Composite photocatalyst and preparation method thereof

A catalyst and composite light technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of low hydrogen production catalyst activity, low hydrogen production rate, etc., and achieve simple installation and low price. , the effect of high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

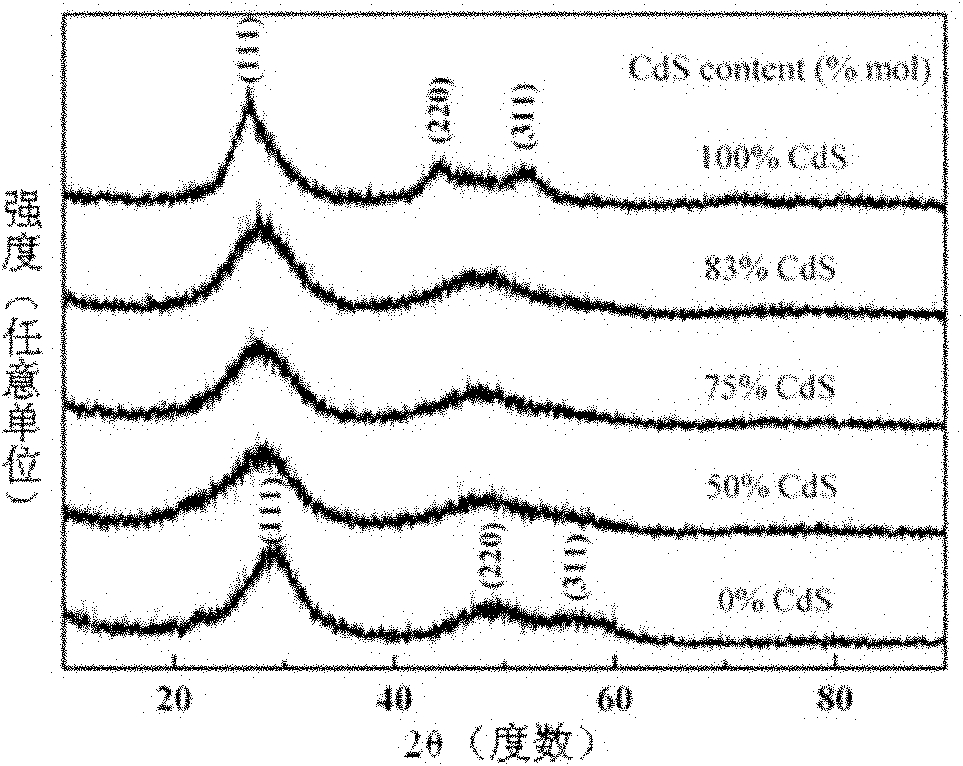

[0016] Specific implementation mode one: the composite photocatalyst of this implementation mode is made of Zn(Ac) 2 2H 2 O, Cd(Ac) 2 2H 2 O, made from the third main group compound and thioacetamide; Zn(Ac) 2 2H 2 O and Cd(Ac) 2 2H 2 The molar ratio of O is 1:1~5, Zn(Ac) 2 2H 2 The molar ratio of O to the third main group compound is 1:0.01~0.10, Zn(Ac) 2 2H 2 The molar ratio of O to thioacetamide is 1:4.03~12.30; the third main group compound is InCl 3 4H 2 O or GaCl 3 .

specific Embodiment approach 2

[0017] Specific embodiment two: the preparation method of composite photocatalyst of this embodiment realizes according to the following steps: one, weigh Zn (Ac) 2 2H 2 O, Cd(Ac) 2 2H 2 O, the third main group compound and thioacetamide, Zn(Ac) 2 2H 2 O and Cd(Ac) 2 2H 2 The molar ratio of O is 1:1~5, Zn(Ac) 2 2H 2 The molar ratio of O to the third main group compound is 1:0.01~0.1, Zn(Ac) 2 2H 2 The molar ratio of O to thioacetamide is 1:4.03~12.30, and then they are added to 5~20mL of acetone or ethanol solution to form a mixture; 2. Seal the mixture obtained in step 1 and put it into an ultrasonic reactor , react at 40-80°C for 0.5-18h; 3. Cool the product obtained in step 2 to room temperature, wash it with absolute ethanol for 2-5 times, and then dry it in an oven at 50°C for 0.5-5h to obtain Composite photocatalyst; wherein the third main group compound in step 1 is InCl 3 4H 2 O or GaCl 3 .

specific Embodiment approach 3

[0018] Specific embodiment three: the difference between this embodiment and specific embodiment two is that in step one, Zn(Ac) 2 2H 2 O, Cd(Ac) 2 2H 2 O, add the third main group compound and thioacetamide to 7-10mL of acetone or ethanol solution. Others are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com