H-bridge driving control circuit of motor

A technology of drive control circuit and drive unit, which is applied in the direction of starter, excitation or armature current control, motor generator/starter, etc. of a single DC motor, and can solve the problem of no anti-interference measures, weak anti-electromagnetic interference, Field effect tube misconduct and other problems, to improve the anti-interference ability, ensure reliable work, and easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing, preferred specific embodiment of the present invention is described:

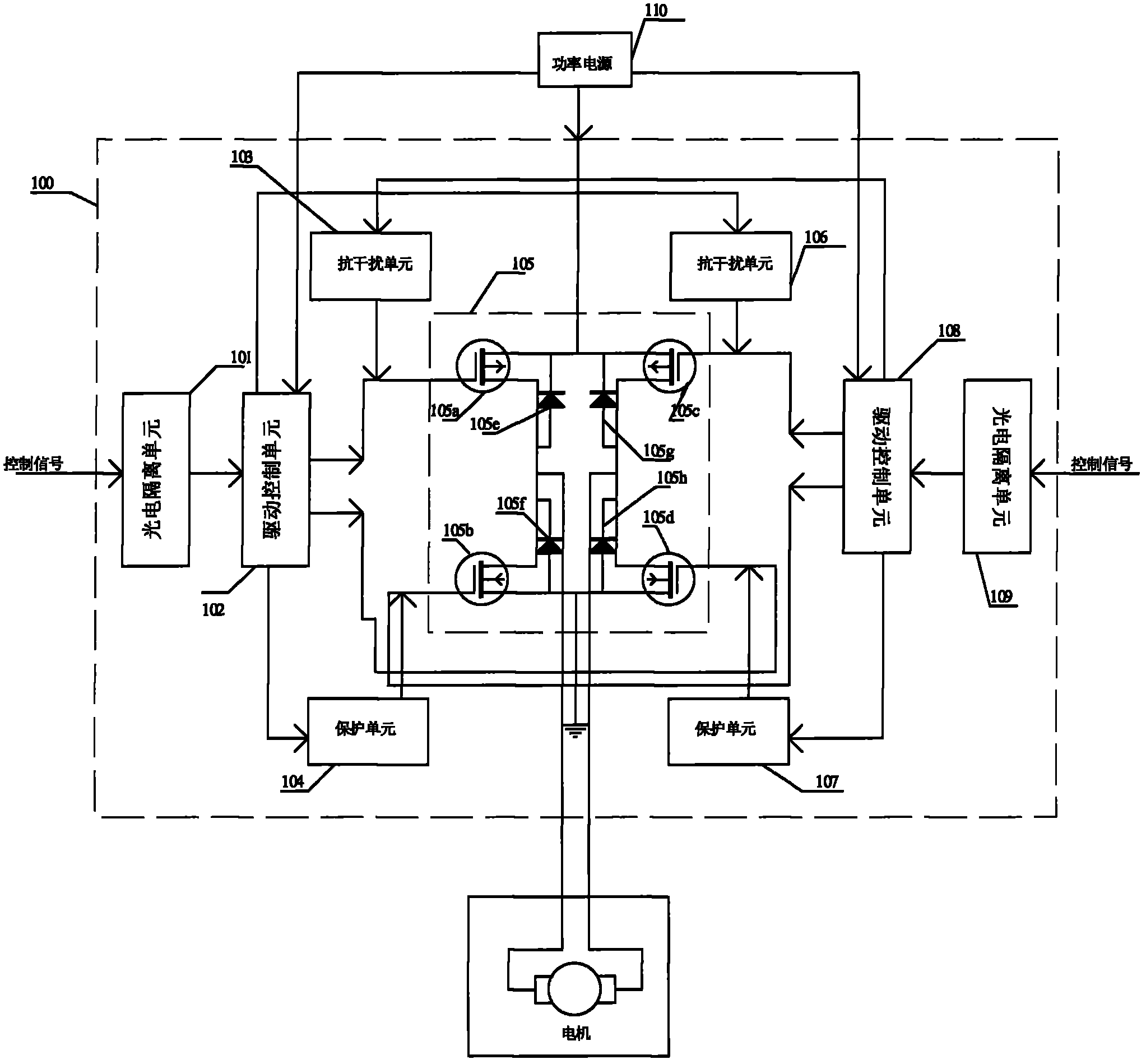

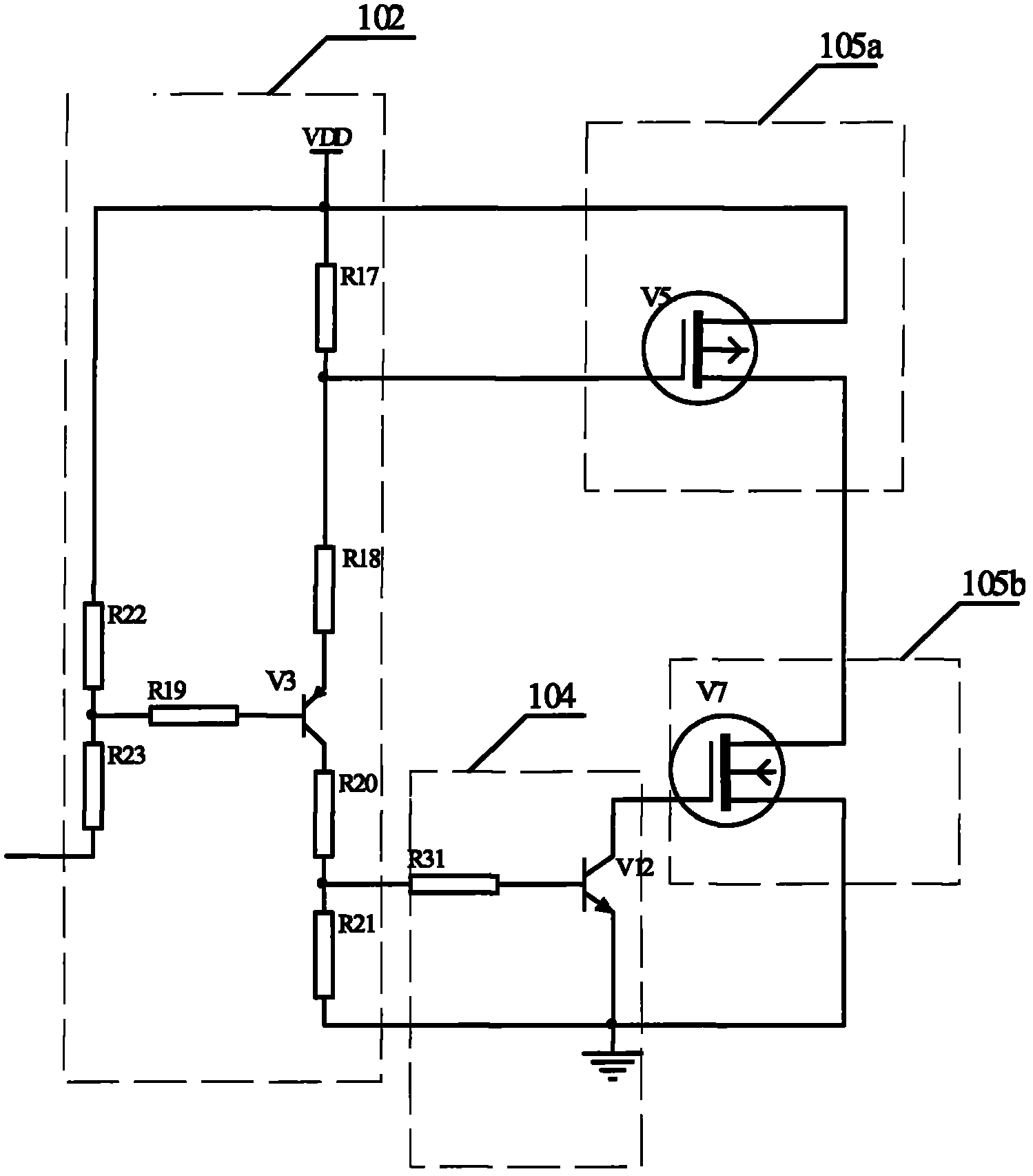

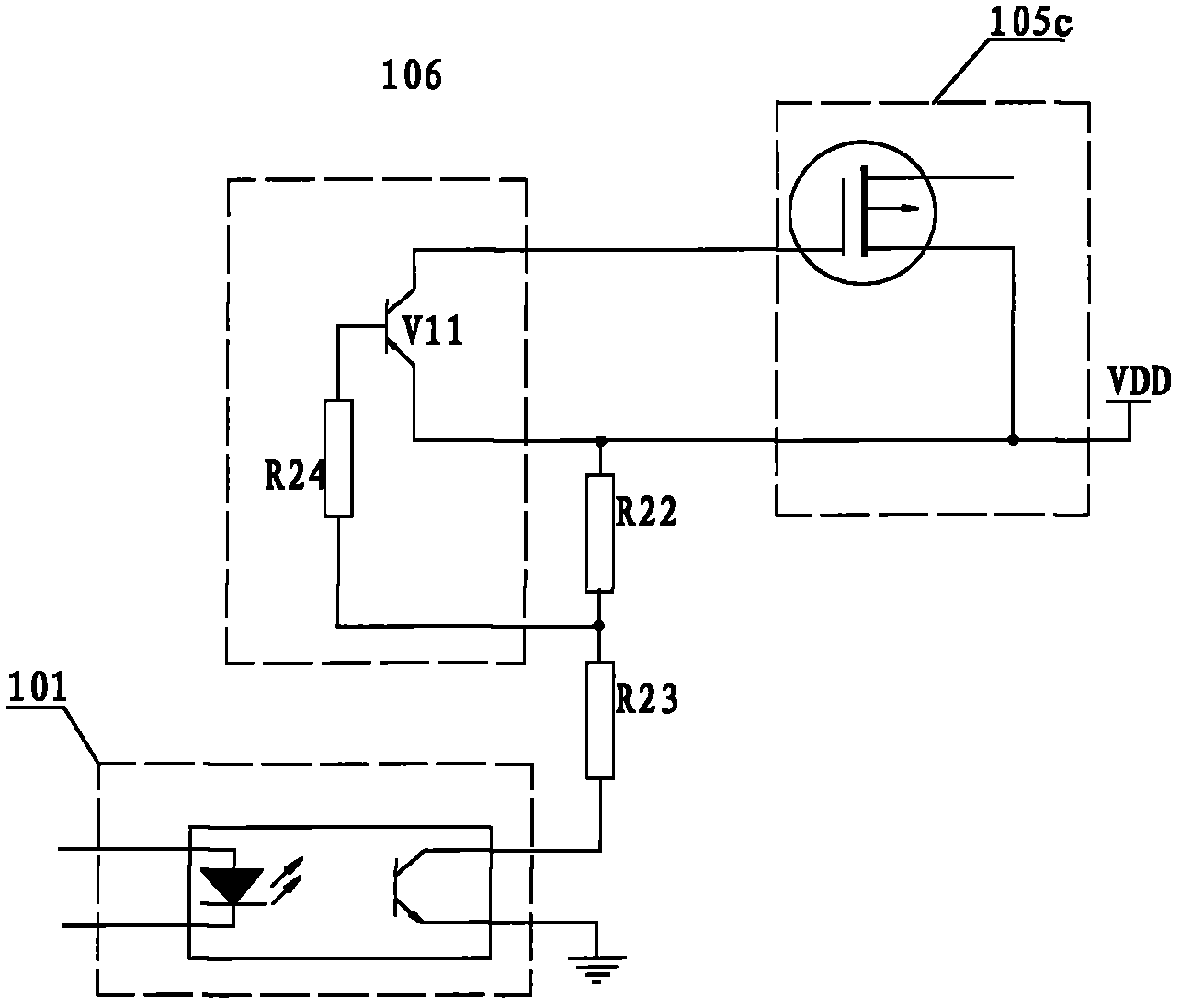

[0027] Such as figure 1 The H bridge drive control circuit shown is mainly composed of core H bridge drive unit 105, drive control units 102 and 108, anti-interference units 103 and 106, protection units 104 and 107, photoelectric isolation units 101 and 108 and the same power supply 110 constitute. Wherein, the H-bridge driving unit 105 is mainly composed of four field effect transistors, and the four field effect transistors include two P-channel field effect transistors 105a and 105c located on the upper arm and two N-channel field effect transistors 105b and 105d located on the lower arm . Wherein, the field effect transistor 105a of the left upper arm and the field effect transistor 105d of the right lower arm constitute branch one, and the field effect transistor 105c of the right upper arm and the field effect transistor 105b of the left lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com