Four-slider zoom compensation mechanism of zoom lens

A technology of zooming and sliding rods, applied in installation, optics, instruments, etc., can solve the problems of optical structure design limitations, inability to design zoom and compensation structures, etc., and achieve the effect of reducing processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

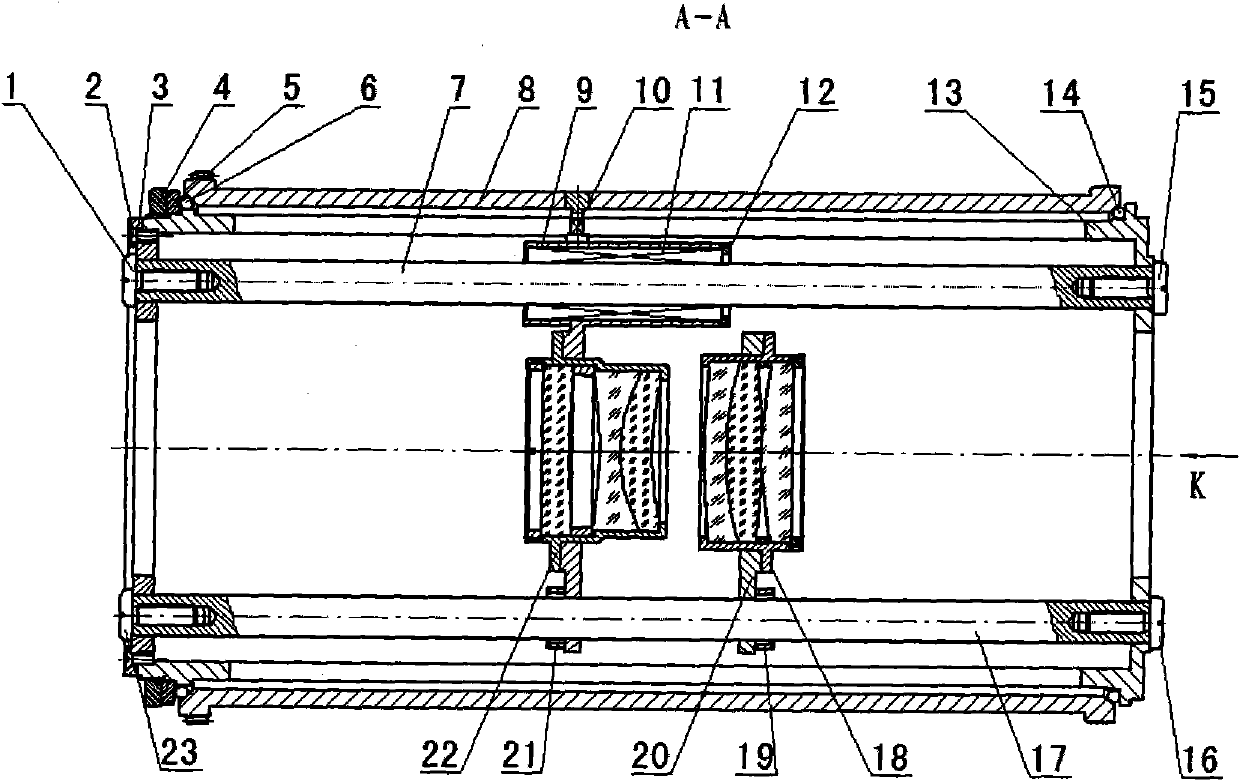

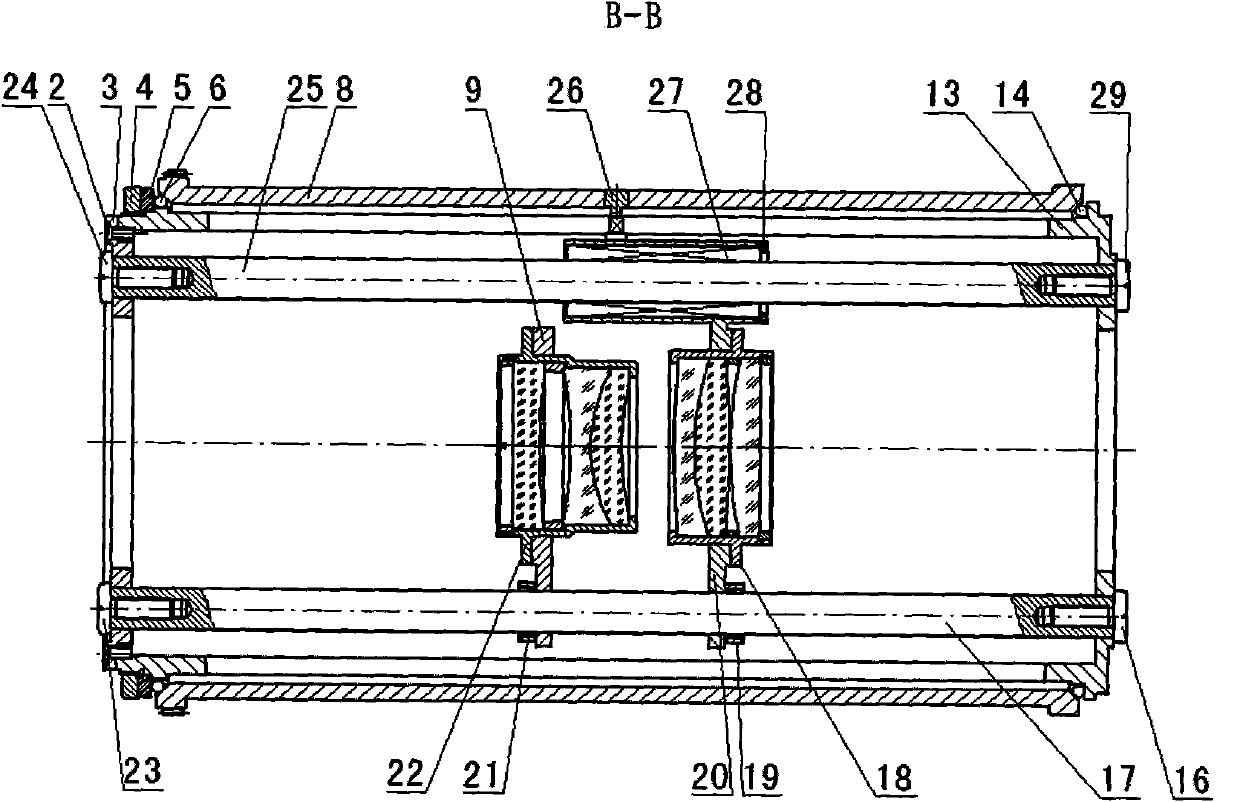

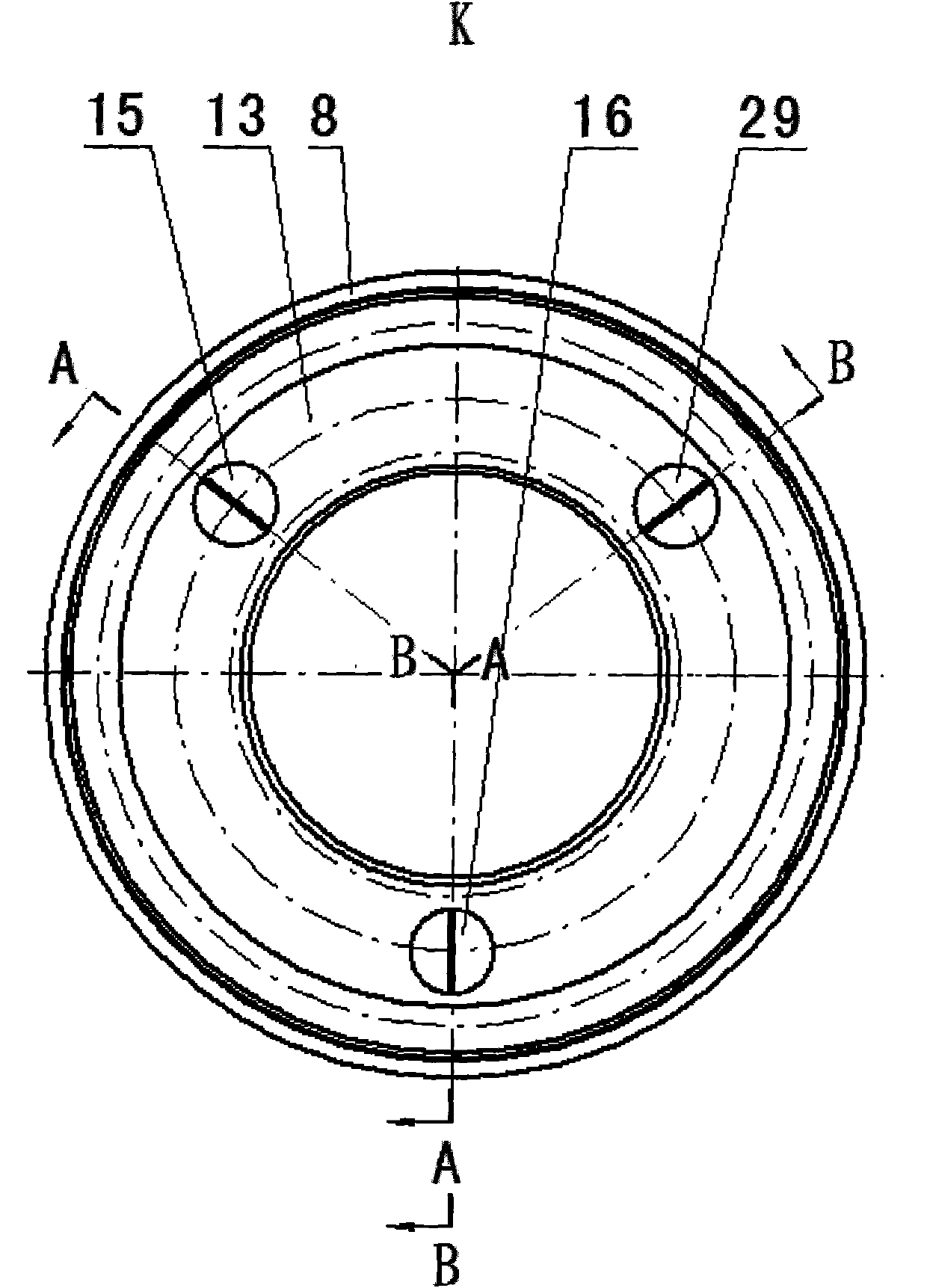

[0020] The invention according to Figure 4 , Figure 5 , Figure 6The structure shown is implemented. Wherein the left bearing stop ring 35, the first steel ball 36, the first slide bar 37, the cam 38, the lens barrel 43, the second steel ball 44, the second slide bar 49, the third slide bar 50, and the fourth slide bar 60 adopt GCr15 steel material; the first slider left screw 30, the first washer 31, the first screw 32, the cover plate 33, the left adjustment nut 34, the left bearing stop ring 35, the zoom carriage 39, the zoom guide shaft 40, the first A zoom bearing pressure ring 42, a second washer 45, a right screw 46 of the first slide bar, a right screw 47 of a second slide bar, a right screw 48 of a third slide bar, a compensation carriage 52, a second zoom bearing press ring 53 , The third slide bar left screw 56, the second slide bar left screw 57, the fourth slide bar left screw 58, the third washer 59, the compensation guide shaft 61, the first compensation be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com