Self-adaptive liquid accumulator with vapor bubble injection function

A liquid storage and bubble technology, applied in the field of adaptive liquid storage, can solve the problems of system instability, overheating of cooling equipment, pressure pulse, etc., and achieve the effect of small comprehensive use space, suppression of overheating phenomenon, and stable temperature environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

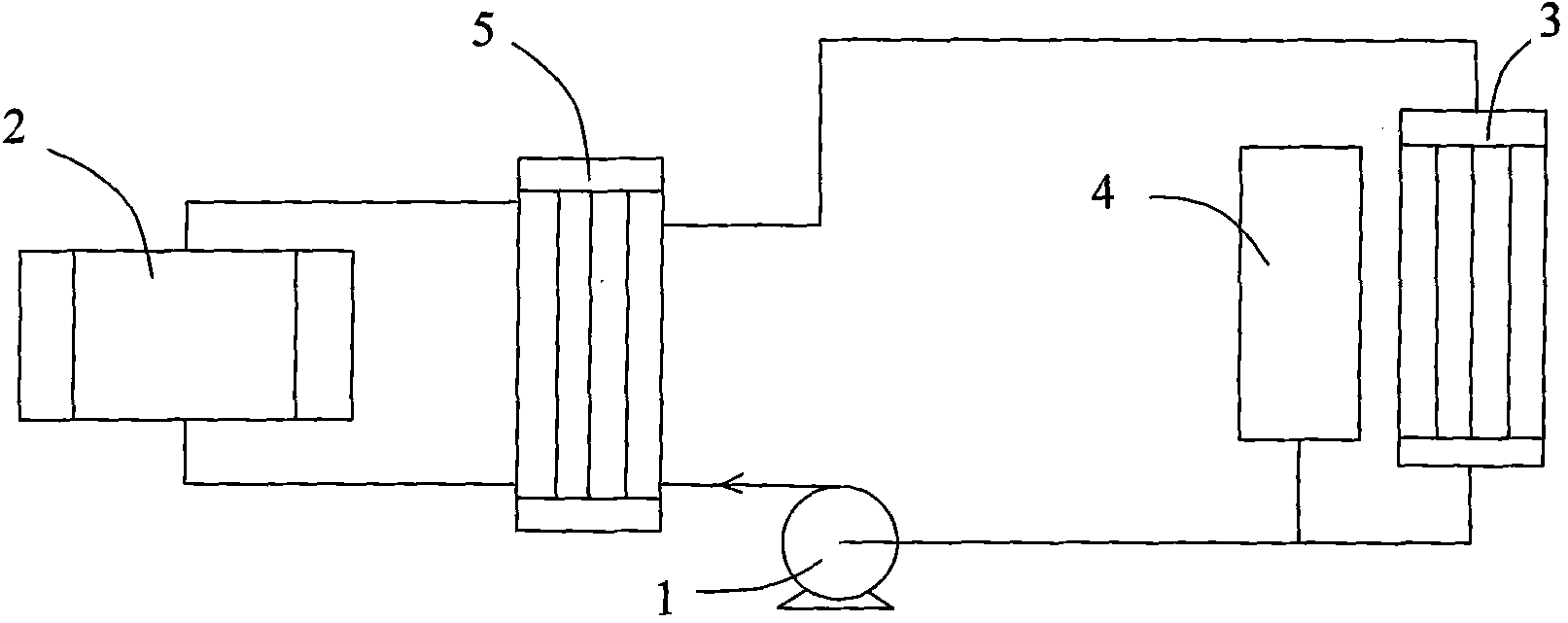

Embodiment 1

[0046] like image 3 As shown, in the liquid accumulator 10 of one embodiment of the present invention, the liquid pipe (small pipe) 11 is passed through the accumulator pressure vessel, and then a small opening (the first opening) is opened on the liquid pipe 11 near the liquid outlet 12 inside the container. ), and at the same time extend the first opening to the vapor phase area inside the container (usually the upper part of the container, the height of which is determined according to the design needs) with the first opening extension tube 13, the liquid pipe 11 inside the liquid storage tank 10 has the liquid The inlet end is connected to the outlet of the pump, and the other end of the liquid outlet 12 (near the open end of the pipe) is connected to the inlet of the evaporator; when the liquid at the inlet reaches the saturation temperature, the low pressure and the two-phase loop generated by the flow of the liquid in the liquid pipe 11 Due to its own pressure oscillat...

Embodiment 2

[0048] like Figure 4 As shown, in another embodiment of the liquid accumulator 20 of the present invention, a liquid pipe (small pipe) 21 is passed through the accumulator pressure vessel, and a small pipe 23 with a first opening is used to extend the first opening to the vapor phase region inside the container (usually the upper part of the container, the height of which depends on the design requirements), add a thicker pipe passing through the liquid reservoir 20, preferably, the outer wall of the pipe is welded with heat dissipation fins, and the pipe and the container are only There is no working medium exchange channel (opening) for heat exchange, the inlet 24 of the two-phase pipe (thick pipe) is connected to the inlet and outlet of the evaporator, and the liquid outlet 22 is connected to the inlet of the hot side of the condenser. Through the thick pipe, there is good heat exchange with the vapor-liquid two-phase fluid from the evaporator and the liquid accumulator, s...

Embodiment 3

[0050] In practical application, in order to prevent the cavitation of the mechanical pump, the fluid sucked into the mechanical pump must have a certain degree of subcooling; when the supercooled liquid is pumped into the liquid thin tube passing through the pressure vessel, the subcooled liquid will be separated from the inside of the container. The heat exchange of the working medium can reduce the temperature of the working medium in the container, thereby reducing the working temperature of the accumulator. Not all working conditions can accept this effect. One of the solutions is to install a heater outside or inside the container to maintain the temperature of the reservoir, that is, the operating temperature of the system, but this consumes a lot of energy and increases the complexity of the temperature control system.

[0051] like Figure 5 As shown, in order to further reduce the heat exchange between the subcooled liquid and the working fluid inside the accumulator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com