Preparation method of molecularly imprinted material on attapulgite surface modified by silane coupling agent for bisphenol A

A technology of surface molecular imprinting and silane coupling agent, applied in the field of preparation of silane coupling agent modified attapulgite surface molecularly imprinted material, can solve the problem of uneven imprinted binding sites, poor controllability and poor accessibility of the grinding process and other problems, to achieve the effect of reducing the "encapsulation" phenomenon, improving accessibility, and strong targeted adsorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

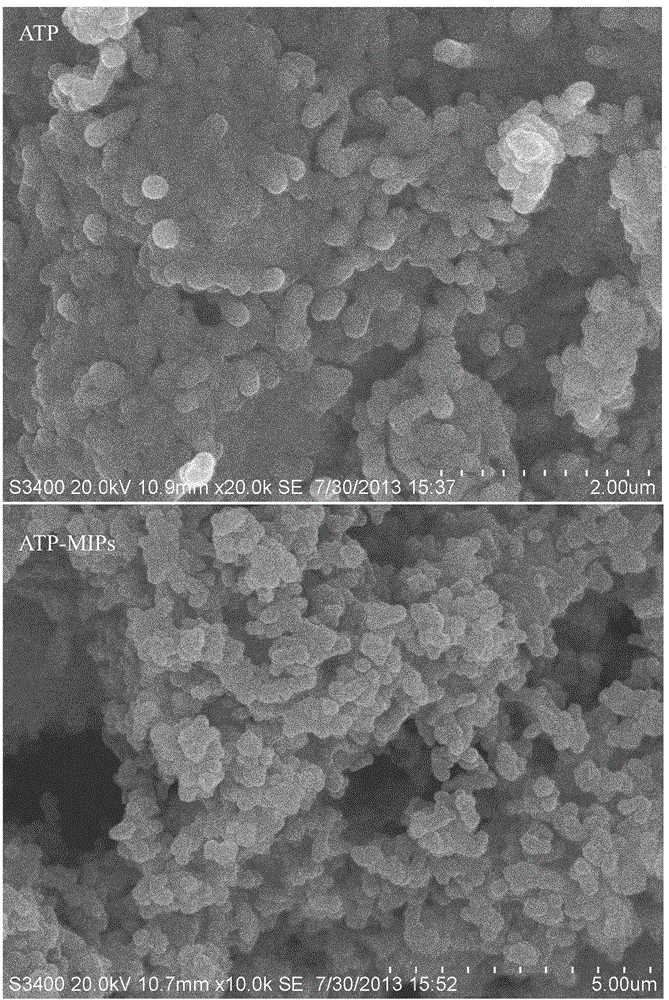

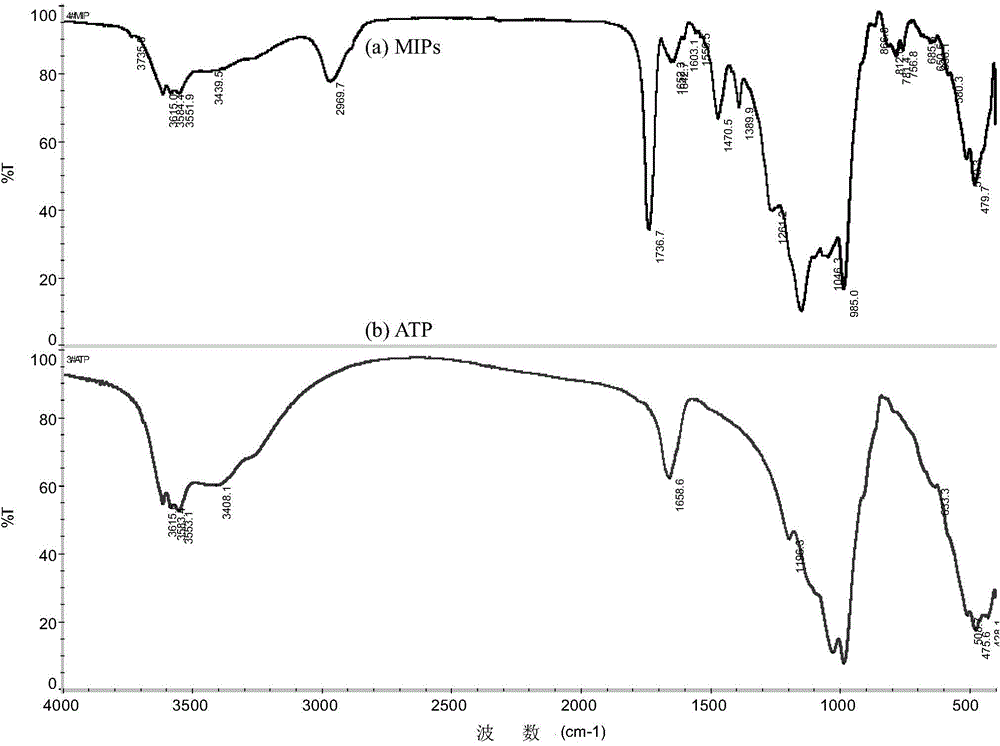

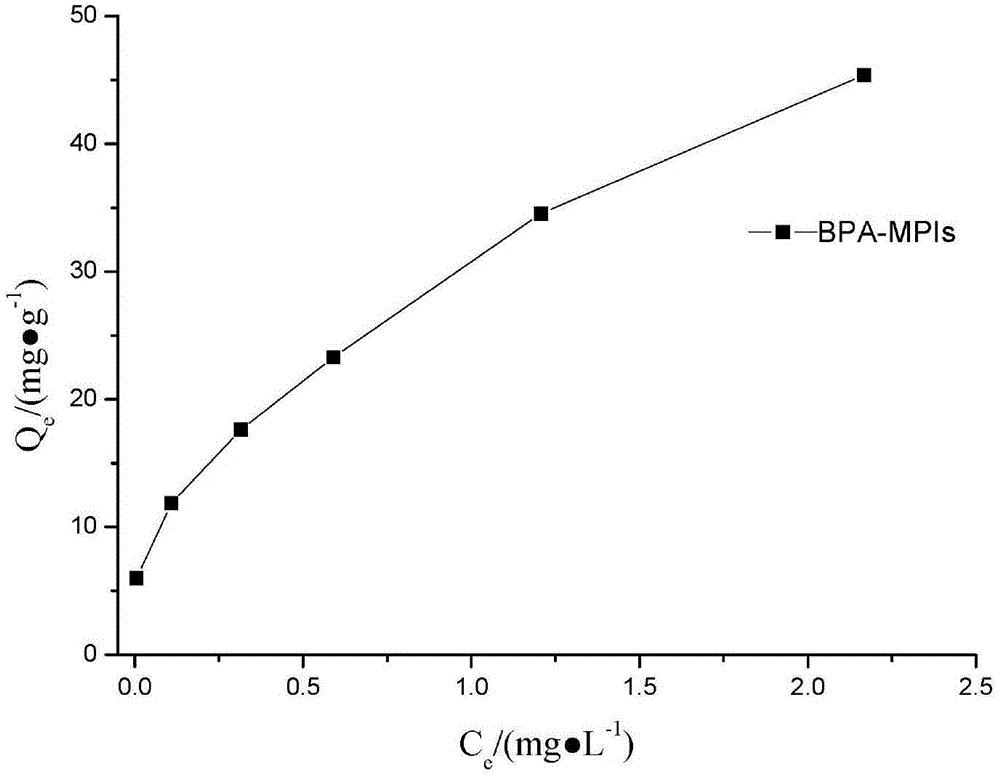

[0025] A method for preparing a molecularly imprinted material on the surface of attapulgite modified with a silane coupling agent for bisphenol A, specifically comprising the following steps: (1) Purification of attapulgite raw soil, accurately weighing 2.400g of sodium hexametaphosphate in 800mL After fully dissolving in distilled water, add 40.000g of attapulgite raw soil, place in a constant temperature water bath at 50°C, stir for 2 hours, and ultrasonically disperse for 0.5 hours. After standing for 24 hours, centrifuge, dry, grind and sieve to obtain purified attapulgite; (2) Weigh 10g of purified attapulgite in 100mL of 6mol / L HCl solution at 80°C for 1 hour under constant temperature magnetic stirring and reflux, vacuum filter, wash with ultrapure water until the lotion is neutral, and dry under vacuum at 105°C for 2 hours to obtain acidified Attapulgite; (3) Add 10g of acidified attapulgite and 200mL of distilled water into a 500mL beaker in sequence, and apply ultras...

Embodiment 2

[0036] A method for preparing a molecularly imprinted material on the surface of attapulgite modified with a silane coupling agent for bisphenol A, specifically comprising the following steps: (1) purification of attapulgite raw soil; (2) weighing 10 g of purified attapulgite in 100mL of 6mol / L HCl solution was refluxed at 80°C for 1 hour under constant temperature magnetic stirring, vacuum filtered, washed with ultrapure water until the lotion was neutral, and dried in vacuum at 105°C for 2 hours to obtain acidified attapulgite; (3) in a 500mL beaker Add 10g of acidified attapulgite and 200mL of distilled water in sequence, and apply ultrasound for 15 minutes; adjust the pH=4 to 6, and add 2g of γ-glycidoxypropyltrimethoxysilane coupling agent; and react with magnetic force in a water bath at 80°C for 5 hours. After suction filtration, washing with distilled water and ethanol, and centrifugation, vacuum-dry at 50-60°C to obtain epoxy silane coupling agent modified attapulgite;...

Embodiment 3

[0038] A method for preparing a molecularly imprinted material on the surface of attapulgite modified with a silane coupling agent for bisphenol A, specifically comprising the following steps: (1) purification of attapulgite raw soil; (2) weighing 10 g of purified attapulgite in 100mL of 6mol / L HCl solution was refluxed at 80°C for 1 hour under constant temperature magnetic stirring, vacuum filtered, washed with ultrapure water until the lotion was neutral, and dried in vacuum at 105°C for 2 hours to obtain acidified attapulgite; (3) in a 500mL beaker Add 10g of acidified attapulgite and 200mL of distilled water in sequence, and apply ultrasound for 15 minutes; adjust the pH=4 to 6, and add 2g of glycidoxypropylmethyldiethoxysilane coupling agent; stir magnetically in a water bath at 80°C After reacting for 5 hours, after suction filtration, washing with distilled water and ethanol, and centrifugation, vacuum-dry at 50-60°C to obtain epoxy silane coupling agent modified attapul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com