Device for real-time monitoring of mixing material ratio data in asphalt mixing station

A real-time data monitoring and mixing plant technology, applied in the direction of program control, computer control, general control system, etc., can solve the problem that the asphalt mixture detection method cannot meet the requirements of real-time monitoring, the printing data of the asphalt mixing plant cannot fully play its role, and the asphalt Problems such as the difficulty of online real-time monitoring of the mixing quality of the mixture, to achieve the effect of improving and maintaining the interests of the enterprise, increasing the risk of the system, and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

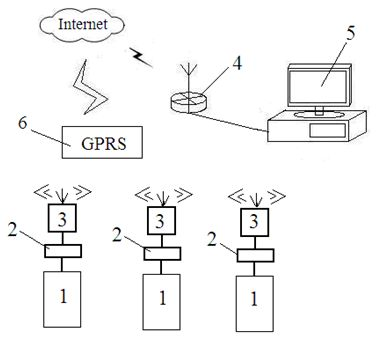

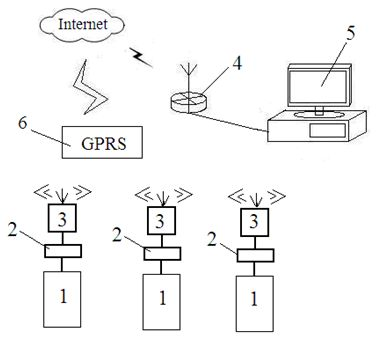

[0024] see figure 1 and figure 2 , the real-time data monitoring device of the asphalt mixing station mixing ratio of the present invention comprises the industrial control computer 1 in the operation room of each mixing station, and a VGA high-definition image acquisition card is installed on the industrial control computer 1 in the operation room of each mixing station 2. The VGA high-definition image acquisition card is connected to the wireless module 3 through the RS232 bus serial port. The wireless module 3 and the GPRS module 6 form a GPRS wireless network. The GPRS wireless network is connected to the monitoring center computer 5 through the Internct network and the router 4 . Remote monitoring software is housed in the monitoring center computer 5 .

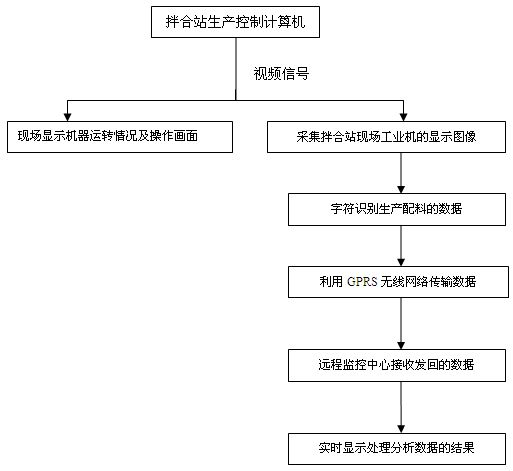

[0025] The working process of the device is:

[0026] Use the VGA high-definition image acquisition card to collect the images of the interface in the assigned on-site industrial control asphalt mixing plant.

[0027...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com