A kind of plastic-preserving and anti-mud type dispersant and preparation method thereof

A dispersant and anti-mud type technology, applied in the field of dispersant and cement dispersant, can solve the problems of less than 1% anti-mud effect and poor plastic retention of products, and meet the requirements of construction environment, durable plastic retention performance, The effect of expanding the range of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

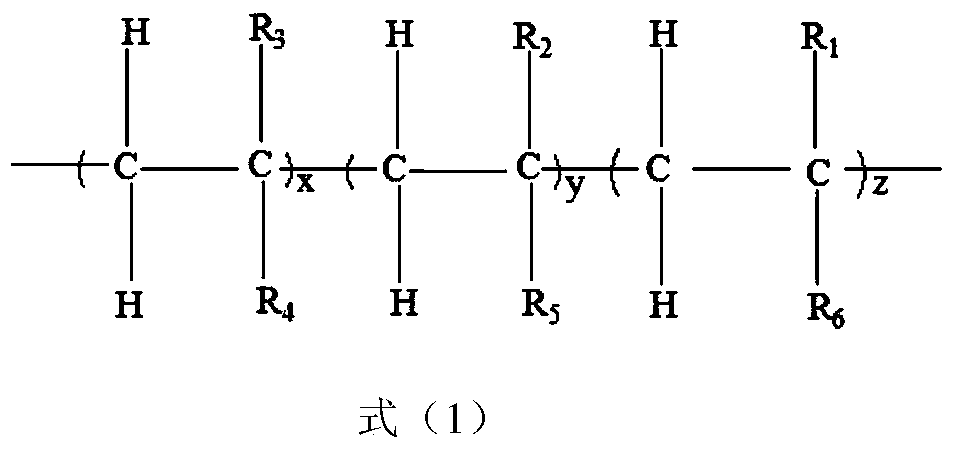

Method used

Image

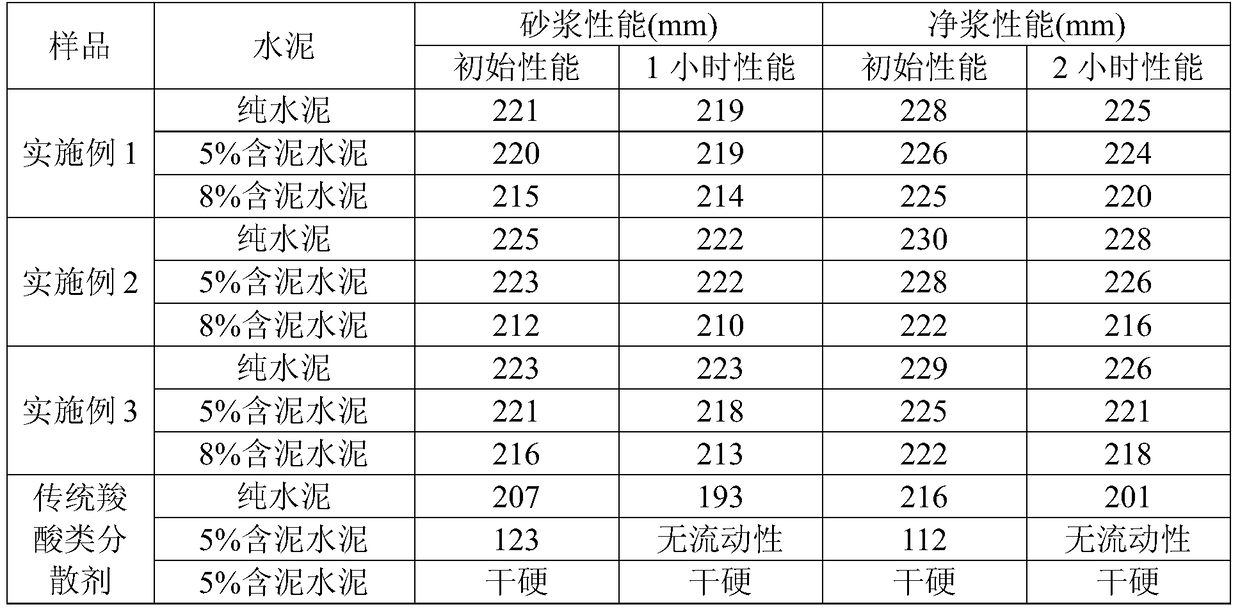

Examples

Embodiment 1

[0022] The preparation of embodiment 1 dispersant

[0023] 1), amidated polyethyleneimine: 10 grams of acrylic acid and 100 grams of polyethyleneimine aqueous solution (molecular weight 3500, solid content 50%, polyethyleneimine macromonomer is prepared into aqueous solution in advance, the concentration of aqueous solution Little impact on the quality of the product of the present invention, can be appropriately controlled) and 0.2 gram of hydroquinone mixed and stirred evenly, reacted at 190 DEG C and simultaneously removed water vapor, reacted for 1 to 3 hours, cooled to obtain polymerizable macromonomer 1 . In order to improve the reactivity of later-stage products, the polymerizable macromonomer 1 can be diluted with water to form a 60% aqueous solution after cooling to below 98°C, and then used for later-stage polymerization;

[0024] 2), esterified polyethylene glycol monomethyl ether: add 0.33 gram of hydroquinone in 100 grams of molten polyethylene glycol monomethyl ...

Embodiment 2

[0026] The preparation of embodiment 2 dispersants

[0027] 1), amidated polyethyleneimine: 7.93 grams of methacrylic acid and 714 grams of polyethyleneimine aqueous solution (molecular weight 25000, solid content 50%) and 0.79 grams of hydroquinone were mixed and stirred evenly, at 130 ℃ React while removing water vapor, react for 1 to 3 hours, and cool to obtain the polymerizable macromonomer 1. In order to improve the reactivity of later-stage products, the polymerizable macromonomer 1 can be diluted with water to form a 60% aqueous solution after cooling to below 98°C, and then used for later-stage polymerization;

[0028] 2), esterified polyethylene glycol monomethyl ether: add 0.167 gram of hydroquinone in 100 grams of molten polyethylene glycol monomethyl ether (molecular weight 1000) and stir well, then slowly add 0.2 gram of concentrated sulfuric acid, stir After uniformity, add 10 grams of methacrylic acid and stir evenly. After the temperature was raised to 145°C,...

Embodiment 3

[0030] The preparation of embodiment 3 dispersants

[0031] 1), amidated polyethyleneimine: 6 grams of methacrylic acid and 300 grams of polyethyleneimine (molecular weight 15000, solid content 50%) and 0.43 grams of hydroquinone aqueous solution are mixed and stirred evenly, at 150 ℃ React while removing water vapor, react for 1 to 3 hours, and cool to obtain the polymerizable macromonomer 1. In order to improve the reactivity of later-stage products, the polymerizable macromonomer 1 can be diluted with water to form a 60% aqueous solution after cooling to below 98°C, and then used for later-stage polymerization;

[0032] 2), esterified polyethylene glycol monomethyl ether: add 0.222 gram of hydroquinone in 100 grams of molten polyethylene glycol monomethyl ether (molecular weight 2400) and stir evenly, then slowly add 0.333 gram of concentrated sulfuric acid, stir After uniformity, 16.67 grams of acrylic acid was added and stirred evenly. After the temperature was raised t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com