Photon sieve phase contrast objective lens, manufacturing method and imaging method

A manufacturing method and photon sieve technology, applied in the field of objective lenses, can solve the problems of blurred image details, difficult precise alignment, and low image contrast, and achieve the effects of high imaging resolution and imaging contrast, precise alignment, and simple system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The above-mentioned photon sieve phase contrast objective lens will be further described below mainly in conjunction with the accompanying drawings and specific embodiments.

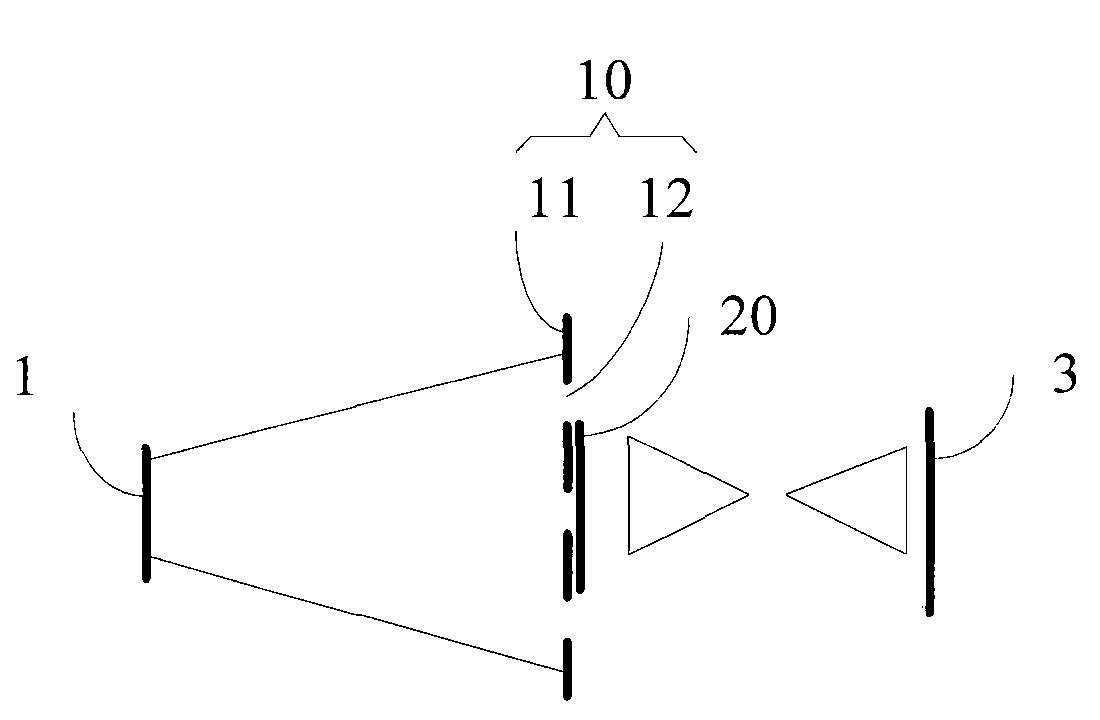

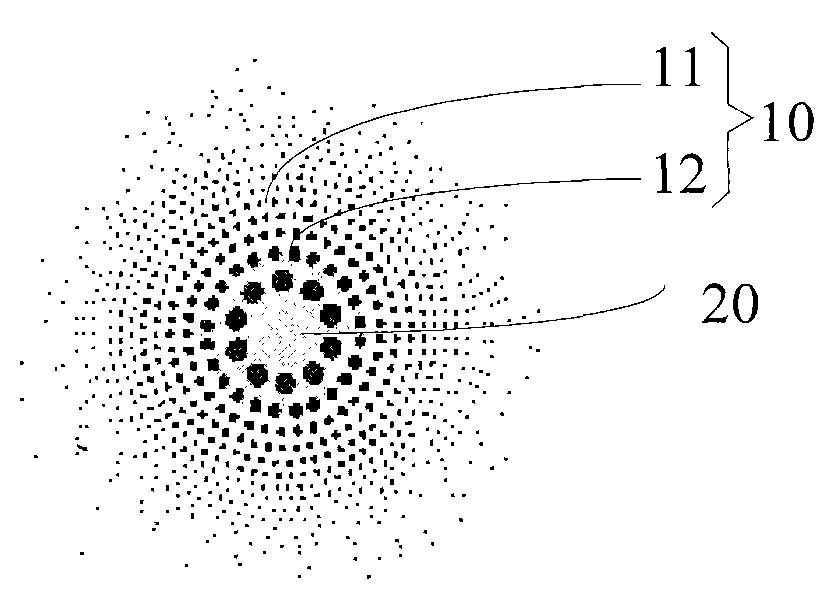

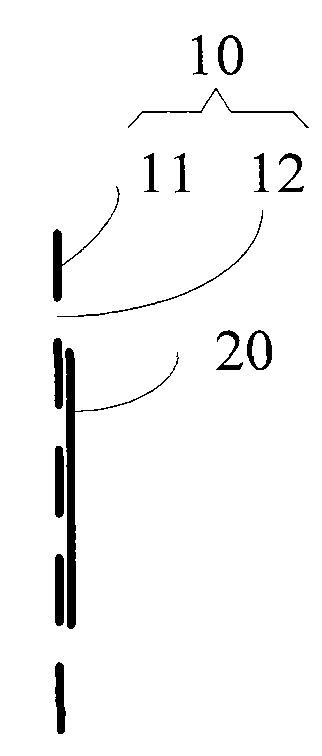

[0036] figure 1 Schematic diagram of photon sieve phase-contrast microscopy. In one embodiment, the photon sieve phase contrast objective lens includes a photon sieve lens 10 and a phase changing plate 20 disposed on the surface of the photon sieve lens 10 . The photon sieve lens 10 is formed by a base 11 and a plurality of light-transmitting holes 12 disposed on the base 11 . The phase changing plate 20 is located in the middle of the photon sieve lens 10 or surrounds the edge of the photon sieve lens 10 , and the center of the phase changing plate 20 and the center of the photon sieve lens 10 are on the same axis. In this way, the phase changing plate 20 and the photon sieve lens 10 are closely combined. A part of the light irradiated on the object to be tested forms off-axis diffracted light...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com