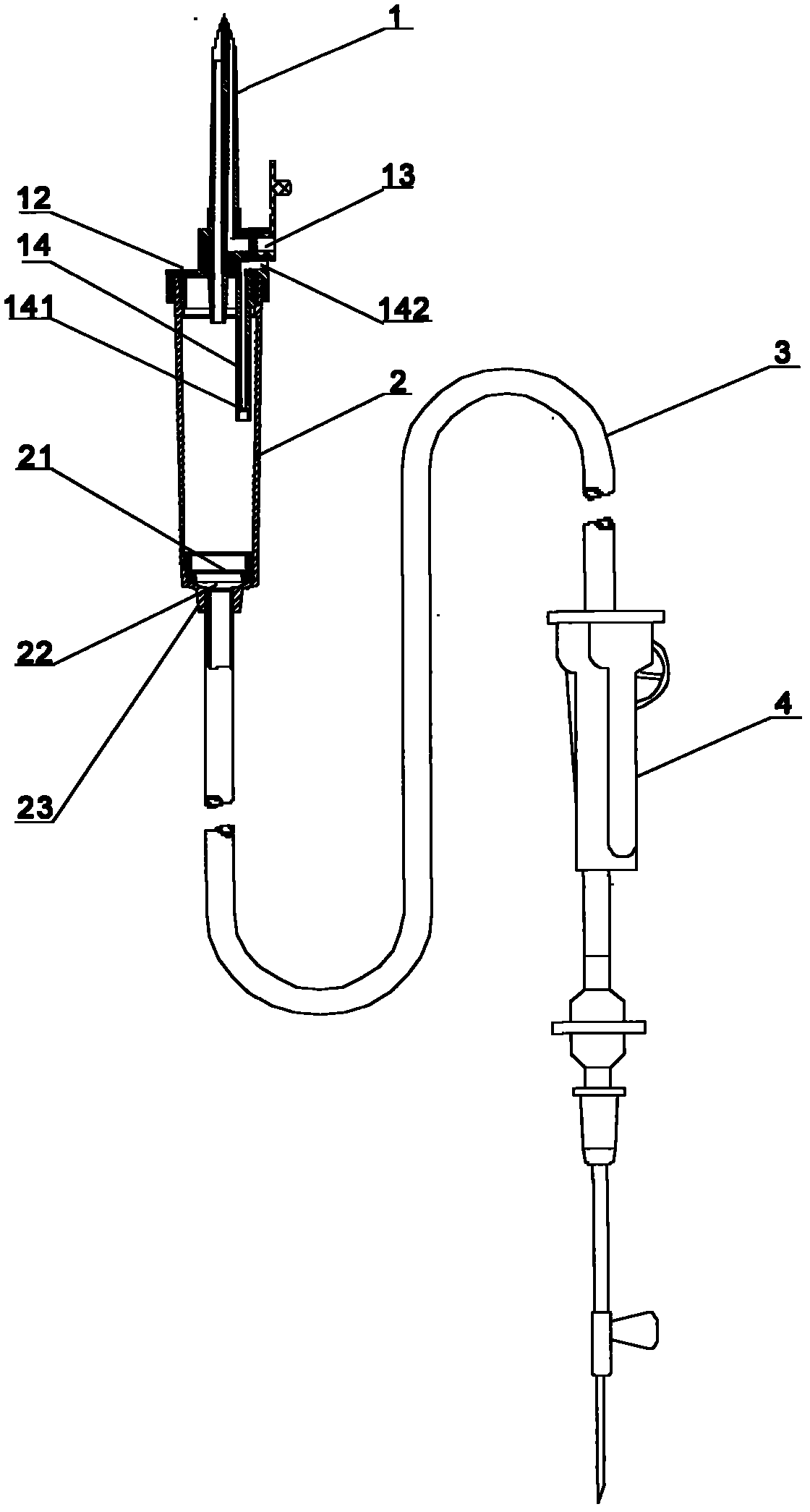

[0051] figure 2 It is a schematic diagram of the typical structure of Example 1 of the safety infusion set based on the principle of bubble point pressure. Such as figure 1 As shown, the infusion set is composed of a piercer 1, an air inlet 13, a drip funnel 2, a liquid medicine filter medium 21, an exhaust pipe 14, a pipeline 3 and a regulator 4, wherein one end of the exhaust pipe 14 extends into the drip In the middle of the inner cavity of the bucket 2, one end of the exhaust pipe 14 is covered with an air filter medium 141 that exhausts and does not drain liquid. On this basis, the method can be divided into:

[0052] (1) Install an exhaust pipe 14 extending into the middle part of the inner cavity of the dropping funnel 2, and the exhaust pipe 14 extends into the end opening position of the inner cavity of the dropping funnel 2 or covers and installs a row of exhaust pipes near the passageway where the exhaust pipe 14 extends into the end. The air filter medium 141 th...

Embodiment 2

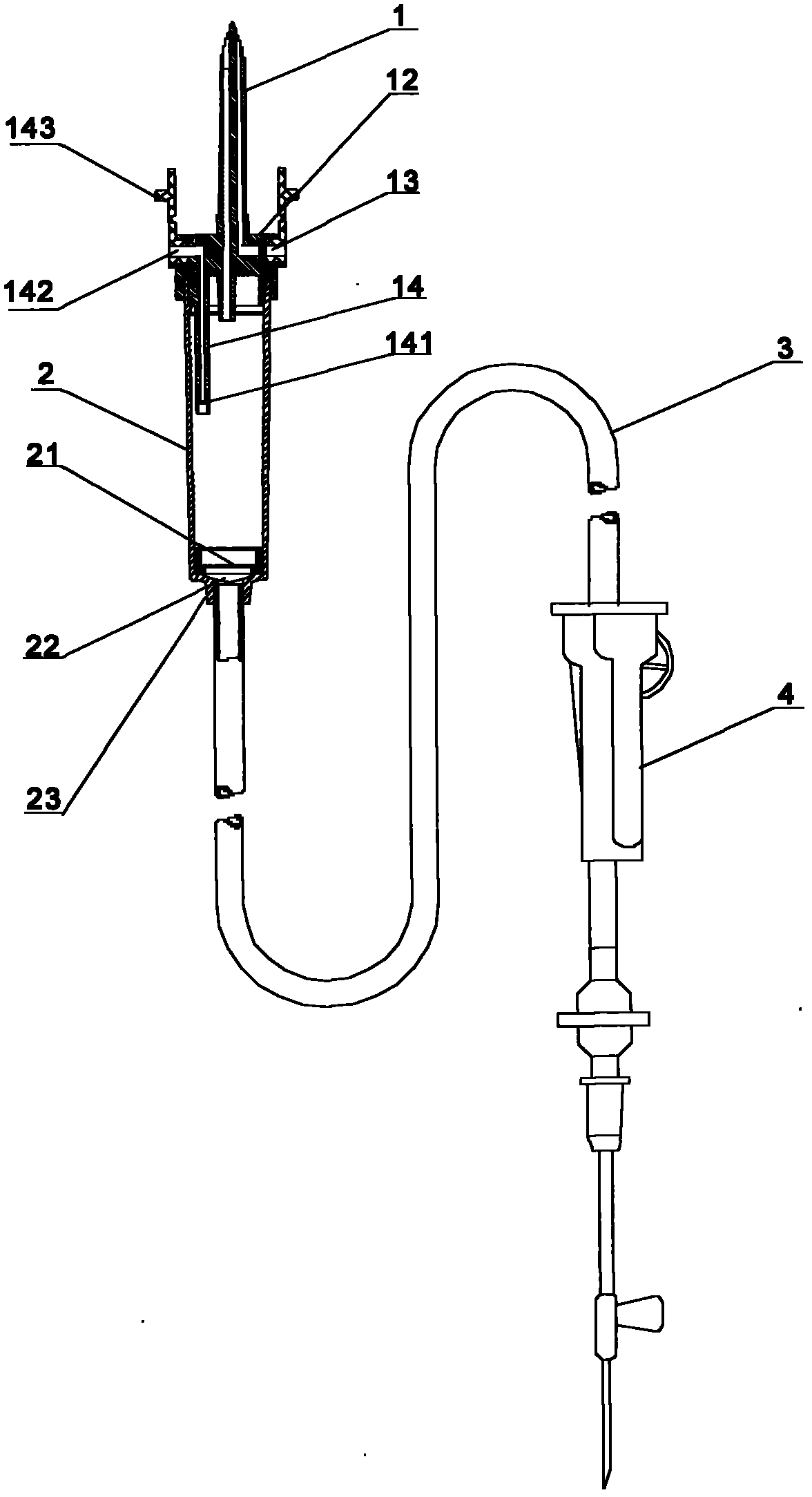

[0063] image 3 It is a schematic diagram of the typical structure of Example 2 of the safety infusion set based on the principle of bubble point pressure. Such as image 3 As shown, this embodiment is basically the same as Embodiment 1 in terms of principle, manufacturing method and use. The only difference is that in this embodiment, the exhaust pipe 14 is independently arranged on a side that is not on the same side as the air intake piece 13. At the position where the exhaust pipe 14 communicates with the outside, a cap 143 that can open or close the exhaust outlet 142 is installed.

[0064] This embodiment is the same as Embodiment 1, and can realize all the performances of Embodiment 1, and on this basis, once encountering an extreme situation, such as a large-dose infusion emergency situation, in order to avoid the risk of possible insufficient flow, in the extreme When used in occasions, the cap 143 should be opened, exhausted as in the method of Example 1, after com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com