Method for monitoring thermal efficiency and coal quality data of pulverized coal fired boiler in real time

A boiler thermal efficiency, pulverized coal boiler technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problem that the real-time monitoring of boiler operation adjustment has not yet been realized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0141] The present invention will be further described below using specific embodiments.

[0142] A method for real-time monitoring of thermal efficiency and coal quality data of a pulverized coal boiler, which includes the following contents:

[0143] 〔1〕Establish a mathematical model for real-time monitoring of thermal efficiency of pulverized coal boiler system:

[0144] Relationship between Thermal Efficiency and Heat Loss of Pulverized Coal Boiler

[0145] Boiler thermal efficiency η b (%) is calculated by formula (1)

[0146] n b =100-(q 2 +q 3 +q 4 +q 5 +q 6 ) (1)

[0147] Among them, q 2 ,q 3 ,q 4 ,q 5 ,q 6 They are exhaust heat loss (%) of pulverized coal boiler, chemical unburned heat loss (%), mechanical unburned heat loss (%), boiler heat dissipation loss (%), and ash physical heat loss (%).

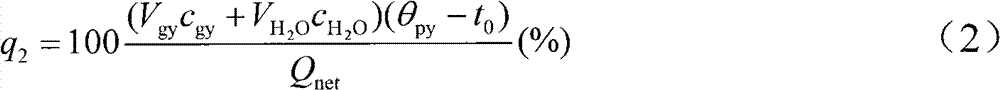

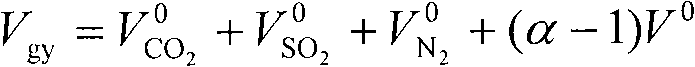

[0148] Exhaust heat loss q 2 (%) is calculated by formula (2)

[0149] q 2 = 100 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com