Heat conductivity coefficient quick test device and method of vacuum insulating board

A technology of vacuum insulation panels and thermal conductivity, applied in the direction of material thermal development, etc., can solve the problems of not more than the test requirements, time-consuming vacuum insulation panels, and harsh test requirements, etc., to shorten the time for sample replacement, shorten the time for thermal equilibrium, Significant energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

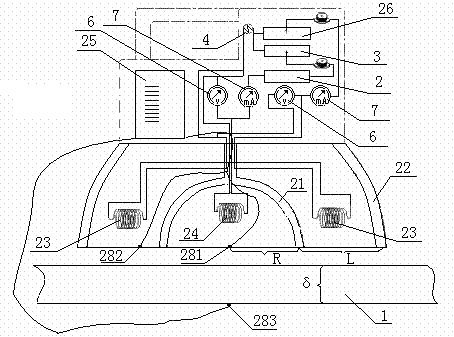

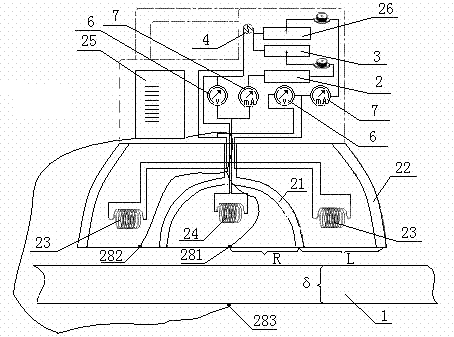

[0020] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the following is attached figure 2 , The structural principle of the present invention is further described in detail.

[0021] Such as figure 2 As shown, the thermal conductivity test device for vacuum insulation panels of the present invention includes a power supply 4, a temperature acquisition and data processing device 25, and a test hemisphere 8. The test hemisphere 8 includes an inner hemisphere 21, an outer hemisphere 22, and a bottom plate 27. The hemisphere 21 and the outer hemisphere 22 are concentric. In order to ensure the uniformity of the internal temperature field distribution of the test device, the inner and outer hemispheres of the device are filled with fluids with good heat capacity and thermal conductivity (such as water, glycol, grease, etc.). The bottom plate 27 seals the inner hemisphere 21 and the outer hemisphere 22. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com