Program-control method for temperature control in quick flash annealing furnace

A technology of control area and furnace cavity, which is applied in the direction of temperature control, furnace control device, furnace, etc. using electric mode, can solve the problem of inability to realize rapid heat treatment function, etc., and achieves high integration, high adjustment accuracy, and simple control circuit. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

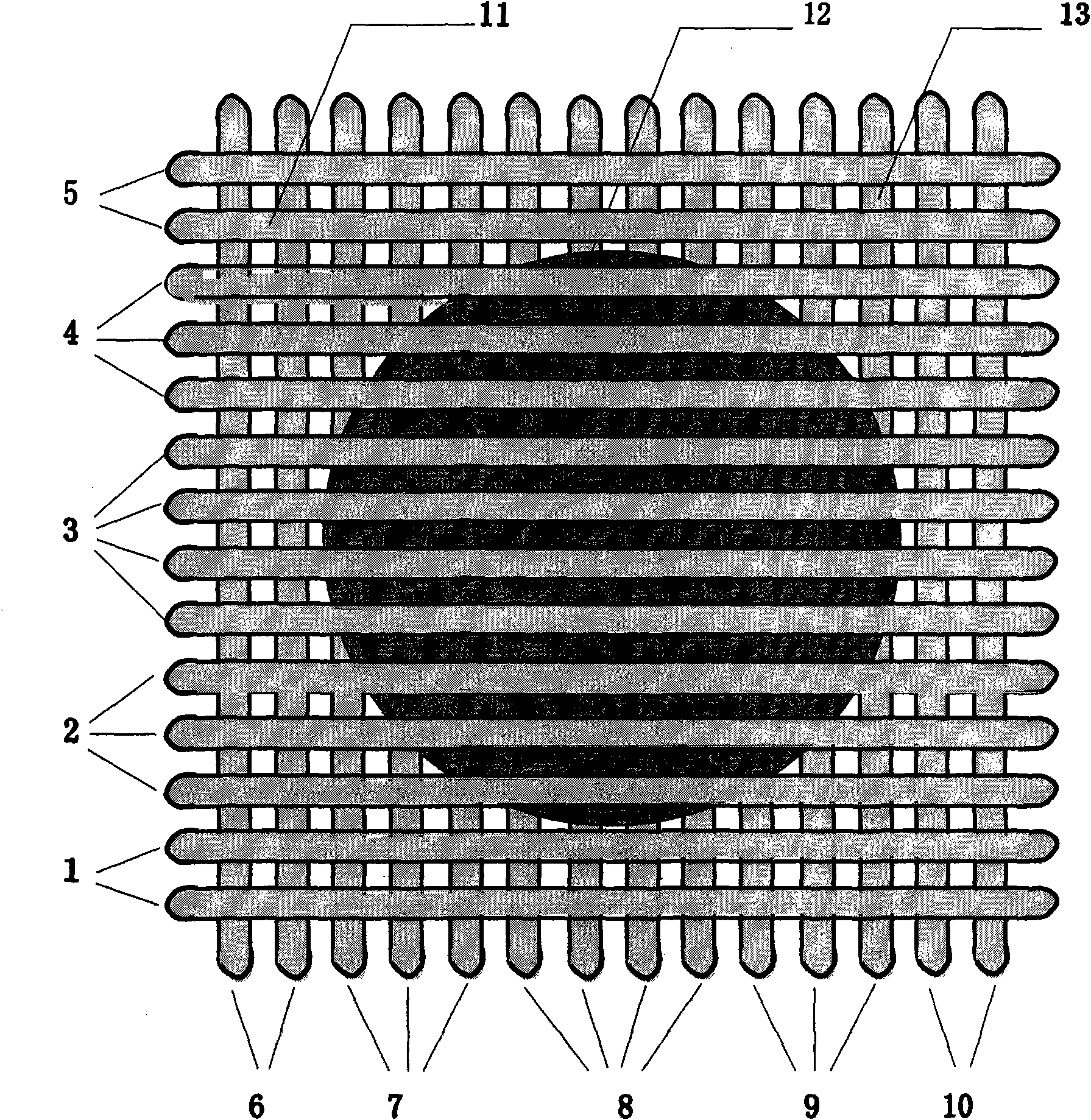

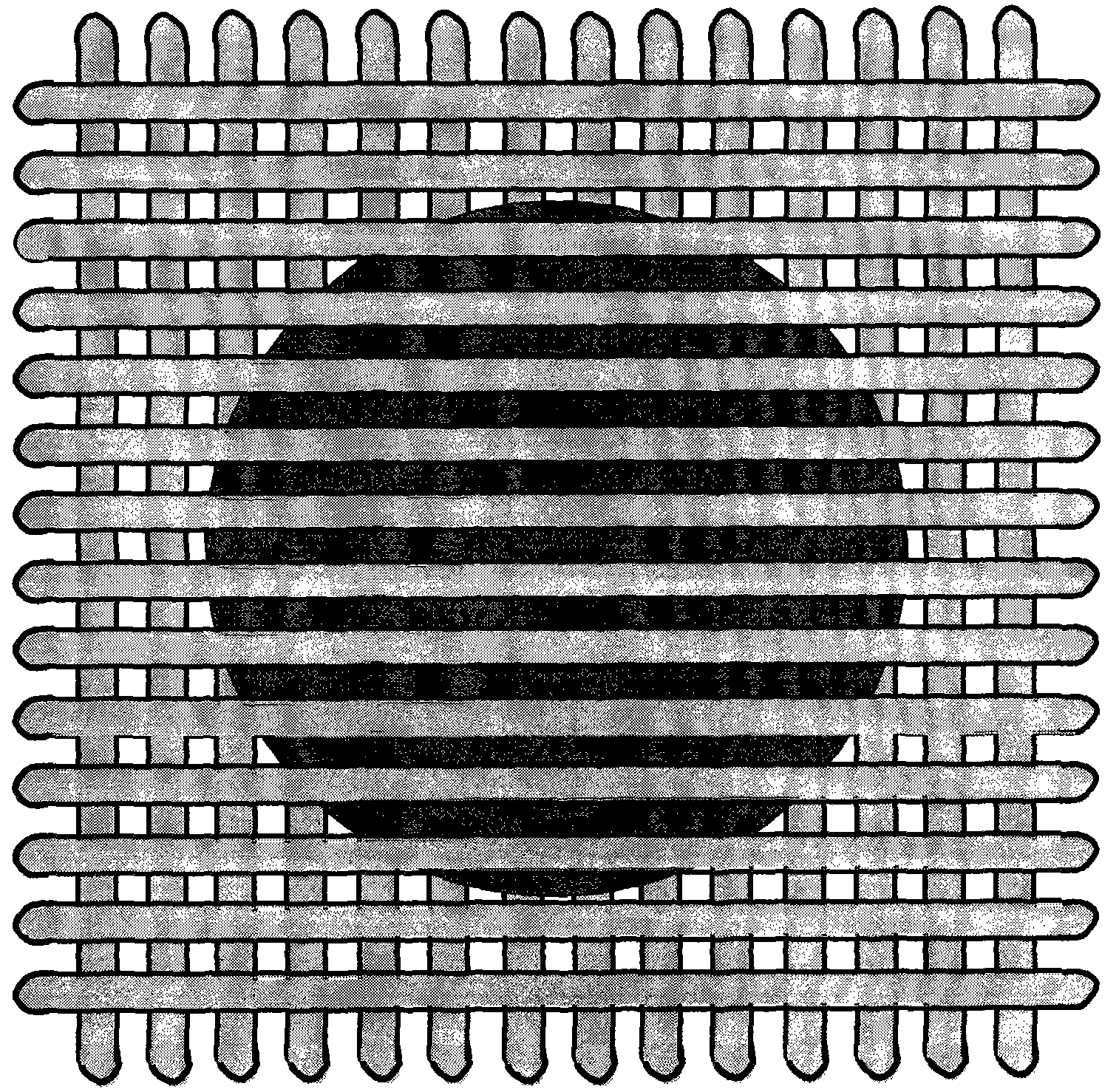

[0016] see figure 1 , the lamp tube layout of the rapid flash annealing furnace is described as follows: 1 is control area 1; 2 is control area 2; 3 is control area 3; 4 is control area 4; 5 is control area 5; 6 is control area 6; Control area 7; 8 is control area 8; 9 is control area 9; 10 is control area 10; 11 is the top lamp group; 12 is the silicon wafer; 13 is the bottom lamp group.

[0017] The heating of the silicon wafer adopts the halogen tungsten lamp radiation heating method. A total of 28 halogen lamp tubes of 1.5KW and 2KW specifications are used, which are respectively installed on the top and bottom of the furnace cavity, and each has 14 lamp tubes. The lamp tubes at the bottom are arranged in a vertical cross shape. The 28 lamp tubes are divided into 10 heating power control areas, and 5 heating power control areas are distributed on the top and bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com