Cleaning agent composite used after computer hard disk substrate polishing

The technology of a cleaning agent and composition is applied in the field of surface cleaning and treatment of computer hard disks, and can solve the problems of heavy surface roughness and excessive corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment one: in the present embodiment, the composition and the weight percent of the cleaning agent on the computer hard disk substrate surface after polishing are as follows:

[0021] Surfactant Lauryl Polyethylene Glycol 12%

[0022] ZETA potential regulator alkyl polyoxyethylene ether polyquaternary ammonium salt 5.0%

[0023] Corrosion inhibitor mercaptothiazole sodium salt 0.6%

[0025] Deionized water 82%

[0026] Preparation of cleaning agent: Under mechanical stirring, add surfactant, zeta potential regulator, corrosion inhibitor, and alkali into deionized water in sequence, stir and dissolve evenly, and the obtained transparent liquid is obtained.

[0027] After the above cleaning agent is diluted with deionized water at a ratio of 1:50, the polished Ni-P plated computer hard disk substrate is ultrasonically cleaned, the ultrasonic frequency is 100KHz, and the time is 10 minutes; the substrate is...

Embodiment 2

[0028] Embodiment two: In the present embodiment, the composition and weight percentage of the cleaning agent on the surface of the computer hard disk substrate after polishing are as follows:

[0029] Surfactant Lauryl Polyethylene Glycol 12%

[0030] ZETA Potential Regulator Alkyl Polyoxyethylene Ether-Phosphate Copolymer 5.0%

[0031] Corrosion inhibitor Hydroxybenzotriazole 0.6%

[0033] Deionized water 82%

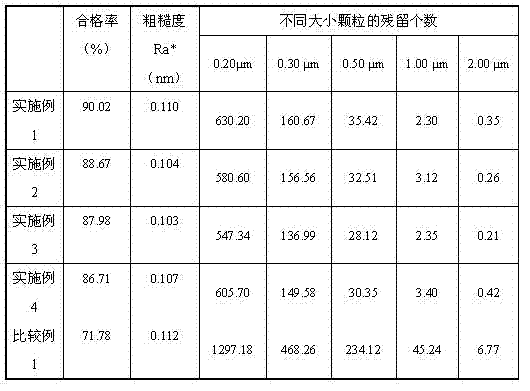

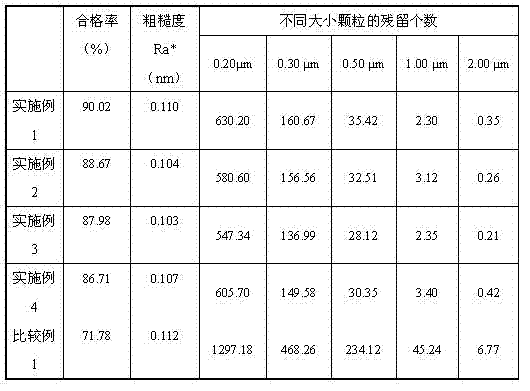

[0034] The cleaning agent preparation, cleaning process and surface detection process in this embodiment are the same as those in the above-mentioned embodiment 1. See the test results figure 1 .

Embodiment 3

[0035] Embodiment three: In the present embodiment, the composition and weight percentage of the cleaning agent on the surface of the computer hard disk substrate after polishing are as follows:

[0036] Surfactant Pingping plus O-20 12%

[0037] ZETA potential regulator polyoxyethylene ether sulfonate copolymer 5.0%

[0038] Corrosion inhibitor Hydroxybenzotriazole 0.6%

[0039] Sodium hydroxide 0.4%

[0040] Deionized water 82%

[0041] The cleaning agent preparation, cleaning process and surface detection process in this embodiment are the same as those in the above-mentioned embodiment 1. See the test results figure 1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com