Omnibearing multi-duct energy-saving hot blast producing furnace

A technology of hot blast generator and multiple air ducts, which is applied to heating devices, air heaters, fluid heaters, etc., can solve the problems of short combustion fire path, large furnace space, and large energy consumption, and achieve high heat energy recovery and utilization rate , Large heating area of the air duct and reasonable structure of the air duct

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

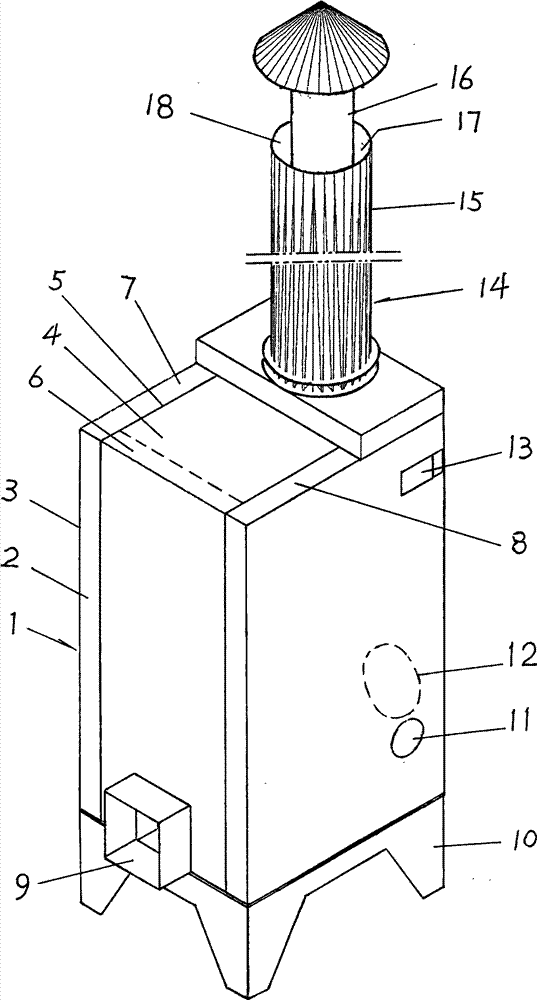

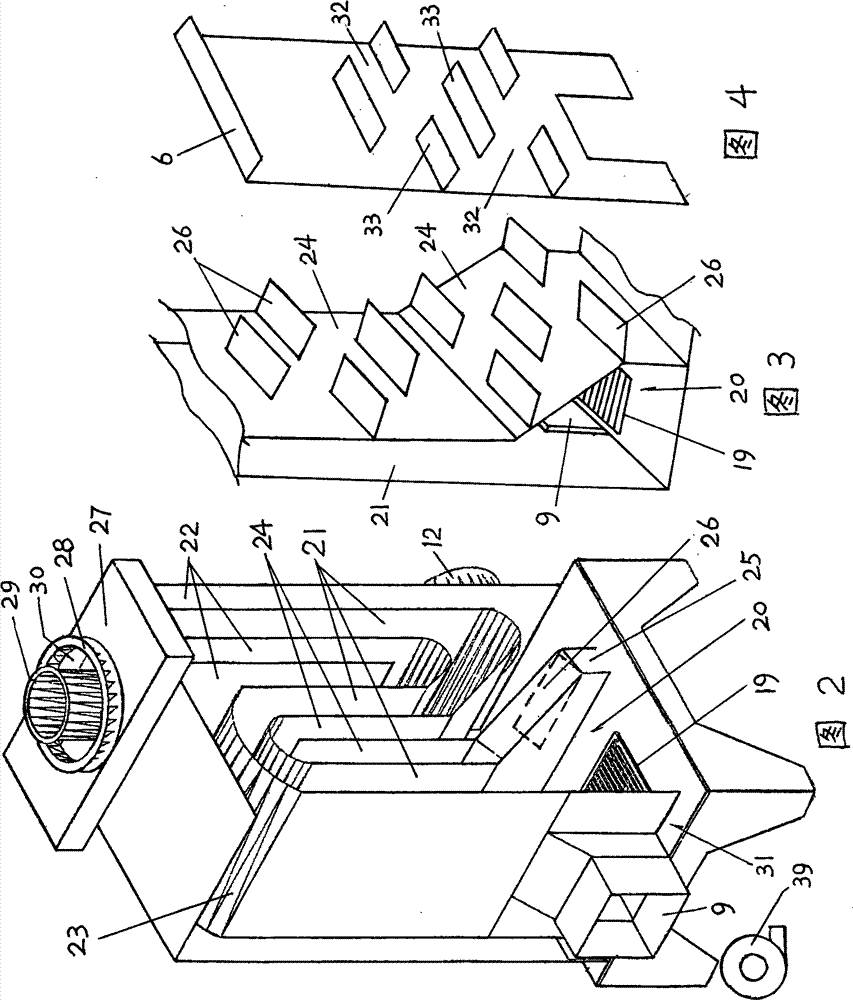

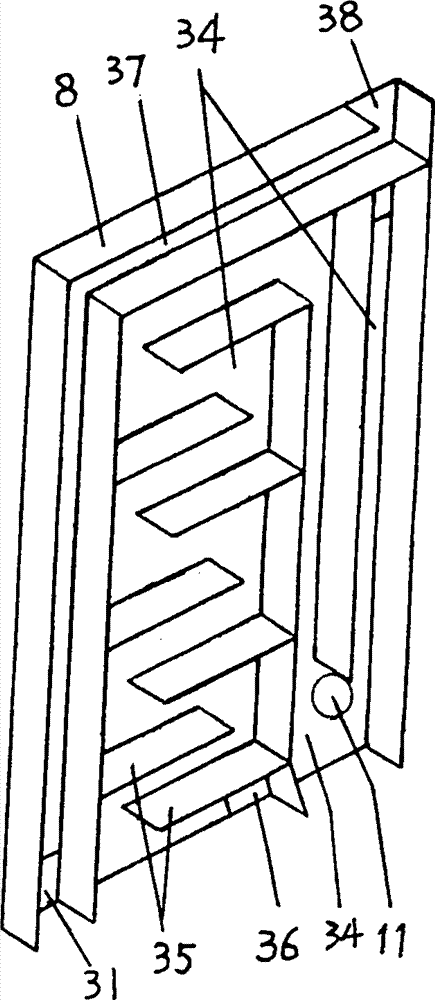

[0026]With reference to the accompanying drawings, it can be seen that the overall structure of this all-round multi-channel energy-saving hot blast generator of the present invention is composed of the following components: 1--furnace body, 2--outer furnace body (also known as the attached furnace body part), 3 -- the outer furnace wall of the outer furnace body (also known as the attached furnace wall), 4 -- the inner furnace body (also known as the main furnace body part), 5 -- the inner furnace wall of the inner furnace body (also known as the main furnace wall), 6--Front chamber (forming the heat-absorbing air passage of the front chamber), 7--Left chamber (forming the heat-absorbing air passage of the left chamber), 8--Right chamber (forming the heat-absorbing air passage of the right chamber), 9 --Stove mouth (stove burner mouth), 10--furnace base, 11-side chamber dust removal port located at the bottom of the serpentine fire path, 12-hot air outlet, 13-side chamber air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com