Automatic control system for oil well tipping bucket measurement

An automatic control system and control system technology, applied in weighing, measuring devices, instruments, etc., can solve the problems of non-standardized placement, inconvenient operation, unreliability, etc., to facilitate analysis, monitoring and processing, improve maintenance efficiency, The effect of preventing safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

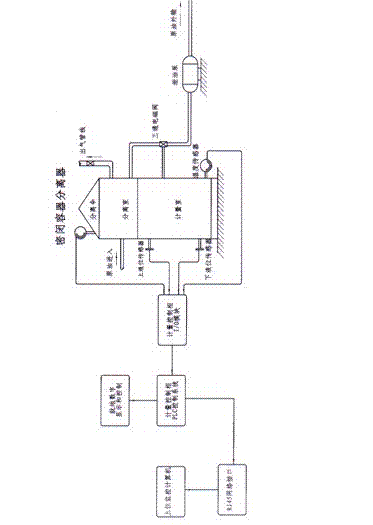

[0021] An automatic control system for oil well dump metering, comprising a metering control cabinet and an upper monitoring computer, a temperature sensor and a liquid level sensor are arranged on the separation umbrella of the metering control cabinet, and the temperature sensor and the liquid level sensor are connected to the metering control cabinet PLC control system, the PLC control system is connected to the upper monitoring computer, the PLC control system receives the collected information from the temperature sensor and the liquid level sensor, and the upper monitoring computer is used to receive the information sent by the PLC control system.

[0022] In the present invention, the separation umbrella includes a separation chamber and a metering chamber, the separation chamber is provided with a crude oil inlet pipe and an exhaust pipe, the separation chamber is provided with an oil-gas separation buffer device, and the metering chamber is provided with a tipping buc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com