Semiconductor laser device

A laser device and semiconductor technology, which is applied in the direction of semiconductor laser devices, semiconductor lasers, laser devices, etc., can solve the problem of not being able to sufficiently reduce the angle deviation of the polarization direction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

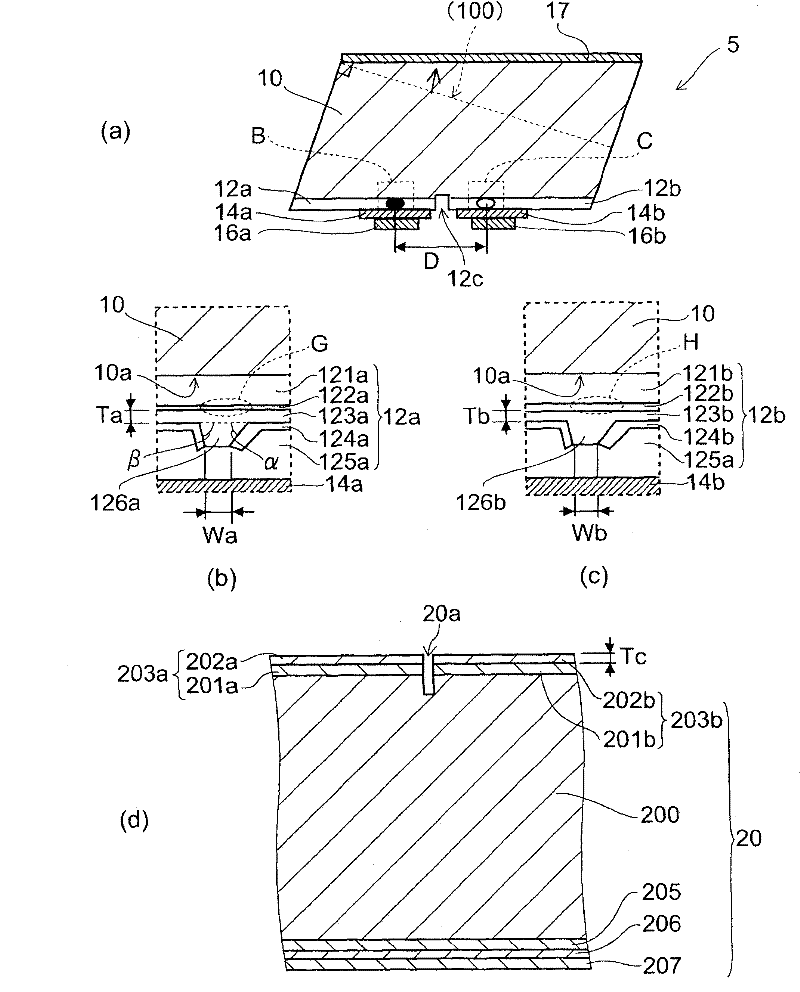

[0024] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

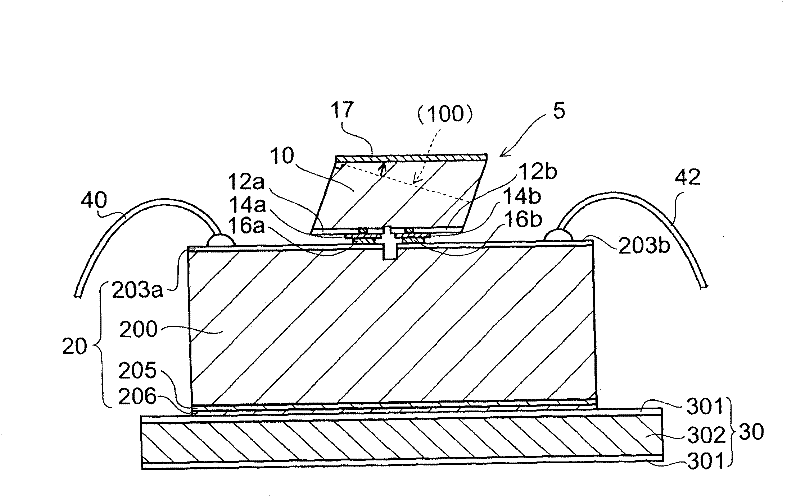

[0025] figure 1 is a schematic cross-sectional view of a semiconductor laser device according to an embodiment of the present invention.

[0026] The semiconductor laser device includes: a laser array 5 , a base 20 , alloy solder layers 16 , 207 and leads 30 .

[0027] The laser array 5 has, on a semiconductor substrate 10 made of n-type GaAs or the like: a first stack 12a including a light-emitting layer, a second stack 12b including a light-emitting layer, and a first p-layer provided on the first stack 12a. The side electrode 14a, and the second p-side electrode 14b provided on the second laminated body 12b.

[0028] The base 20 has first and second conductive layers 203a, 203b on one face of the insulating material 200 . In addition, the base 20 has a backside conductive layer on the other side of the insulating material 200 . The first conductive layer 203a is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com