A device and method for transport heat

A heat and heat exchanger technology, applied in the field of heat generation, can solve problems such as poor adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

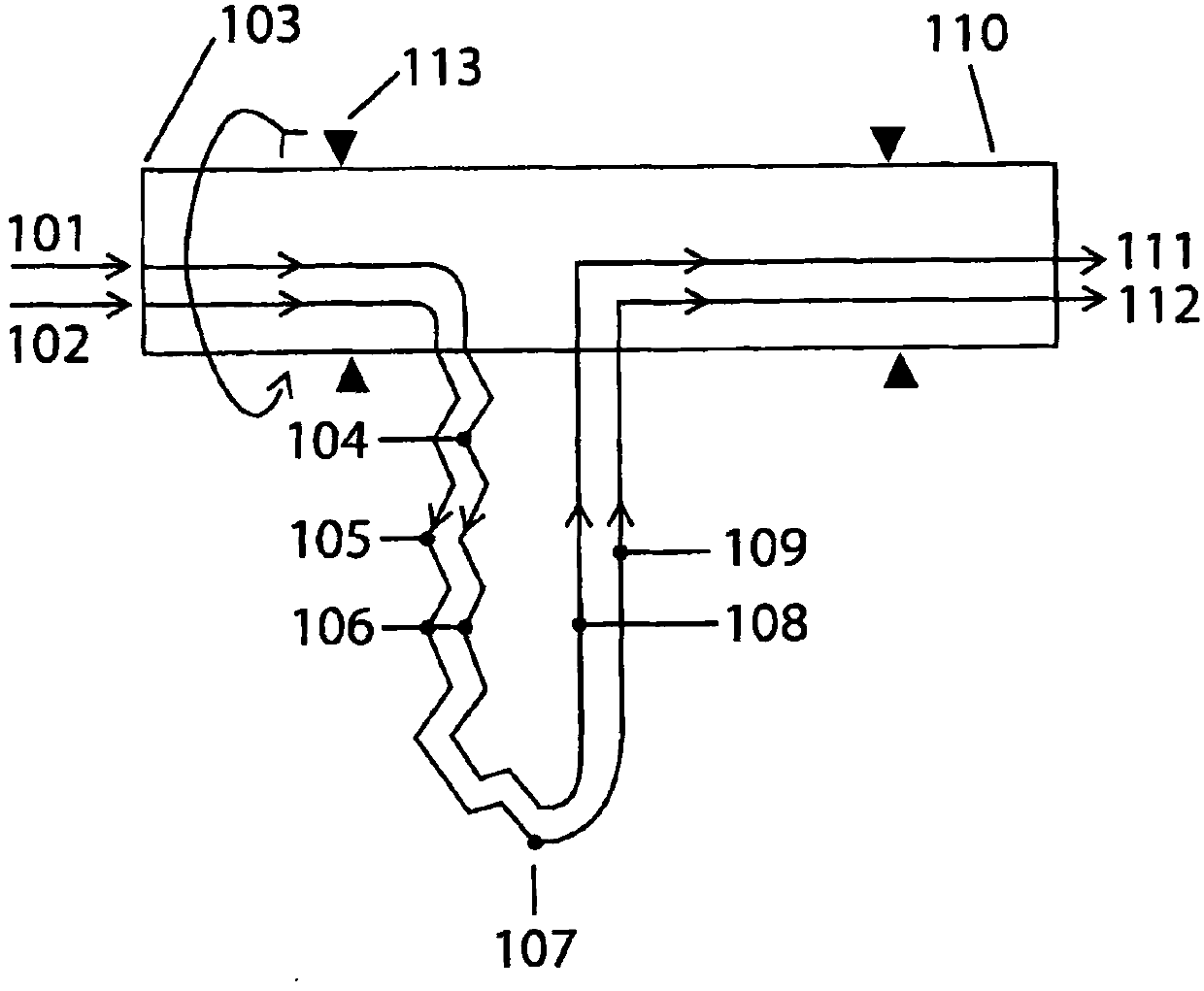

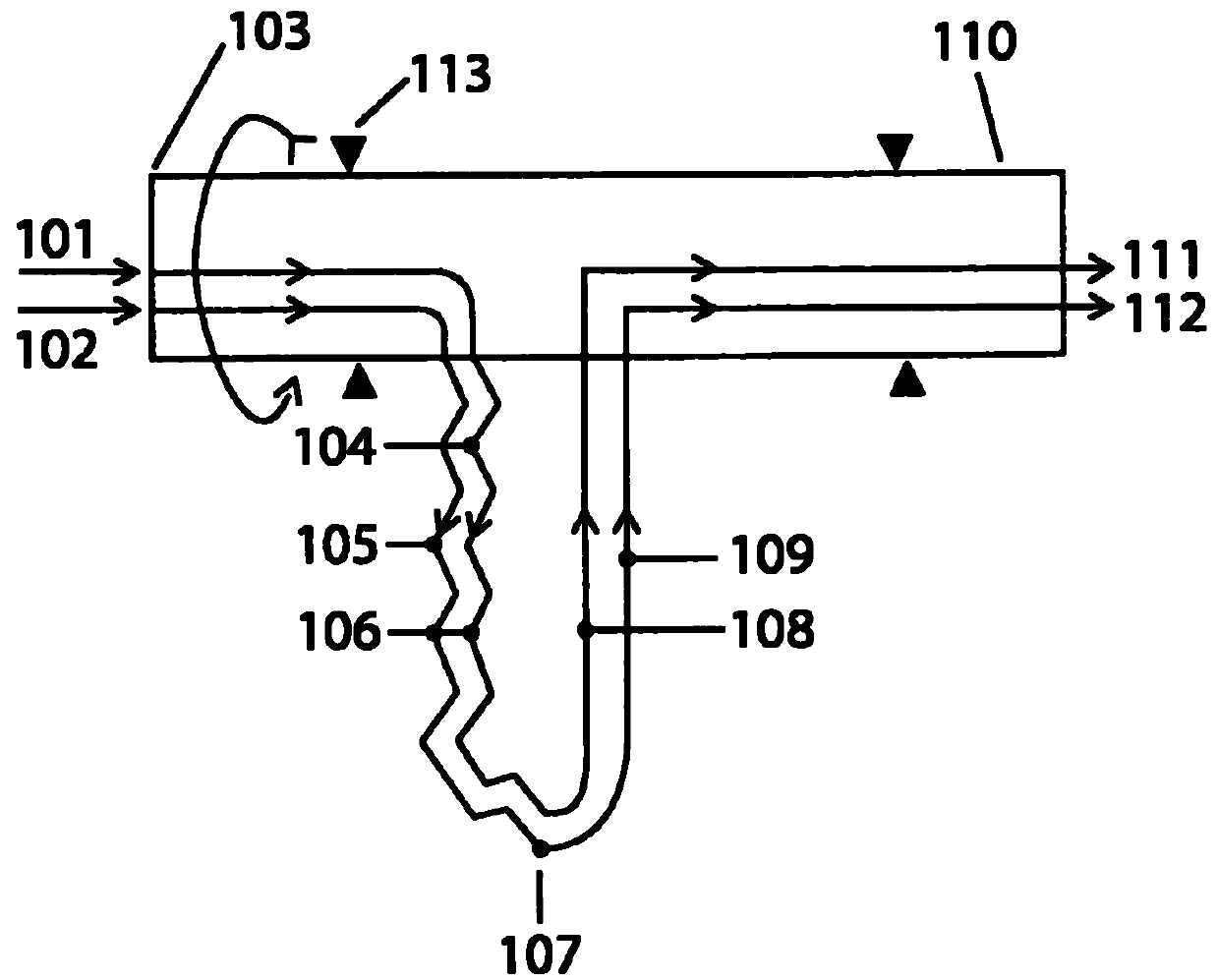

Image

Examples

example 1

[0046] Example 1: The following calculation shows an example of the theoretical temperature of hydrogen and argon in a closed system with heat exchange at the periphery, and the peripheral velocity (vp) is 400m / s. 1 = entrance, 2 = periphery, 3 = exit. Since the flow rate in the fluid channel can be relatively low, the resistance, pressure, and temperature drop are in a small percentage, so they can be ignored.

[0047] T1-2=ΔT3-2 has the same cp (cp=heat capacity under constant pressure)

[0048] vp=400m / s, cp h2=14320J / kg K, cpAr=520J / kg K

[0049] ΔT h2(1-2)=vp 2 / (2×cp)=400 2 / m / s / (2×14320J / kgK)= 5.6K

[0050] ΔT Ar(1-2)=vp 2 / (2×cp)=400 2 / m / s / (2×520J / kgK)= 154K

[0051] Under the same quality cp, the maximum heat exchange T is equal to:

[0052] T=(((ΔAr-(ΔT h2×cp masse Ar) / (cp masse h2))) / 2=(154K-5.6K) / 2= 74.2K

[0053] This means h 2 The heat exchanger on one shaft end can provide 74.2K higher than the ambient temperature, while on the other shaft end, the argon gas is provided ...

example 2

[0054] Example 2: By using air as a heating fluid in an open system such as a heat exchanger, and using argon as a pressurized cooling fluid in a closed circuit, double the mass cp in the heat exchanger 106 = (1000×2kJ / kgK) / (520kJK)= 3.85 .

[0055] vp=400m / s, cp luft=1000J / kg K, cpAr=520J / kg K

[0056] ΔT Ar(1-2)=vp 2 / (2×cp)=400 2 / m / s / (2×520J / kgK)= 154K

[0057] ΔAir(1-2)=vp 2 / (2×cp)=400 2 / m / s / (2×1000J / kgK)= 80K

[0058] ±ΔT=(((ΔAr-(ΔT luff×cp mass air) / cp mass Ar)))) / 2

[0059] ±ΔT=(((154K-(80K×1000J / kgK) / 3.85×520J / kgK))) / 2= 57K

[0060] This means that at the outlet of the heat exchanger, the air is 57K higher than the ambient temperature, while the argon is 57K colder than the ambient temperature. The air must be pressurized and supplied to the periphery for heating.

[0061] But if the air under constant pressure is cooled by argon at the outlet or outside the outlet through its heat exchanger, both the air and argon will have a T slightly higher than the ambient temperature, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com