Preparation method of aminosilane-functionalized graphene reinforced silica gel

An aminosilane and propylaminoethoxysilane technology, applied in the field of graphene material reinforced silica gel, can solve problems such as harsh conditions, and achieve the effects of increased toughness and increased compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

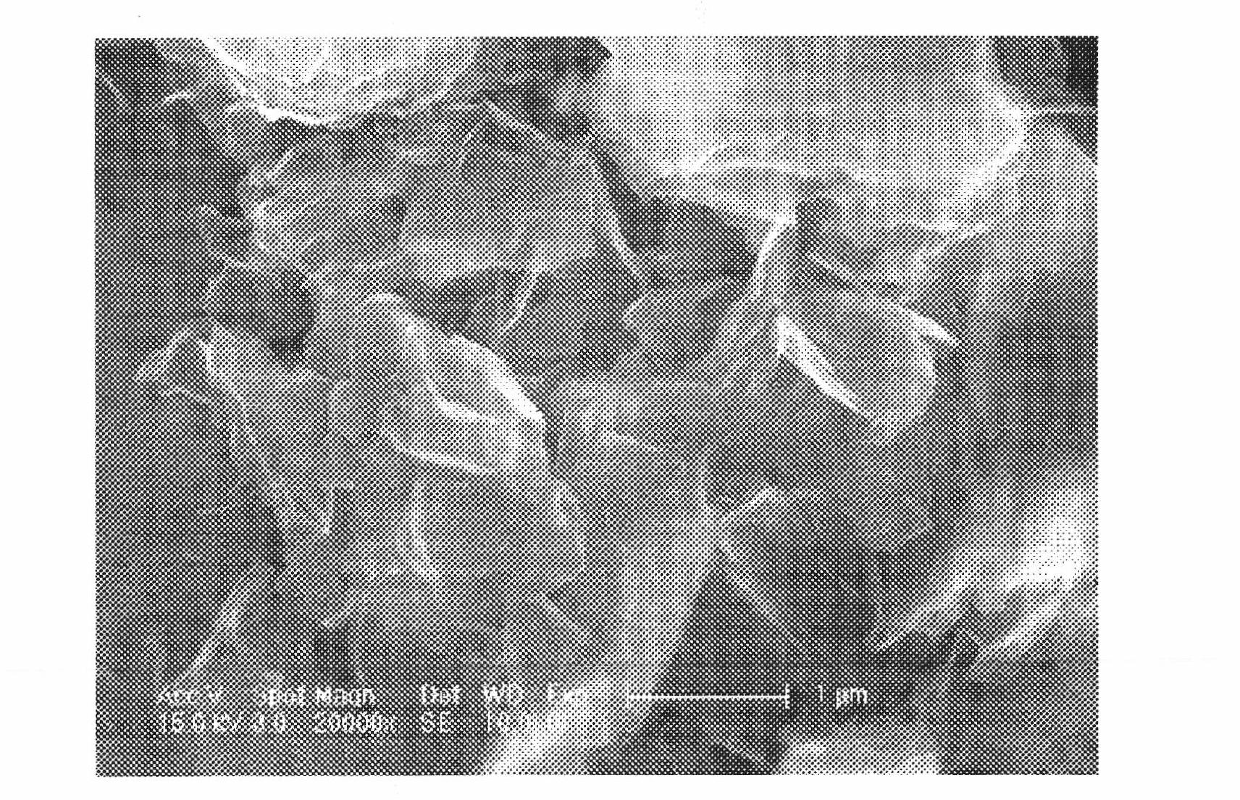

[0021] (1) Preparation of 3-propylaminoethoxysilane functionalized graphene materials

[0022] Add graphene oxide into 3-propylaminoethoxysilane, the dispersion concentration of graphene oxide in 3-propylaminoethoxysilane is 0.5 mg / mL, and reflux reaction at 70°C for 24 hours to obtain Black uniform dispersion, filter the black dispersion with a 0.22 μm nylon filter, wash thoroughly with absolute ethanol, and then disperse in absolute ethanol. The dispersion was filtered through a 0.22 μm nylon filter membrane, washed with absolute ethanol, and dried in a vacuum oven at 30° C. for 24 hours to obtain a graphene material functionalized with 3-propylaminoethoxysilane.

[0023] (2) Preparation of 3-propylaminoethoxysilane functionalized graphene material reinforced silica gel

[0024] The graphene material of the 3-propylaminoethoxysilane functionalization that step (1) obtains is added in the 3-propylaminoethoxysilane, and the graphene material of the 3-propylaminoethoxysilane f...

Embodiment 2

[0026] Use 3-propylaminomethoxysilane, N-aminoethyl-3-aminopropyltrimethoxysilane, N-aminoethyl-3-aminopropylmethyldiethoxysilane or N-aminoethyl -3-aminopropyltriethoxysilane replaces 3-propylaminoethoxysilane, and the rest are the same as in Example 1.

Embodiment 3

[0028] (1) Preparation of 3-propylaminoethoxysilane functionalized graphene materials

[0029] Add graphene oxide into 3-propylaminoethoxysilane, the dispersion concentration of graphene oxide in 3-propylaminoethoxysilane is 0.1mg / mL, and reflux reaction at 70°C for 24 hours to obtain Black uniform dispersion, filter the black dispersion with a 0.22 μm nylon filter, wash thoroughly with absolute ethanol, and then disperse in absolute ethanol. The dispersion was filtered through a 0.22 μm nylon filter membrane, washed with absolute ethanol, and dried in a vacuum oven at 30° C. for 24 hours to obtain a graphene material functionalized with 3-propylaminoethoxysilane.

[0030] (2) Preparation of 3-propylaminoethoxysilane functionalized graphene material reinforced silica gel

[0031] The graphene material of the 3-propylaminoethoxysilane functionalization that step (1) obtains is added in the 3-propylaminoethoxysilane, and the graphene material of the 3-propylaminoethoxysilane fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com