Directing sound field of actuator

一种驱动器、静电驱动器的技术,应用在传感器、换能器电路、静电传感器等方向,能够解决提高系统复杂度、增加元件等问题,达到简化结构和控制部件、减少元件的数量、优化数量的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

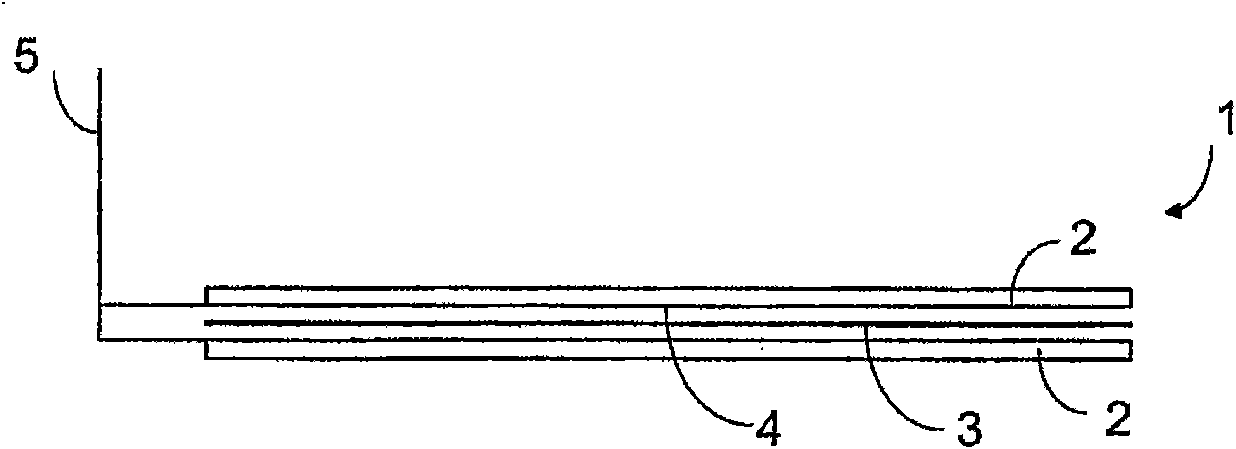

[0021] figure 1 Schematic diagram of the structure of an electrostatic driver, such as a loudspeaker. The electrostatic driver 1 includes at least one plate-shaped stator 2 and a movable diaphragm 3 . exist figure 1 In the shown embodiment there are two stators 2 between which the movable diaphragm 3 is arranged. Electrodes 4 are formed on the surface of the stator 2 . The signal is transmitted along the signal line 5 to the electrodes.

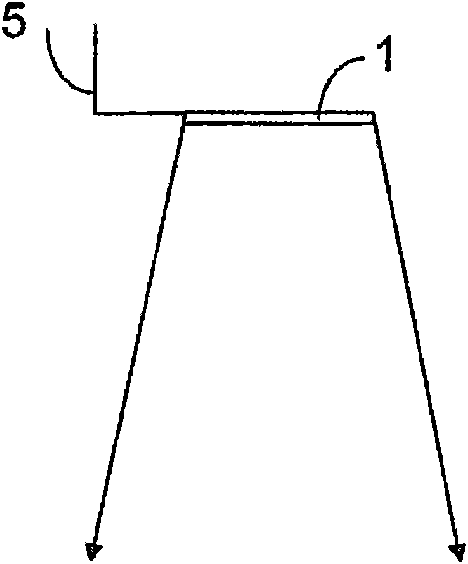

[0022] figure 2 The sound field formed by the electrostatic driver in the prior art is shown. In the solution of the prior art, the conductivity of the electrode 4 is very good, that is, the surface 4 of the stator 2 is conductive, such as a metal coating. In practice, there is no propagation delay for signals in electrostatic drivers, even when the signals are input at the edges of the driver. This forms as figure 2 sound field shown.

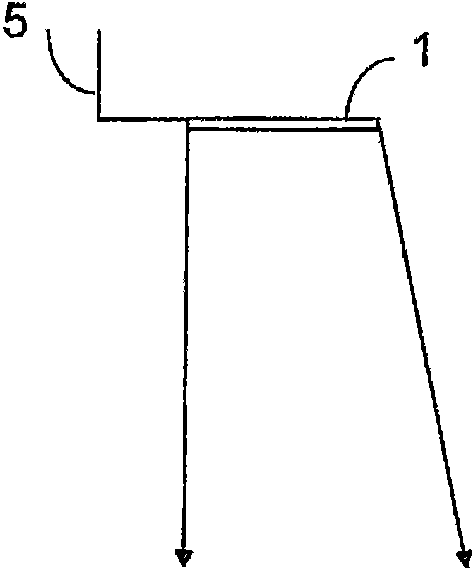

[0023] image 3 and Figure 4 It is a schematic diagram of a directional sound field formed b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com