Environmental-protection treatment system for production process of lead-acid battery polar plate

A treatment system, lead-acid battery technology, applied in the direction of removing smoke and dust, using liquid separation agent, cleaning methods and appliances, etc., can solve the problems of environmental pollution, environmental impact, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

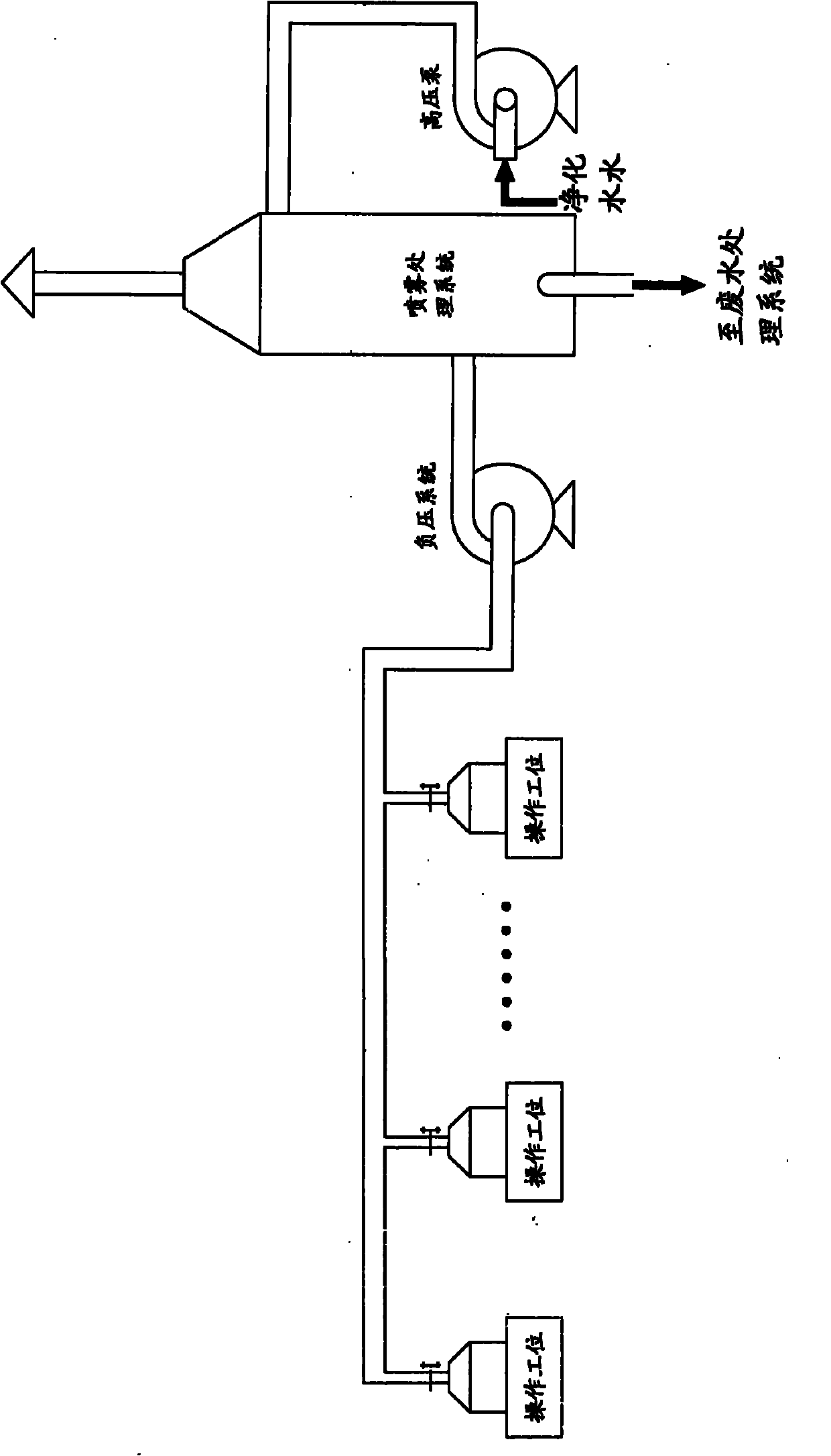

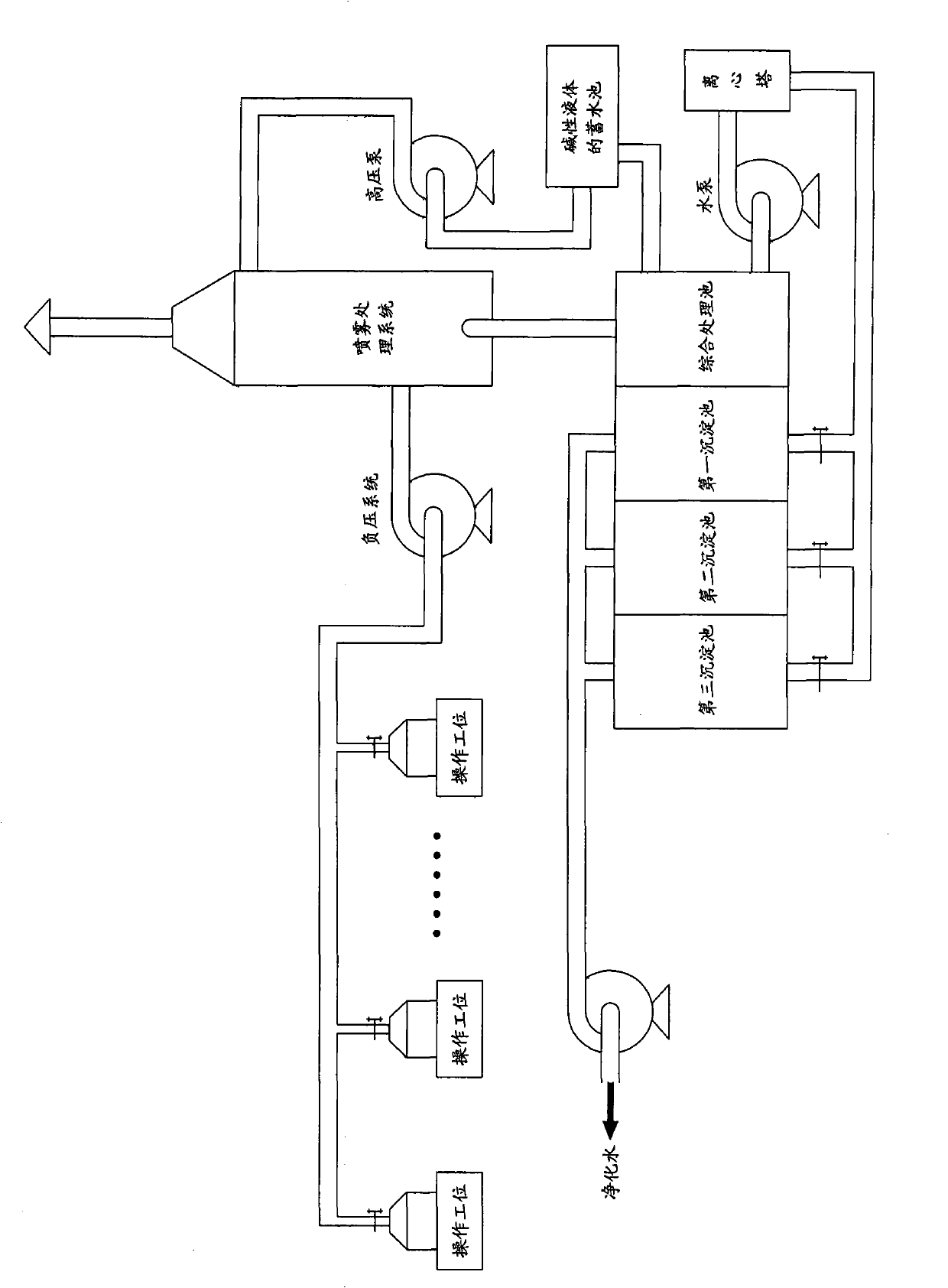

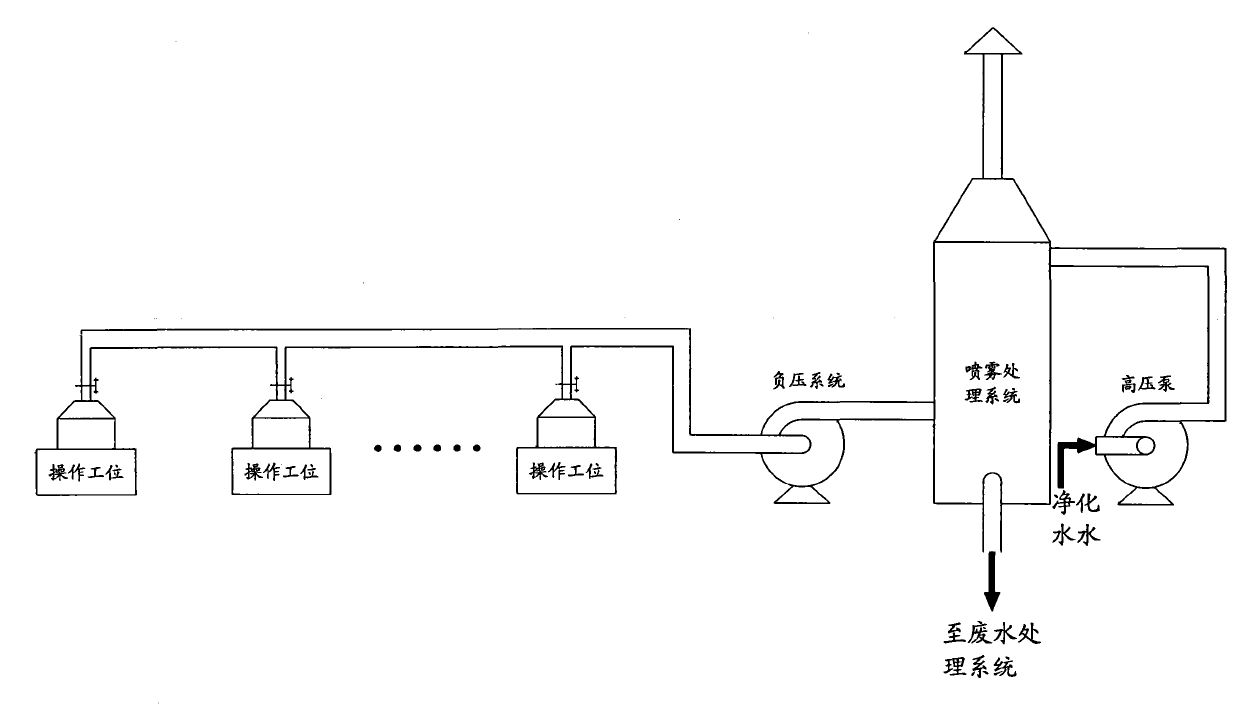

[0012] refer to figure 1 and figure 2 , the environmental protection treatment system for the production process of lead-acid battery plates, including the collection and treatment system of lead dust, lead fume and lead vapor, and the collection and treatment system of acid mist and waste acid; the collection and treatment system of lead dust, lead fume and lead vapor includes a negative The inlet port of the negative pressure system is connected to the discharge port of the corresponding process operation station, and the outlet port of the negative pressure system is connected to the spray treatment system. The lead dust, lead smoke and lead vapor produced by each operation station Under the action, it is drawn into the discharge port and enters the spray treatment system. There are a large number of nozzles on the top of the spray treatment system to form a spray envelope in the system. The lead particles in the gas are absorbed by the spray and enter the wastewater treat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com