Method and device for simultaneously measuring droplet position, particle sizes and complex refractive index

A complex refractive index, particle size technique, applied in the direction of measuring devices, using optical devices, particle and sedimentation analysis, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

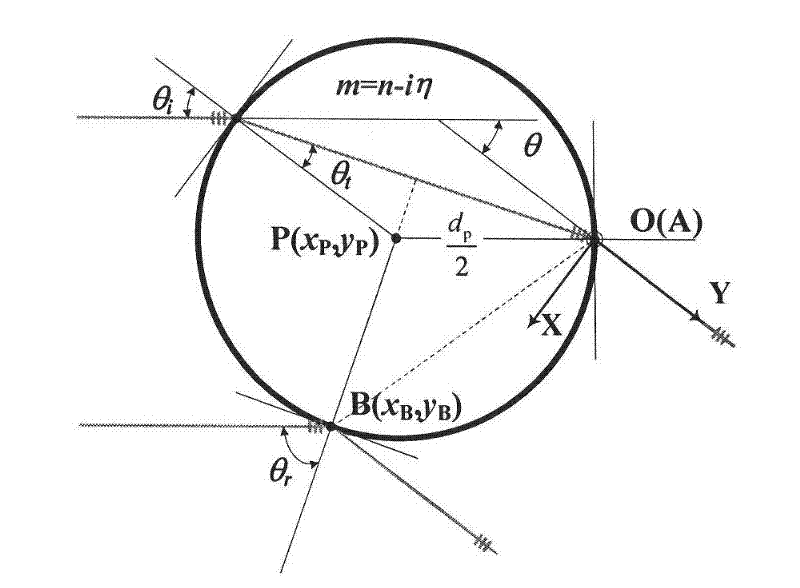

[0046] Referring to the accompanying drawings, the implementation method of the present invention will be described in detail below.

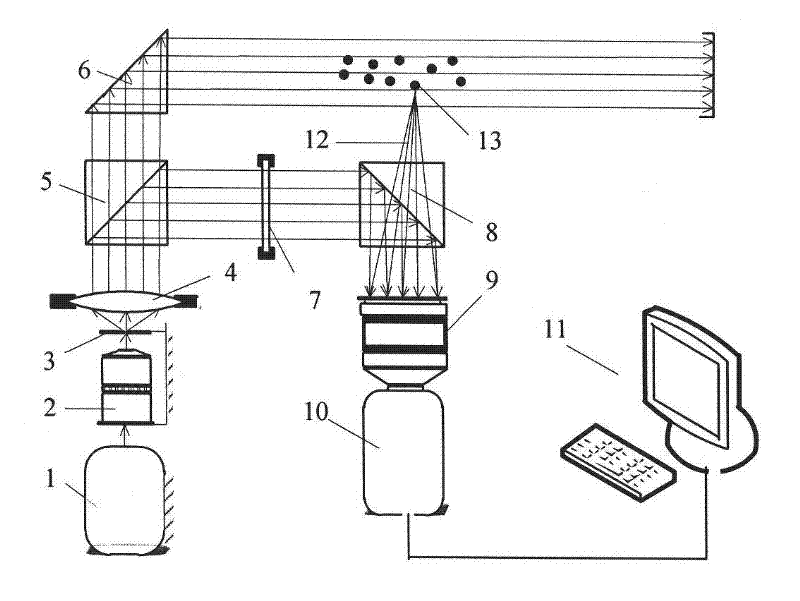

[0047] Among the present invention, be used for realizing the device of simultaneously measuring droplet particle position, particle size and complex refractive index method, comprise highly coherent laser 1, the spatial filter that microscopic objective lens 2 and pinhole diaphragm 3 are formed, beam expander lens ( Collimating beam expander) 4, beam splitter 5, total reflection mirror 6, light intensity attenuator 7, mixing mirror 8, industrial microscope lens 9, CCD camera 10, hologram processor and processing software 11.

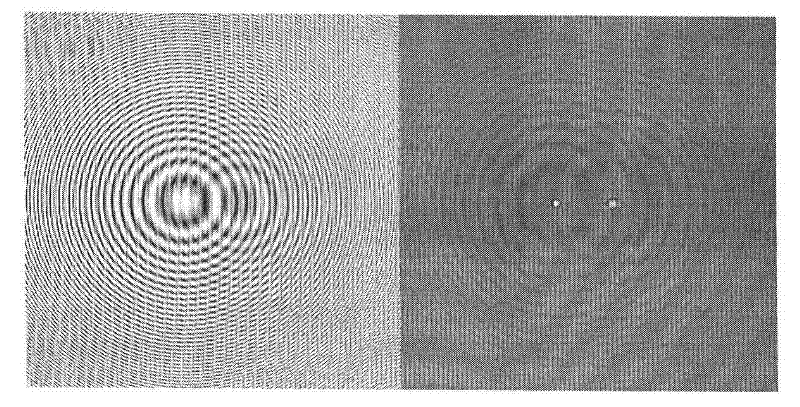

[0048] Such as figure 1 As shown, the laser light emitted by laser 1 (the coherence length is required to be more than 10cm) is converged by a microscope objective lens (10X-50X), and a pinhole diaphragm 3 (aperture 5μm-100μm) is placed at its focus to achieve low-pass filtering, and then The collimated beam expansion i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com