Optical structure of LED liquid crystal projector with single polarization converter

A polarization converter and optical structure technology, applied in optics, optical components, instruments, etc., can solve problems such as difficult to borrow, micro projectors that have not been seen, and large LED light-emitting area, so as to achieve simple processing and assembly, and improve Effect of light energy utilization efficiency and brightness, small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

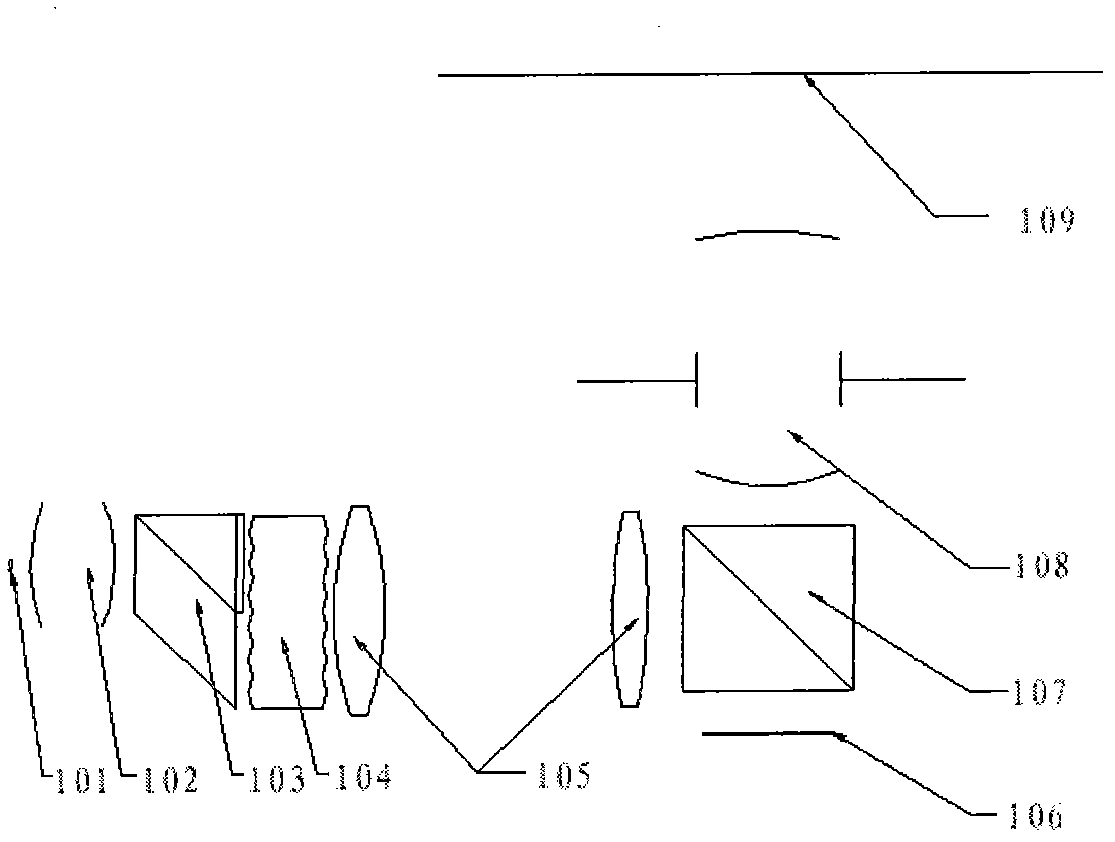

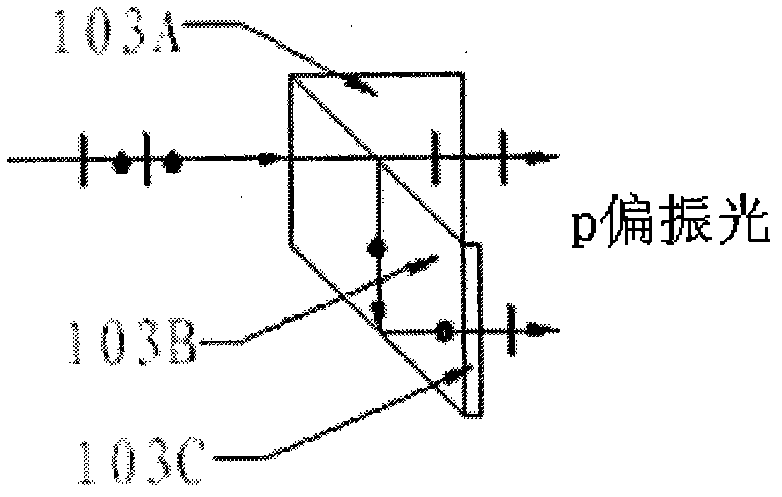

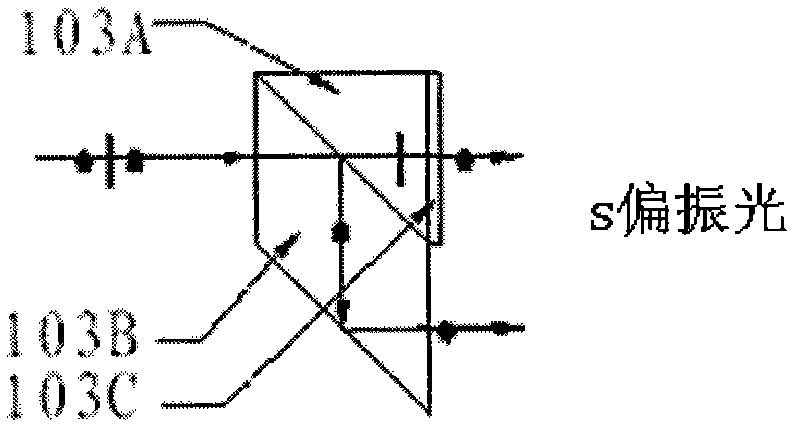

[0022] refer to figure 1 , the optical structure of the LED liquid crystal projector with a single polarization converter in Scheme 1, including the illumination optical axis and the imaging optical axis, and the light source LED 101, the collimating mirror 102, and the single transmissive polarization converter 103 are placed in sequence on the illumination optical axis , lens array 104 and relay optical group 105, place LCOS liquid crystal screen 106, PBS (polarizing beam splitter) 107 and projection lens 108 successively on the imaging optical axis, the illumination optical axis is perpendicular to imaging optical axis; After the light is collimated by the collimating mirror 102, it enters a single transmissive polarization converter 103, and the unpolarized light is converted into polarized light by the single transmissive polarization converter 103, and then enters the lens array 104, and the beam is shaped by the lens array 104 Afterwards, the relay light group 105 reach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com