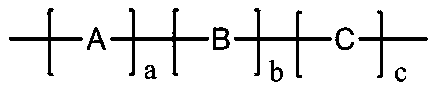

A highly adaptable polycarboxylate water reducer and its preparation method

An adaptive polycarboxylic acid technology, applied in the field of concrete admixtures, can solve the problems of poor slurry stability, inability to copolymerize, and poor workability, etc., and achieve the effects of reducing poor water retention, improving stability, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

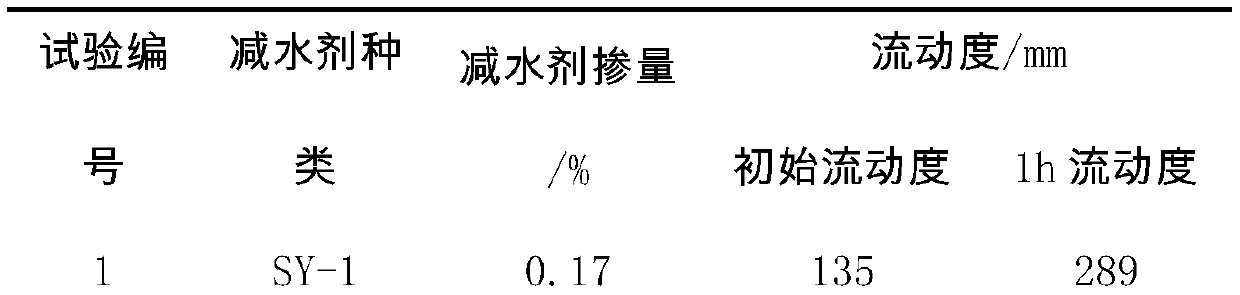

Examples

Embodiment 1

[0044] This example provides a highly adaptable polycarboxylate water reducer and its preparation method. Add 8 parts of nitrilotriacetic acid and 9.6 parts of trifluoromethanesulfonic acid into the reactor, raise the temperature to 30°C, and within 2 hours Add 3.6 parts of phosphorous acid into the reactor dropwise at a uniform speed, control the temperature during the dropping process to rise at 35°C / h, and keep it warm for 0.5h to obtain 2-(bis(phosphonomethyl)amino)acetic acid, 2,2'- The phosphonated product of ((phosphonomethyl) amino) diacetic acid and nitrilo trimethylene phosphonic acid; then 2.4 parts of isobutenol were added to the reactor, 0.15 parts of concentrated sulfuric acid, 0.012 parts of hydroquinone and 0.0021 parts of phenothiazine, heated up to 120°C, passed N 2 , and reacted for 4 hours to obtain the unsaturated ester monomer C containing phosphonic acid groups, which was taken out for later use; 100 parts of isobutylene alcohol polyoxyethylene ether (mole...

Embodiment 2

[0046] This example provides a highly adaptable polycarboxylate water reducer and its preparation method. Add 4.94 parts of nitrilotriacetic acid and 2.47 parts of trifluoromethanesulfonic acid into the reactor, raise the temperature to 30°C, and within 2 hours Add 4.94 parts of phosphorous acid into the reactor dropwise at a constant speed, control the temperature during the dropping process to rise at 35°C / h, keep it warm for 0.5h, and obtain 2-(bis(phosphonomethyl)amino)acetic acid, 2,2'- The phosphonated product of ((phosphonomethyl) amino) diacetic acid and nitrilo trimethylene phosphonic acid; Phenol and 0.003 parts of phenothiazine, the temperature was raised to 120°C, and N 2 , and reacted for 4 hours to obtain unsaturated ester monomers containing phosphonic acid groups, which were taken out for later use; 100 parts of prenol polyoxyethylene ether (molecular weight 2400) and several parts of water were put into the reactor to dissolve completely , mix and dissolve th...

Embodiment 3

[0048] This example provides a highly adaptable polycarboxylate water reducer and its preparation method. Add 2.87 parts of nitrilotriacetic acid and 5.7 parts of trifluoromethanesulfonic acid into the reactor, raise the temperature to 30°C, Add 8.6 parts of phosphinic acid dropwise to the reactor at a constant speed, control the temperature during the dropping process to rise at 35°C / h, keep it warm for 0.5h, and obtain 2-(bis(phosphonomethyl)amino)acetic acid, 2,2 The phosphonated product of '-((phosphonomethyl) amino) diacetic acid and nitrilo trimethylene phosphonic acid; then 2.4 parts of isobutenol were added to the reactor, 0.24 parts of concentrated sulfuric acid, 0.04 parts of terephthalic acid Phenol and 0.008 parts of phenothiazine, the temperature was raised to 120°C, and N 2 , and reacted for 4 hours to obtain the unsaturated ester monomer C containing phosphonic acid groups, which was taken out for later use; 100 parts of isobutylene alcohol polyoxyethylene ether...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com