Large-diameter engineering well holing construction method in super-thick pebble formation

A construction method, pebble floating technology, which is applied in the field of large-diameter engineering well hole-forming construction, can solve the problems of low hole-forming efficiency and drilling tool wear, and achieve the effects of short well-forming period, fast construction progress and high economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

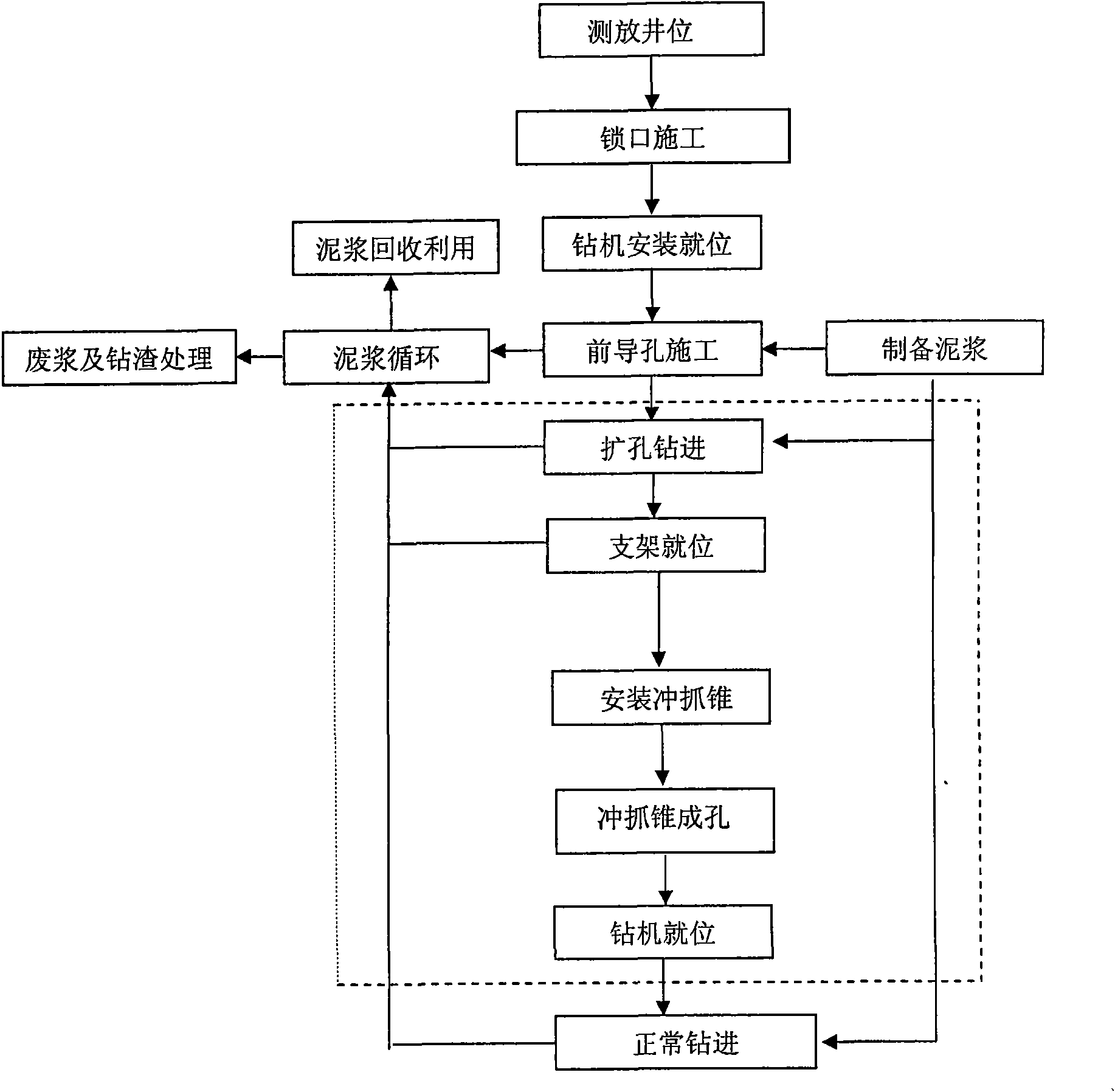

Method used

Image

Examples

Embodiment 1

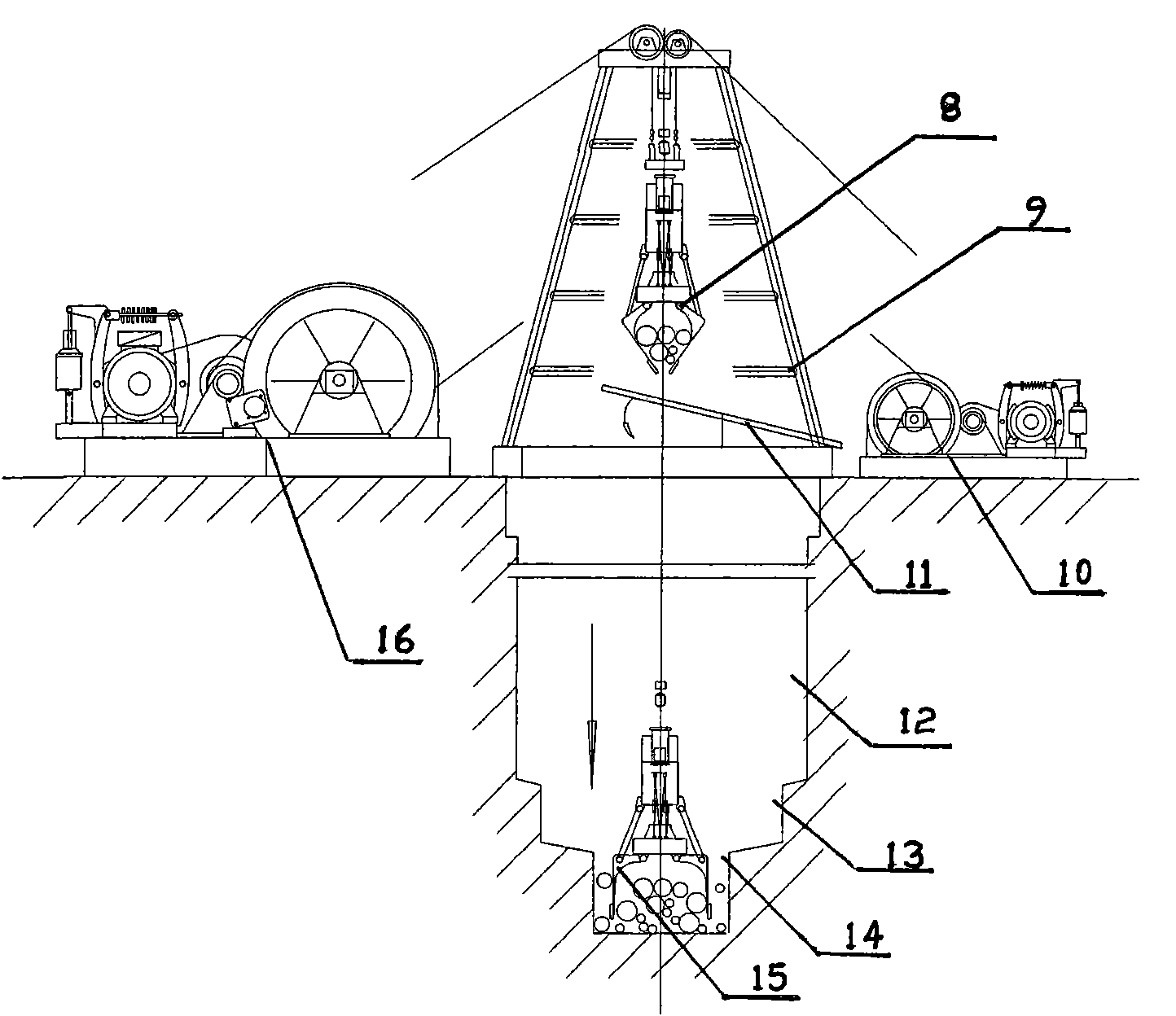

[0042]The shaft project of Zunhua Wenjiazhuang Iron Mine has a drilling diameter of 8.3m and a drilling depth of 285m. At 231.6-251.0m is the floating pebble layer, the maximum visible particle size is 102cm (the drill bit is carried to the surface when the drill is lifted), and generally 20-80cm. The main component of the floating pebble is quartzite, which is extremely strong and difficult to break. The layers are filled with cohesive soil.

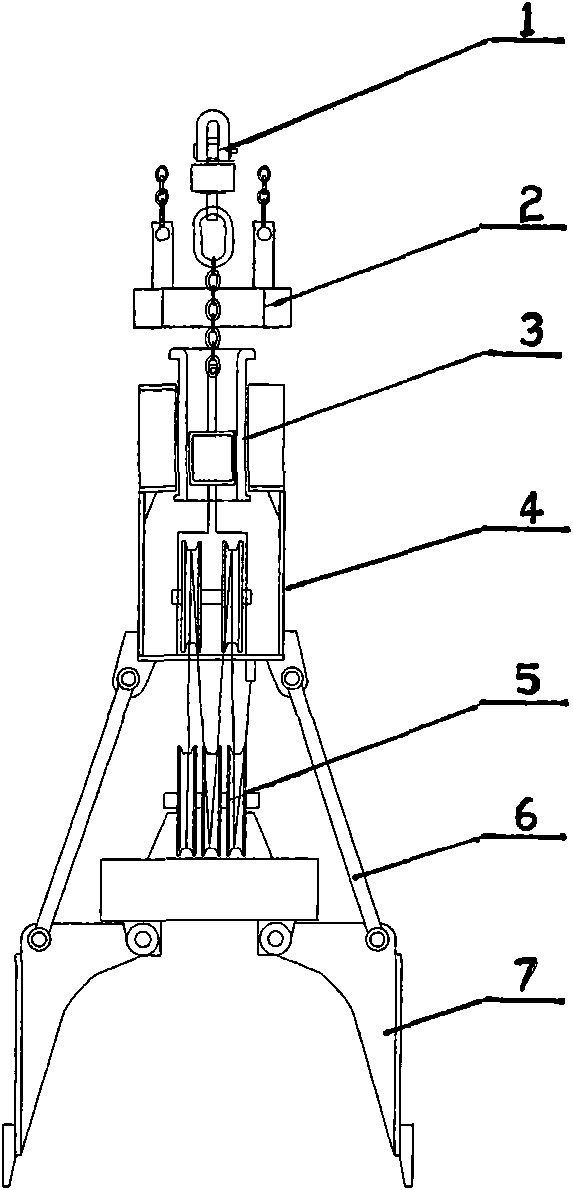

[0043] This layer adopts AD-60 drilling rig to drill the leading hole. The main technical parameters of the drilling rig are shown in Table 2. The drilling diameter is 3.5m and the drilling depth is 285m. After the pilot hole is finished, replace the φ6.3m drill bit for primary reaming, and drop part of the drilling slag and boulders into the pilot hole. After the front pilot hole is filled, lift the drill to move the drill away from the hole, and then install the punching cone bracket. The technical parameters of the bracket are lis...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap